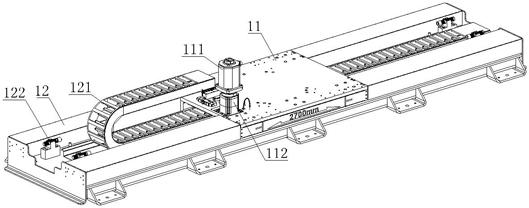

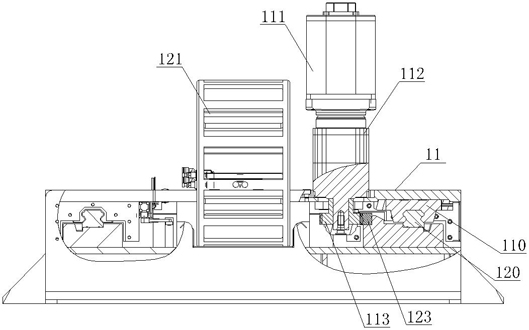

A flexible assembly welding system and method for standard parts and non-standard parts

A technology for non-standard parts and welding systems, applied in welding equipment, welding equipment, auxiliary welding equipment, etc. The effect of wide object range, improved assembly accuracy and high assembly welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] A method for a flexible assembly welding system for standard parts and non-standard parts, the method includes the following steps:

[0082] Step 1: Determine the shape and size of each workpiece in standard or non-standard parts;

[0083] Step 2: After determining the shape and size of each workpiece in the standard part or non-standard part, the robotic arm of the robot 1 cooperates with the magnetic gripper assembly 101 of the positioning fixture, and grabs the rotary platform plate through the magnetic gripper assembly 101 of the positioning fixture for positioning The magnet 60, the angle rib positioning body 61, the rotary platform tube rod positioning body 62 or the above-mentioned combination are used to delineate the outline of each workpiece on the double-station flexible positioning rotary platform 4; the above-mentioned rotary platform plate positioning magnet 60, angle The rib positioning body 61, the rotary platform tube rod positioning body 62 or the comb...

Embodiment 2

[0091] A method for a flexible assembly welding system for standard parts and non-standard parts, the method includes the following steps:

[0092] Step 1: Determine the shape and size of each workpiece in standard or non-standard parts;

[0093] Step 2: After determining the shape and size of each workpiece in the standard part or non-standard part, the robotic arm of the robot 1 cooperates with the magnetic gripper assembly 101 of the positioning fixture, and grabs the rotary platform plate through the magnetic gripper assembly 101 of the positioning fixture for positioning The magnet 60, the angle rib positioning body 61, the rotary platform tube rod positioning body 62 or the above-mentioned combination are used to delineate the outline of each workpiece on the double-station flexible positioning rotary platform 4; the above-mentioned rotary platform plate positioning magnet 60, angle The rib positioning body 61, the rotary platform tube rod positioning body 62 or the comb...

Embodiment 3

[0102] A method for a flexible assembly welding system for standard parts and non-standard parts, the method includes the following steps:

[0103] Step 1: Determine the shape and size of each workpiece in standard or non-standard parts;

[0104] Step 2: After determining the shape and size of each workpiece in the standard part or non-standard part, the robotic arm of the robot 1 cooperates with the magnetic gripper assembly 101 of the positioning fixture, and grabs the rotary platform plate through the magnetic gripper assembly 101 of the positioning fixture for positioning The magnet 60, the angle rib positioning body 61, the rotary platform tube rod positioning body 62 or the above-mentioned combination are used to delineate the outline of each workpiece on the double-station flexible positioning rotary platform 4; the above-mentioned rotary platform plate positioning magnet 60, angle The rib positioning body 61, the rotary platform tube rod positioning body 62 or the comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com