A cyclone separator automatic control system and method

An automatic control system, cyclone separator technology, applied in the direction of electrical program control, program control in sequence/logic controller, sustainable manufacturing/processing, etc., can solve the problems of poor separation effect and efficiency, simple working mode, etc. Achieve the effects of low maintenance cost, high power consumption, and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

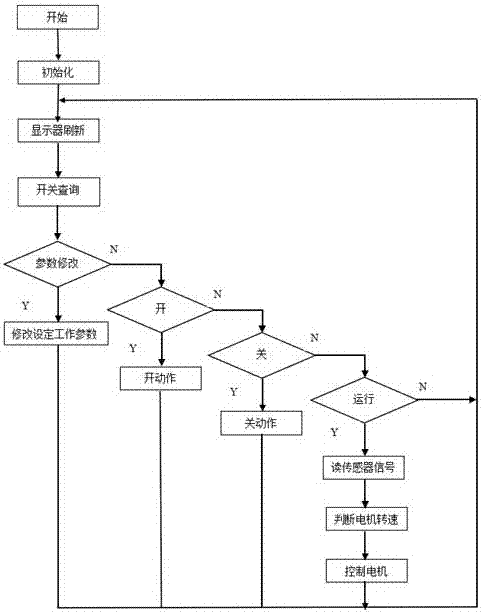

[0045] Further description below in conjunction with accompanying drawings.

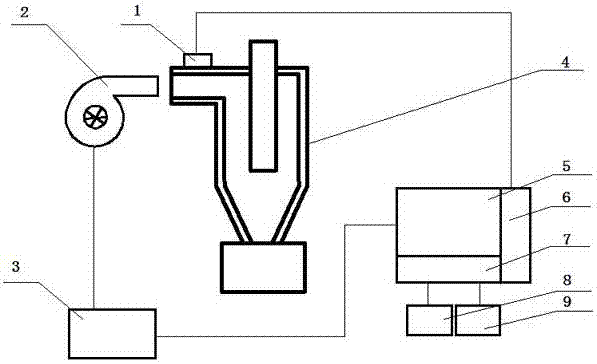

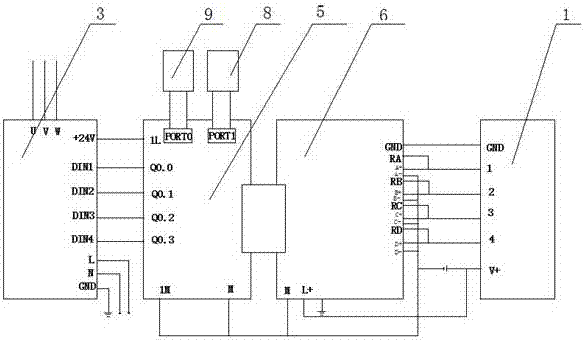

[0046] An automatic control system for a cyclone separator, including a dust concentration and particle size sensor 1, a motor 2, a frequency converter 3, a cyclone separator 4, a controller 5, an A / D conversion module 6, a communication interface 7, a programming device 8, and a display 9. The dust concentration and particle size sensor 1 is located at the external entrance of the cyclone separator 4, and the dust concentration and particle size sensor 1 is connected to the input end of the controller 5 through the A / D conversion module 6, The controller 5 controls the start-stop and rotational speed of the motor 2 through the frequency converter 3 , the motor 2 is connected to the cyclone separator 4 , and the controller 5 has a communication interface 7 connected to the display 9 . The controller 5 has a programming device 8 for programming, and the programming device 8 is connected to the communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com