Iron plate plasma punching equipment

A punching equipment, plasma technology, applied in the direction of plasma welding equipment, welding equipment, welding equipment, etc., can solve the inconvenience of punching iron plates of different sizes, fixing iron plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

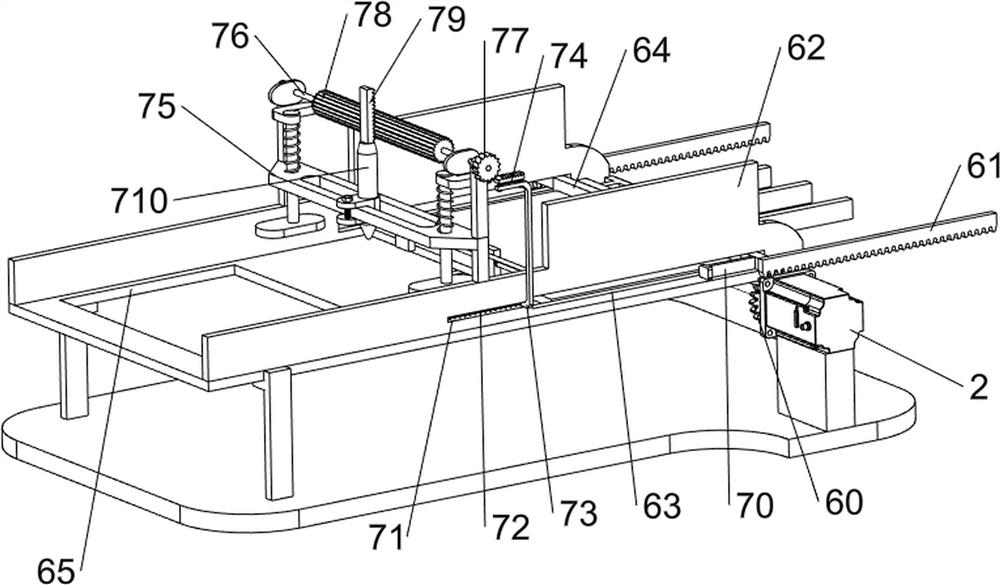

[0026] A kind of iron plate plasma drilling equipment, such as figure 1 with figure 2 As shown, it includes a bottom plate 1, a servo motor 2, a bracket 3, a placement plate 4, a material frame 5, a pushing mechanism 6 and a punching mechanism 7, a servo motor 2 is provided on the top right front side of the bottom plate 1, and multiple A support 3 is provided with a placement plate 4 between the supports 3, the right side of the placement plate 4 top is provided with a material frame 5, the placement plate 4 is provided with a pushing mechanism 6, and the placement plate 4 is provided with a punching mechanism 7.

[0027] When people need to use this equipment, first people place an iron plate in the material frame 5, and then people can start the servo motor 2 and the punching mechanism 7, and the servo motor 2 drives the pushing mechanism 6 to operate, and the pushing mechanism 6 The operation further drives the iron plate to move to the left, and then when the pushing me...

Embodiment 2

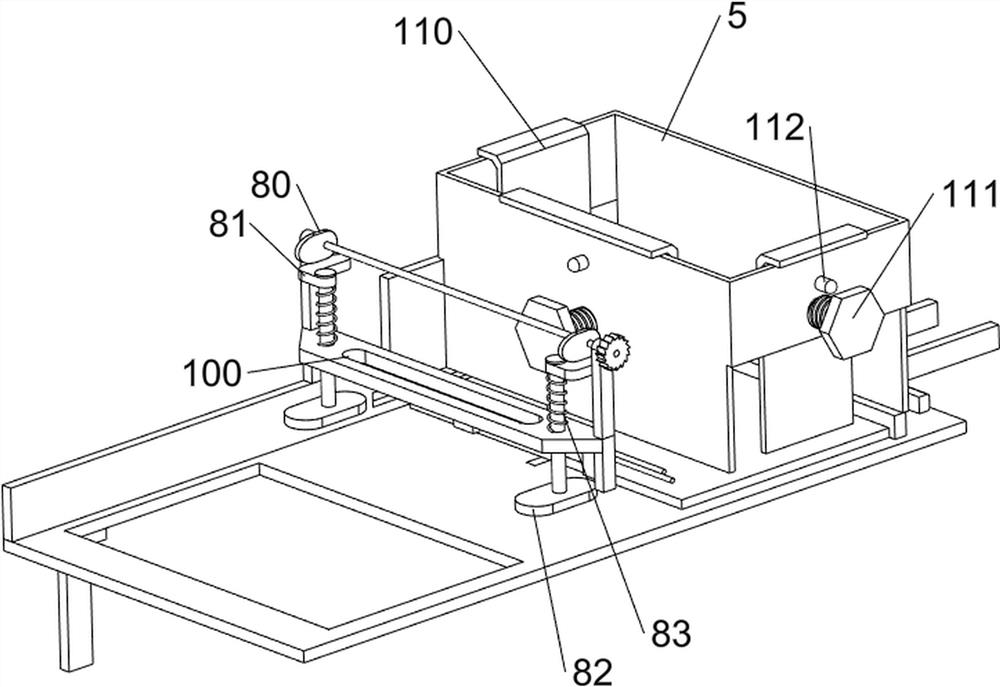

[0033] On the basis of Example 1, such as figure 1 , image 3 with Figure 4 Shown, also comprise hold-down mechanism 8, hold-down mechanism 8 comprises cam 80, special-shaped piece 81, pressing plate 82 and second spring 83, and cam 80 is provided with front and back symmetry on first rotating shaft 76, and front and back symmetry slides on fixed mount 75 Formula is provided with pressing plate 82, and pressing plate 82 tops are all provided with special-shaped block 81, and cam 80 cooperates with special-shaped block 81, and pressing plate 82 is all provided with second spring 83, and second spring 83 is connected with special-shaped block 81 and fixed mount 75.

[0034] When the first rotating shaft 76 rotates, the first rotating shaft 76 drives the cam 80 to rotate, and when the convex part of the cam 80 contacts the special-shaped block 81, the cam 80 squeezes the special-shaped block 81, and then the special-shaped block 81 moves downward, and the special-shaped block 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com