Novel beef paste packaging bottle cleaning and high-flow drying device

A drying device and packaging bottle technology, which is applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of affecting product cleaning effect, large water consumption, and packaging bottle damage, so as to improve uniformity and all-round performance, improve the contact surface, and ensure the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

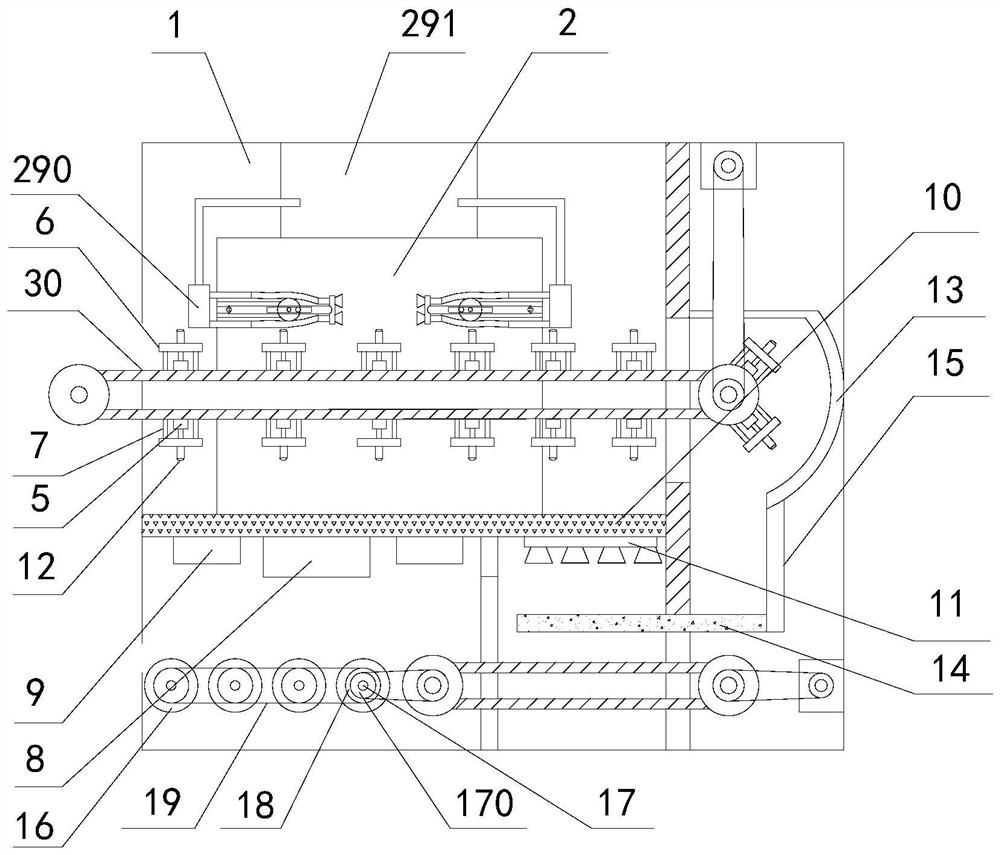

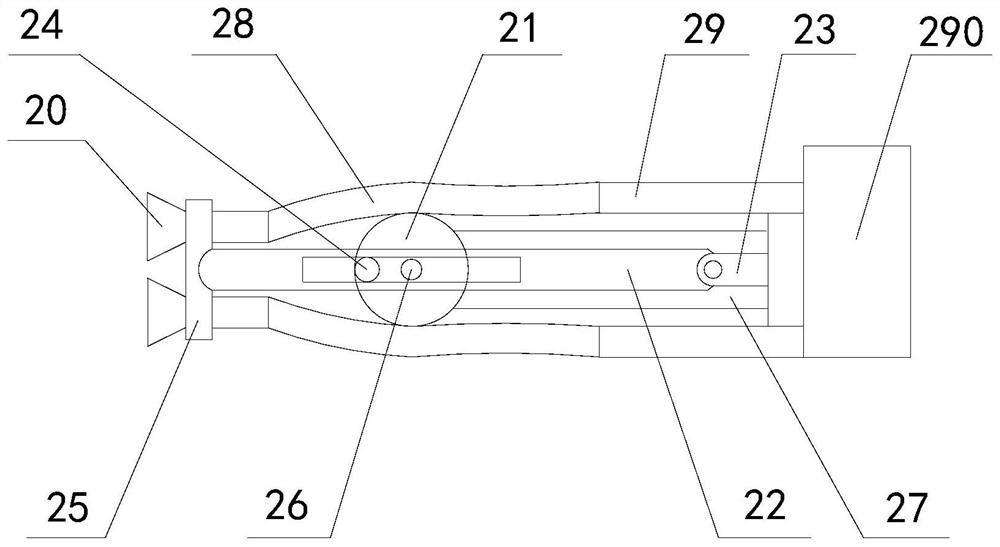

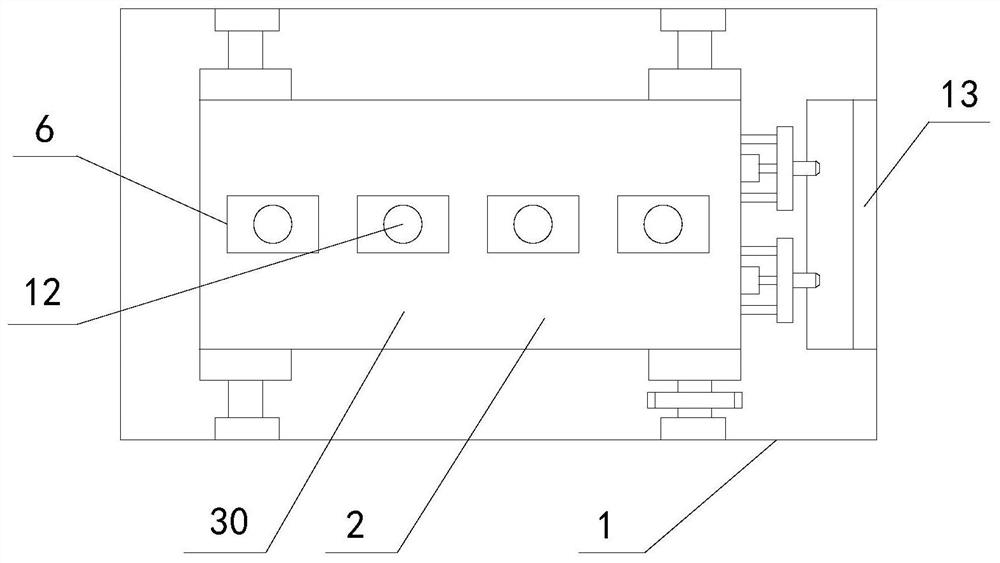

[0036]Such asFigure 1-5As shown, one embodiment of the present invention discloses a new type of beef sauce packaging bottle cleaning and strong current drying device, including a cleaning and drying box 1 and a first conveyor belt 30 for conveying the packaging bottles;

[0037]The cleaning and drying box 1 is provided with an outer wall cleaning chamber 2 for cleaning the outer wall of the beef sauce packaging bottle. One end of the first conveyor belt 30 is located outside the cleaning and drying box 1, and the other end of the first conveyor belt 3 passes through the cleaning and drying box in turn 1 The feeding door on one side and the cleaning chamber through the outer wall 2;

[0038]The cleaning and drying box 1 is provided with a second conveyor belt 31, the second conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com