A flexible vibration mechanism for a berry plant fruit harvesting machine

A technology for fruit harvesting and operating machinery, which is applied to agricultural machinery and tools, agricultural machinery equipment, picking machines, etc. It can solve problems such as increasing costs, excessive heat generation, and loss of production, and achieves reduction of bevel tooth modulus, reduction of Production cost and the effect of reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

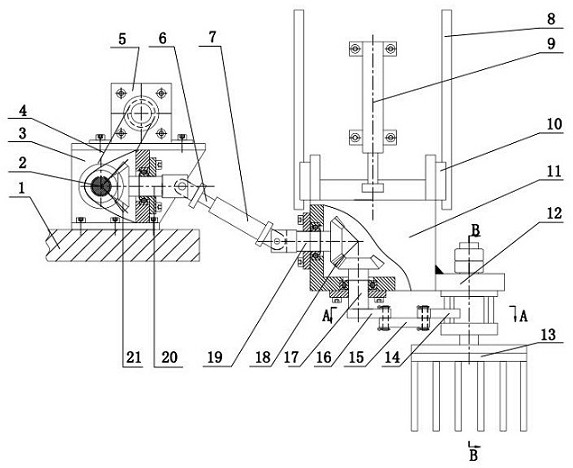

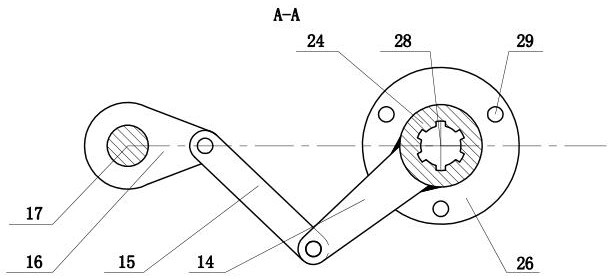

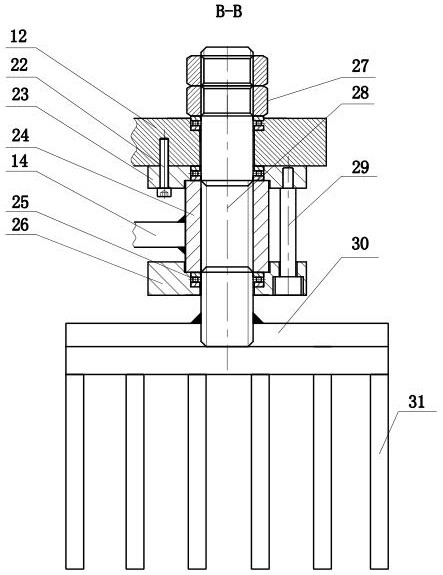

[0022] The embodiments of the present invention will be further described below in combination with the accompanying drawings.

[0023] The present invention includes a motor 5, a primary gear box 3, a secondary gear box 11, and a manipulator vibration plate assembly 13. The primary gear box 3 and the secondary gear box 11 are flexibly connected through a retractor, and the secondary gear box 11 and The manipulator vibrating plate assemblies 13 are connected by a link mechanism, the primary gear box 3 is fixed on the frame 1, and the secondary gear box 11 is a movable movable box.

[0024] The frame 1 is provided with a vertical rail 8 and a cylinder 9 , and a slider 10 that can slide on the vertical rail 8 is provided on the outer sides of both sides of the secondary gear box 11 . The seat body of the cylinder 9 is fixed on the frame 1 , and the cylinder rod of the cylinder 9 is connected with the upper side of the case body of the secondary gear box 11 . Pushed by the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com