Hot melting forming device for packing box for placing polystyrene red wine glass

A packaging box, Lilonghong technology, applied in metal processing and other directions, can solve the problem of inconvenient waste disposal and collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

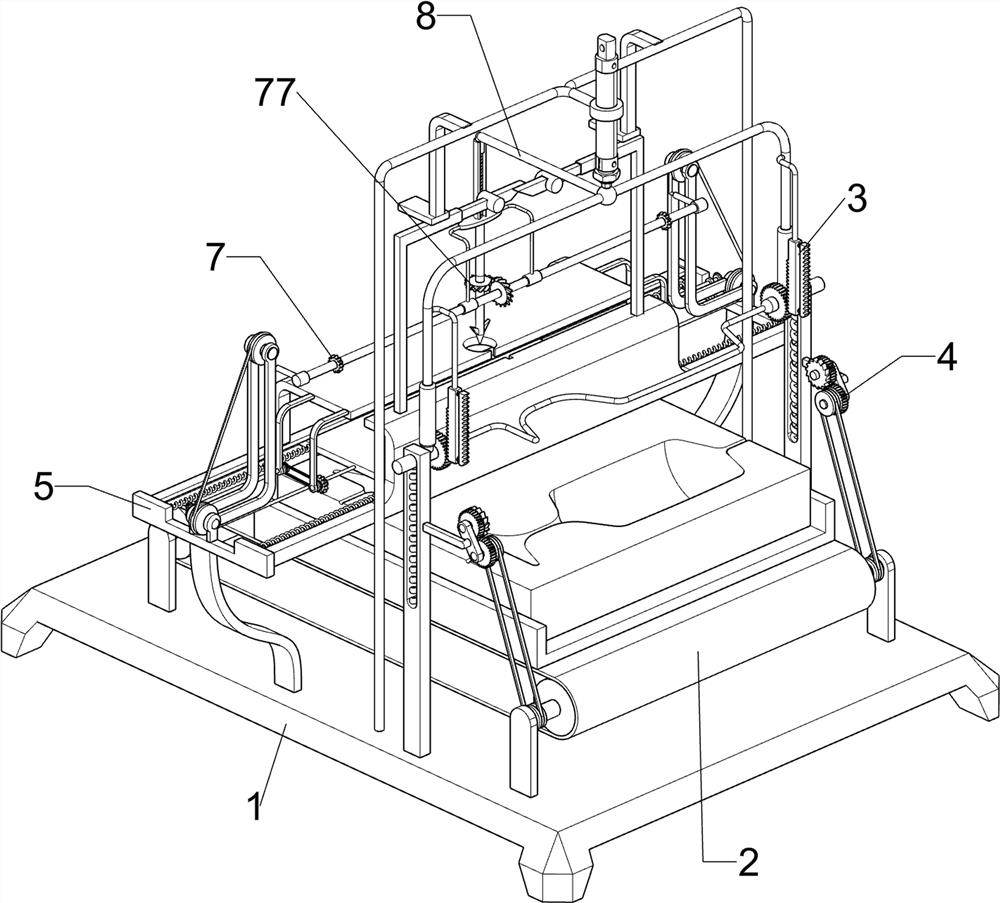

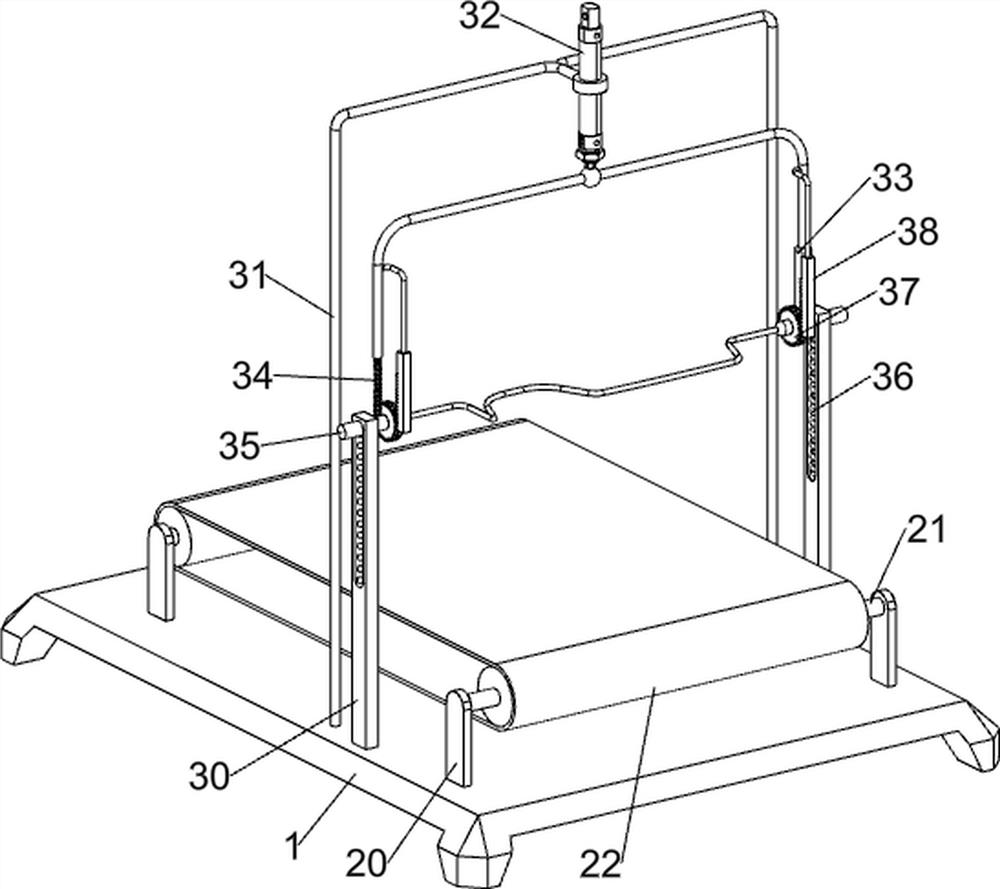

[0029] A styrofoam red wine glass placed packaging box hot-melt forming device, such as figure 1 and figure 2 As shown, it includes a base 1 , a storage mechanism 2 and a hot-melt mechanism 3 , the base 1 is provided with a storage mechanism 2 , and the storage mechanism 2 is provided with a hot-melt mechanism 3 .

[0030] When people need to use this device, at first people place Styrofoam on holding mechanism 2, then just can start hot-melt mechanism 3, and then hot-melt mechanism 3 moves downwards, then waits for hot-melt mechanism 3 and Styrofoam When in contact, the hot-melt mechanism 3 rotates and then heat-melts the Styrofoam. After the forming is completed, people reset the hot-melt mechanism 3, and then take out the material scraped off when the Styrofoam is formed, so that it can be completed. In order to melt the styrofoam, when people don't need to use the device, just close the hot melt mechanism 3 and get final product.

[0031] The holding mechanism 2 include...

Embodiment 2

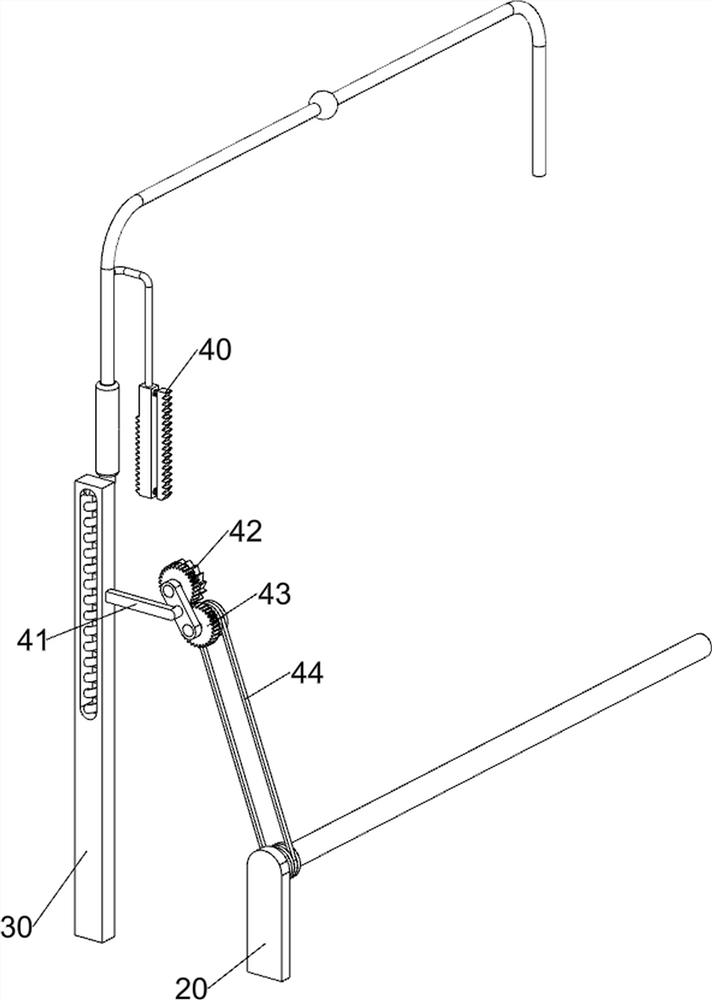

[0035] On the basis of Example 1, such as figure 1 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a moving mechanism 4 is also included. The moving mechanism 4 includes a ratchet 40, a second support frame 41, a ratchet 42, a second gear 43 and a first transmission assembly 44, and the rack 38 is provided with a ratchet 40 in a sliding manner. , an elastic member is provided between the ratchet 40 and the rack 38, the first slide rail 30 is provided with a second support frame 41, and the second support frame 41 is rotatably provided with a ratchet 42, and the ratchet 42 and the ratchet 40 Engagement, the second support frame 41 is equipped with a second gear 43 in a symmetrical rotation, the upper second gear 43 is connected with the ratchet 42, the two adjacent second gears 43 are engaged, and the lower second gear 43 is connected to one side. A first transmission assembly 44 is provided between the first rotating shafts 21 .

[0036] When the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com