Plasma arc cutting system based on oxygen-enriched process

A plasma arc and cutting system technology, applied in the field of ion arc cutting systems, can solve the problems of inability to meet high-quality cutting, residual metal liquid at the cutting port, and inability to blow away metal liquid, so as to improve cutting quality, improve cutting effect, The effect of fast airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

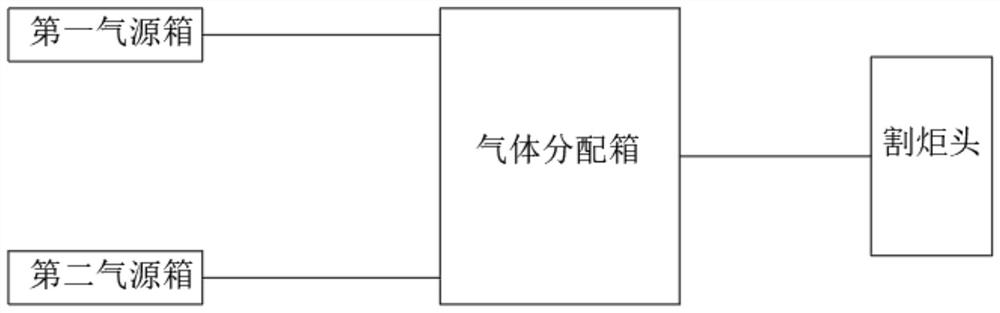

[0031] see figure 1 , The present invention provides a plasma arc cutting system based on an oxygen-enriched process. The plasma arc cutting system based on the oxygen-enriched process includes a cutting torch head, a first gas source box, a second gas source box and a gas distribution box, the cutting torch head communicates with the mixed gas outlet of the gas distribution box, the The first gas source box and the second gas source box communicate with the first gas inlet and the second gas inlet of the gas distribution box respectively.

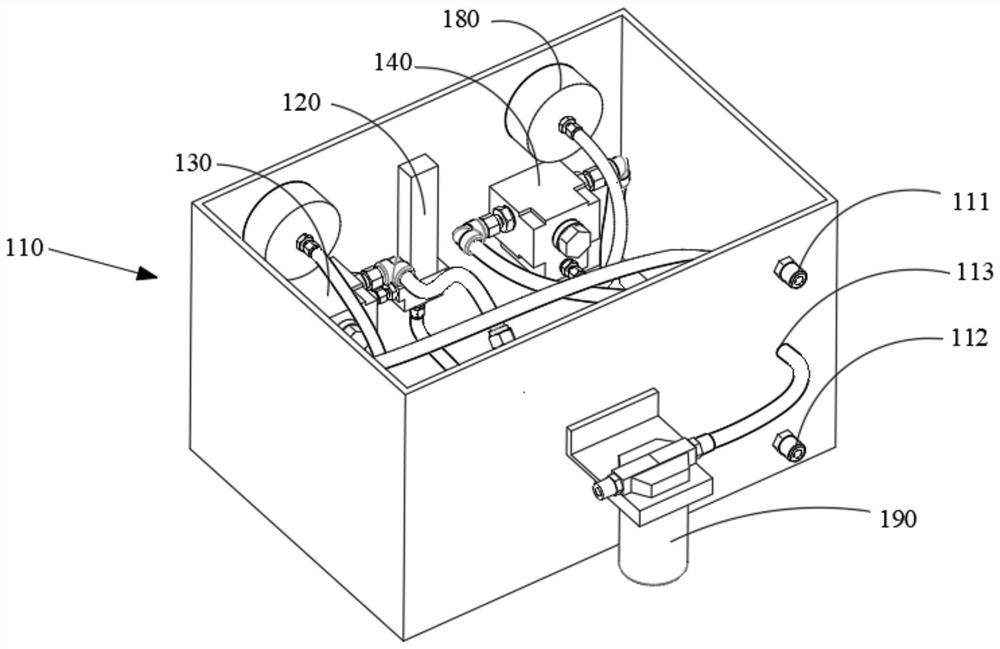

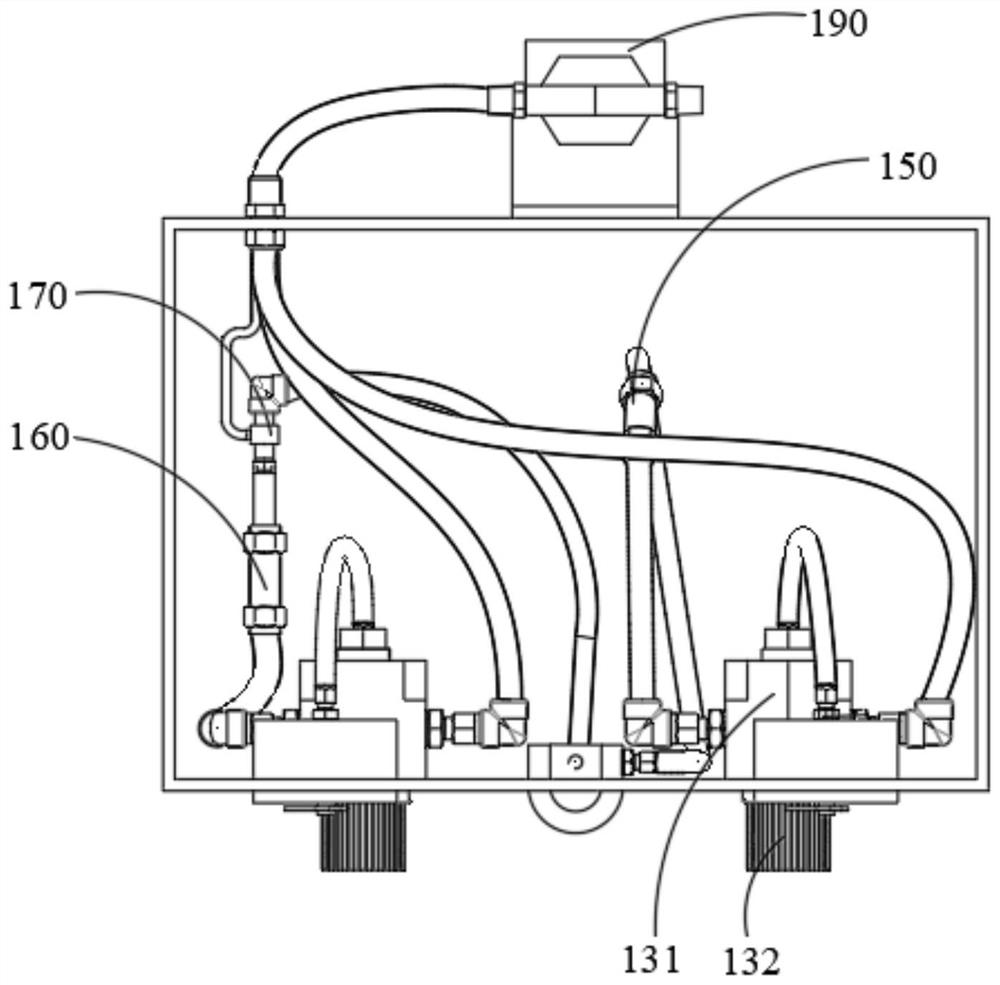

[0032] see Figure 2-Figure 4 , a gas distribution box, including a box body 110, a first gas inlet 111, a second gas inlet 112, a mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com