Eccentric shearing type low-impact expansion pipe double-groove plate separation device

A separation device and low-impact technology, applied in the aerospace field, can solve the problems of reduced reliability, inability to meet usage requirements, and increased use of point-type separation devices. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments disclosed in the present invention will be further described in detail below in conjunction with the accompanying drawings.

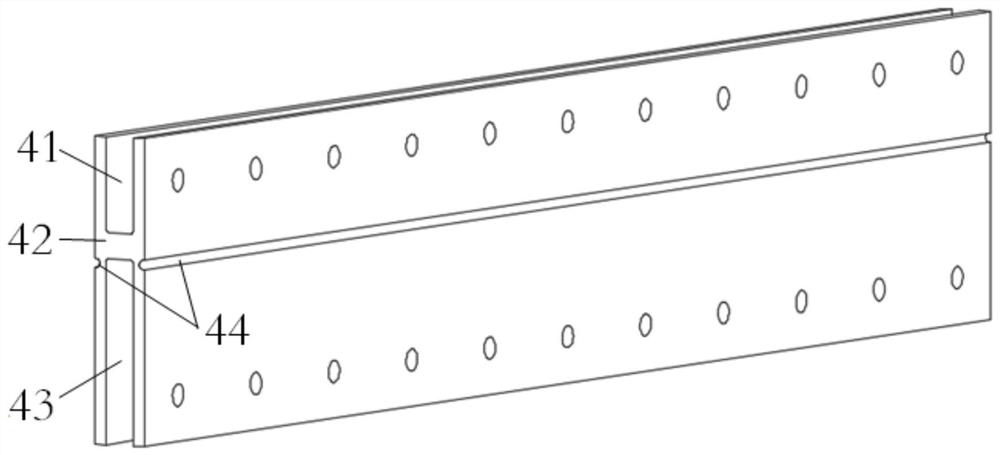

[0036] Such as figure 1 with figure 2 , in this embodiment, the eccentric shear type low-impact expansion tube double-groove plate separation device includes: explosive cord 1, filler 2, flat tube 3, H-shaped separation plate 4, upper end frame 51, lower end frame 52 , Upper fastening bolt 61 and lower fastening bolt 62. Further, such as image 3 As shown, the H-shaped separation plate 4 can specifically include: an upper U-shaped groove 41, a lower U-shaped groove 42 and a connection area 43; side.

[0037] The connection of each structure is as follows: the upper end frame 51 is docked with the upper U-shaped groove 41 and fastened by the upper fastening bolt 61; the lower end frame 52 is docked and installed with the lower U-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com