Ultra-wideband millimeter-wave high-power planar film load

A millimeter-wave, high-power technology, applied in waveguide-type devices, electrical components, circuits, etc., can solve problems such as difficulty in meeting millimeter-wave high-power planar loads, patch loads being difficult to apply to millimeter-wave frequency bands, and increasing processing difficulty and cost. , to achieve the effect of improving the total power capacity, light weight and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

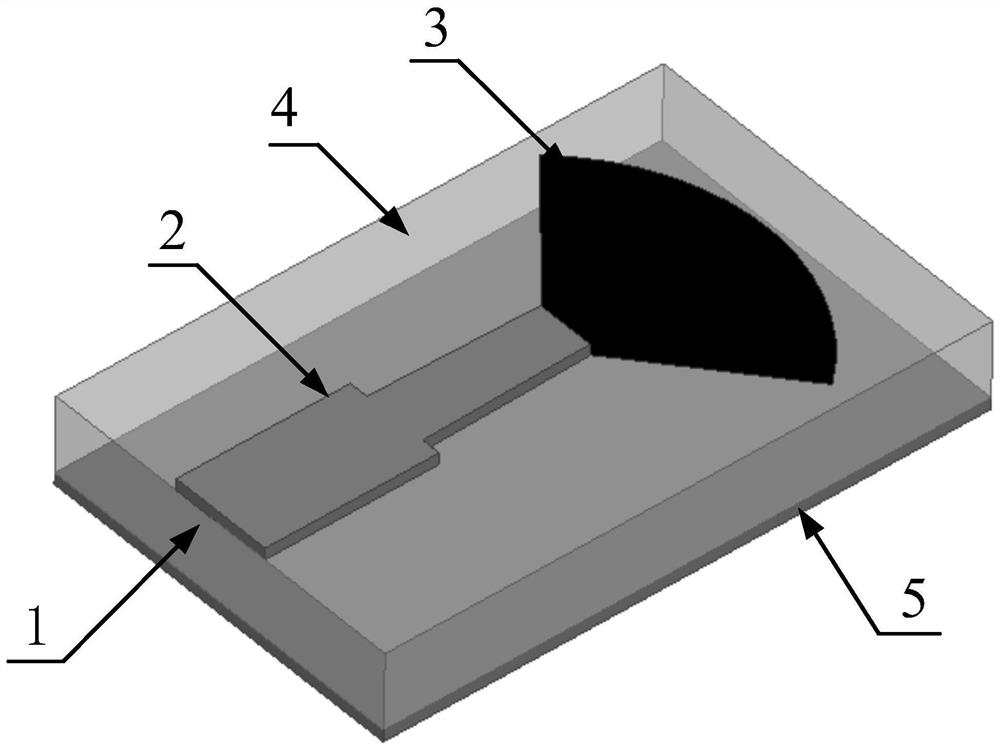

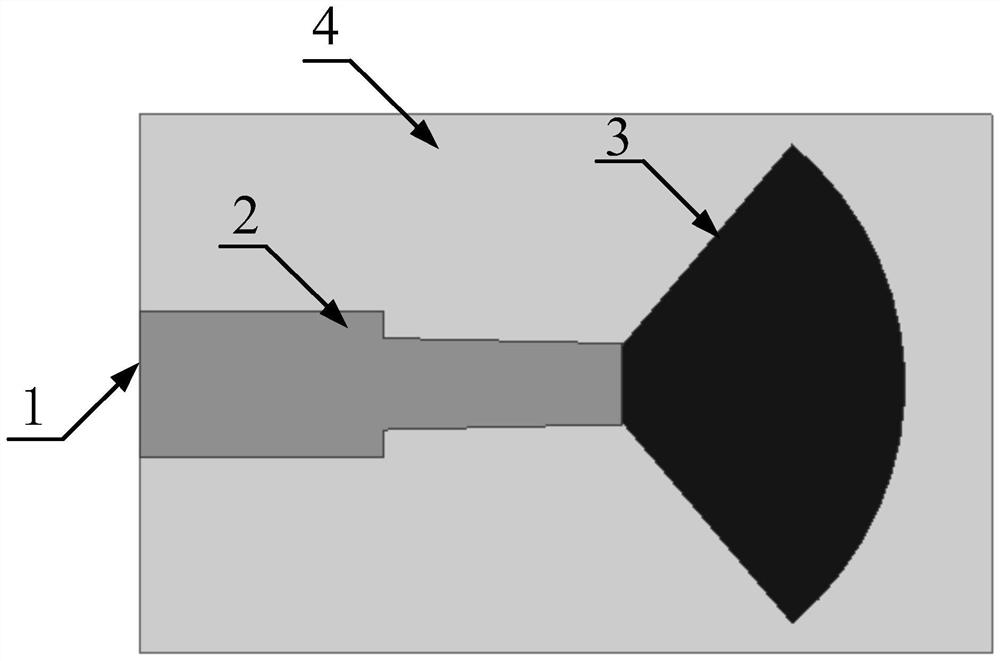

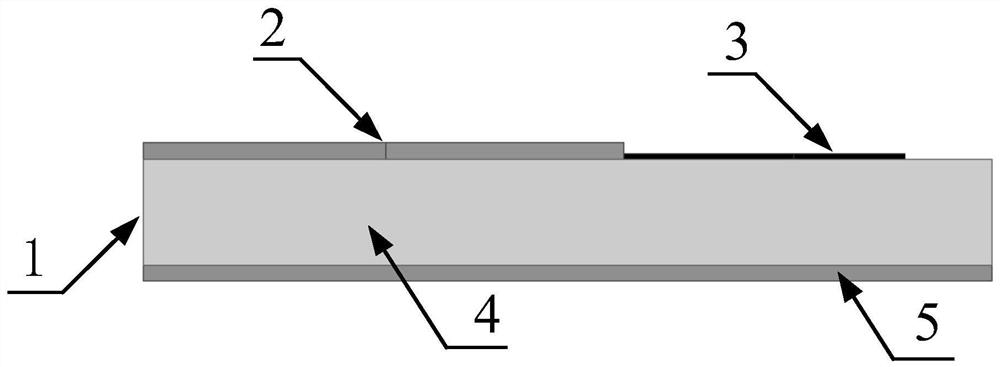

[0019] refer to Figure 1-Figure 3 . In the preferred embodiment described below, an ultra-wideband millimeter-wave high-power planar film load includes: a metal ground 5 arranged at the bottom of the dielectric substrate 4 and an input electrode 2 resistive film arranged on the dielectric substrate 4. One end is connected to the input The electrode 2 is connected and the other end is open in a fan-shaped structure. The input electrode 2 is connected to the fan-shaped resistive film through a microstrip impedance line, and a single-port thin film circuit is formed based on the fan-shaped resistive film. The radio frequency signal is fed from the input microstrip port 1 to the input electrode 2, through The microstrip impedance line enters the range of the sector-shaped resistive film, and guides the radio frequency signal to be transmitted from the end of the input electrode (2) to the open circuit end of the sector-shaped resistive film, so as to realize ultra-broadband match...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com