Mycelium powder and production process thereof

A production process and technology of mycelium powder, applied in the field of mycelium powder and its production process, can solve problems such as low drying efficiency, and achieve the effects of improving procurement efficiency, speeding up drying efficiency, and convenient and unified use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] S1. Put the rice in a stainless steel basket, put it in a heating tank, wash it with cold water, wash away the sediment, etc., take out the basket and drain the dirty water;

[0028] S2. Fill the heating tank with water at a suitable position, heat the water in the heating tank to 90 degrees within ten minutes, put the rice in the basket in step 1 into the tank, soak and stir while soaking, until When the rice core is half-cooked, take out the basket quickly and put it into the fermentation box;

[0029] S3. After sealing the fermentation box, push it into the sterilization box for sterilizing at 127 degrees for 2 hours;

[0030] S4. Push the sterilized rice fermentation box into the strong cold room, and quickly cool down to about 30 degrees for standby;

[0031] S5. In a clean room equipped with an ultraviolet lamp, evenly sprinkle the Ganoderma lucidum seed liquid in the fermenter on the rice in the fermenter in step 4, stir and mix well, embed the sterilized temper...

Embodiment 2

[0036] S1. Pack the highland barley in a stainless steel basket, put it into a heating tank and wash it with cold water to remove the sediment, take out the basket and drain the dirty water;

[0037] S2. Fill the heating tank with water at a suitable position, heat the water in the heating tank to 100 degrees within ten minutes, put the highland barley in the basket in step 1 into the tank, soak, stir while soaking, until When the highland barley is half-cooked, the basket is quickly taken out and put into the fermentation tank;

[0038] S3. After sealing the fermentation box, push it into the sterilization box for sterilization at 127 degrees for 3 hours;

[0039] S4, push the sterilized highland barley fermentation box into the strong cold room, and quickly cool down to about 25 degrees for standby;

[0040] S5. In a clean room equipped with an ultraviolet lamp, evenly sprinkle the Antrodia camphorata seed liquid in the fermenter on the barley in the fermenter in step 4, st...

Embodiment 3

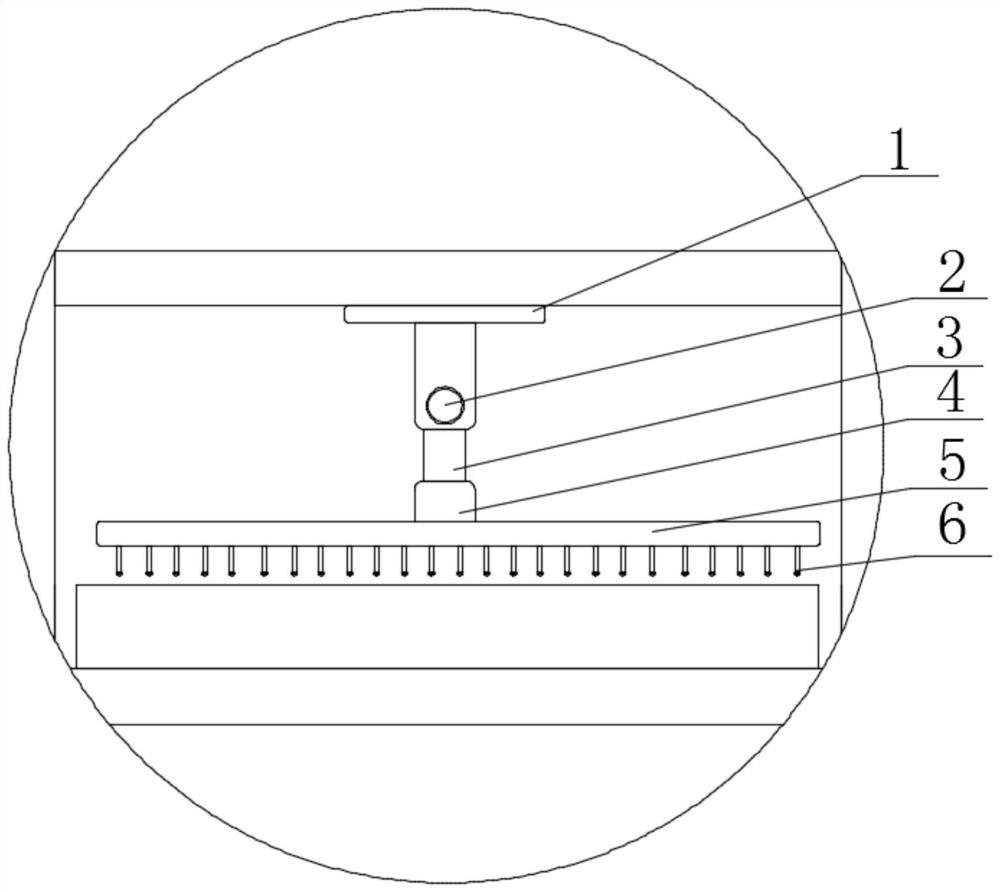

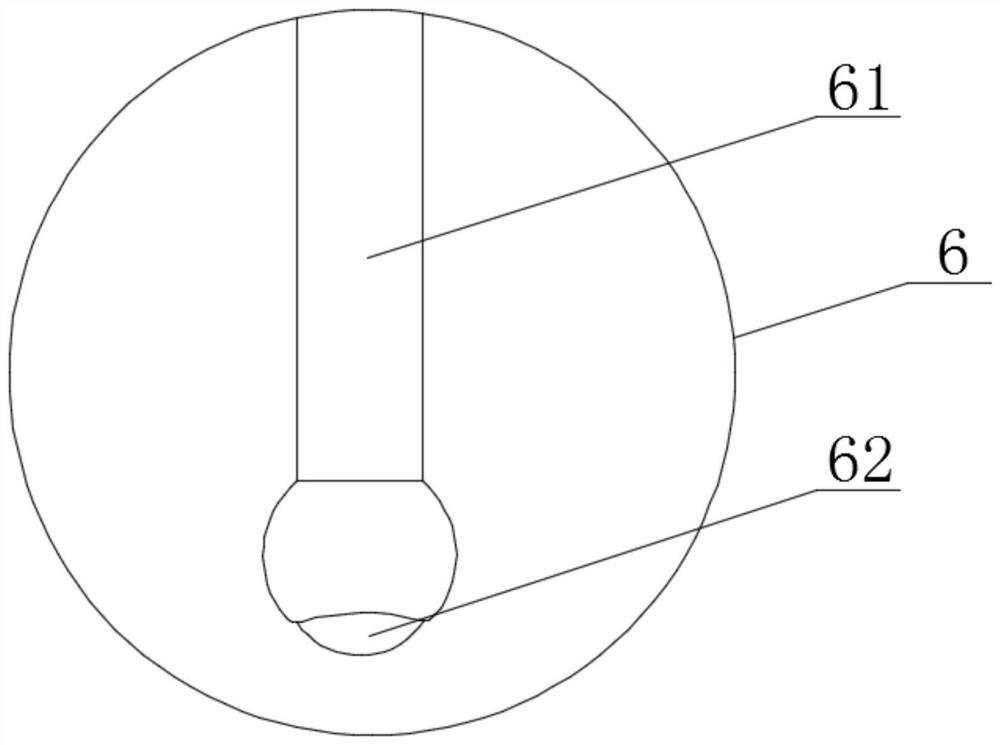

[0045] Such as Figure 1-2 As shown, a production process of mycelium powder includes the following steps: digging the cultivated mycelium, drying, crushing, and standby.

[0046] For specific implementation, when the mycelium is produced and processed, the mycelium is dried by a rotary drying box, and the mycelium is placed on a rotating frame inside the drying box through a tray, and the stirring auxiliary device is used for stirring and drying when rotating and drying. Dry, the telescopic mechanism 3 is fixed on the lower end of the clapboard fixed on the rotary frame in the dryer through the fixed plate 1, and the adjusting bolt 2 is loosened to make the telescopic mechanism 3 stretch out, driving the connected bearing seat 4 and the connecting plate 5 to Next, make the stirring mechanism 6 contact with the mycelium in the tray, when rotating, the rotating frame drives the tray with mycelium to rotate and dry, the telescopic mechanism 3 rotates with the rotating frame, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com