Filter stick stability evaluation method and microwave density detector

An evaluation method and density detection technology, applied in the direction of instruments, specific gravity measurement, measuring devices, etc., can solve the problems of unsuitable filter rod cutting characteristics, microwave density detector without shock absorbing device, and unable to reach the standard of constant temperature, etc., to achieve improvement The effect of service life and accurate detection data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

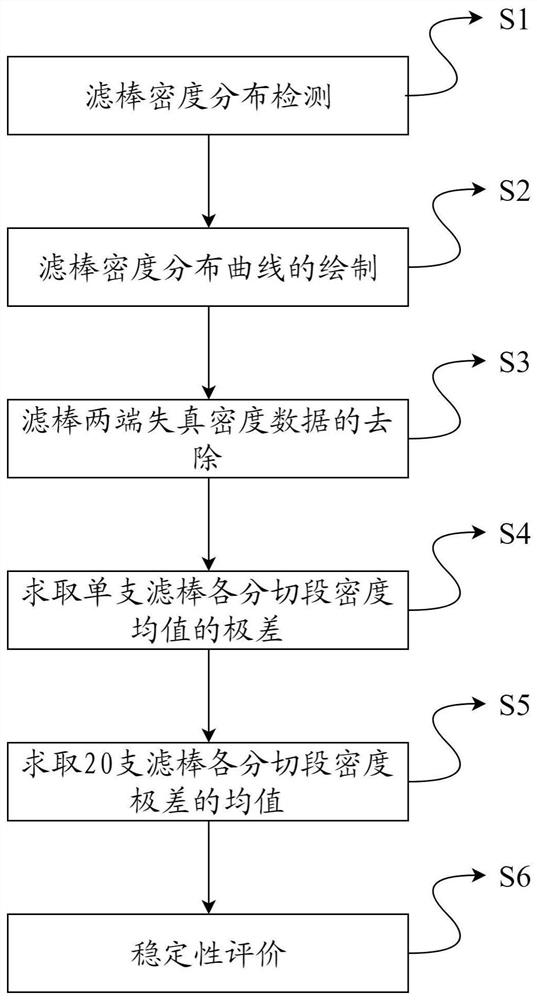

[0055] The present invention provides a technical solution: a filter rod stability evaluation method, comprising the following steps:

[0056] S1, detection of density distribution of filter rods, detecting the density of 20 filter rods by a density measuring instrument, and saving the density data;

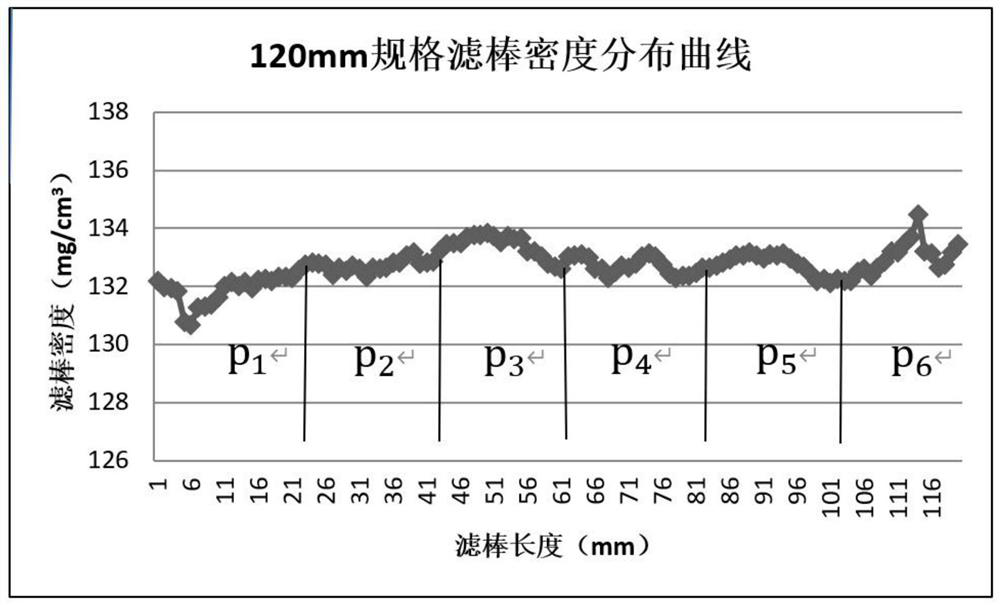

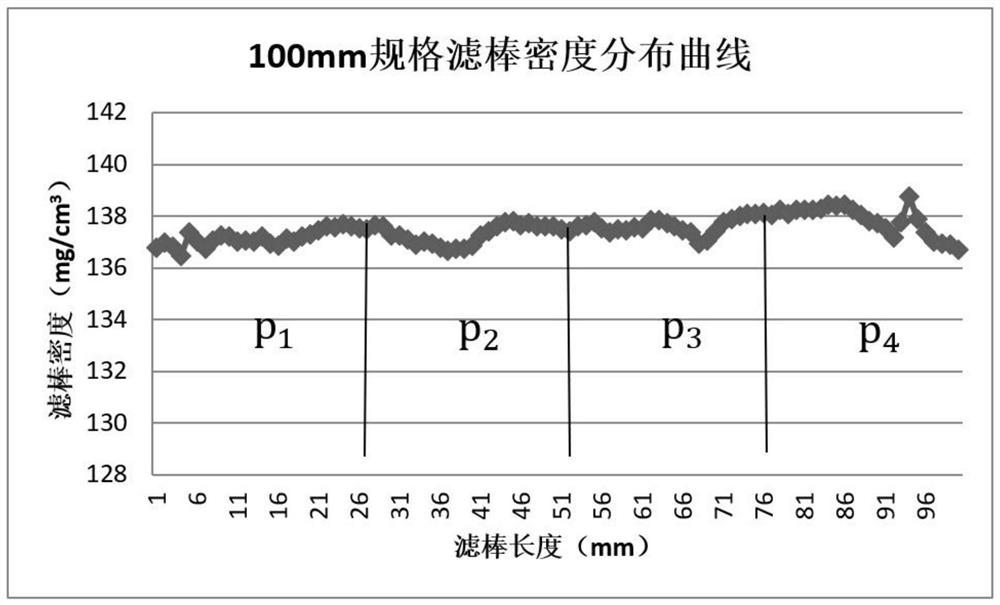

[0057] Specifically, 20 filter rods of two brands and specifications of 120 mm and 100 mm were randomly selected, and the density of the filter rods was detected by a microwave density detector, and the density data were saved.

[0058] S2, the drawing of the filter rod density distribution curve, according to the obtained filter rod density distribution data, the length of the filter rod is used as the abscissa, and the starting point of each section of the filter rod is used as the initial value of the abscissa, and each detection The filter rod density distribution data corresponding to the point is the ordinate, and the filter rod density distribution curve is made;

[0059]...

Embodiment 2

[0080] Refer to attached Figure 4-9 As shown, the present invention also provides a filter rod microwave density detector, comprising

[0081] Refer to attached Figure 4-8 As shown, the detection box 100 includes a box body 110, a feed port 120, a material distribution mechanism 130, a measuring drawer 140, a collection drawer 150 and a support foot 160, and one side of the box body 110 is provided with a feed port 120, and a material distribution mechanism 130 Set in the inside of the box body 110, the box body 110 is located at the bottom of the feed port 120 and is respectively provided with a measuring drawer 140 and a collection drawer 150, and one side of the measurement drawer 140 and the collection drawer 150 is fixedly connected with a handle 151, and the box body 110 A plurality of support feet 160 are installed at the bottom; filter rods enter through the feeding port 120, and are transported to the measuring drawer 140 one by one by the material distributing mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com