Material bending durability testing device

A testing device and durability technology, applied in the direction of measuring devices, analyzing materials, and testing the strength of materials by applying repetitive force/pulsation force, etc., can solve the problems of uniformity of results, lack of special testing equipment for bending durability, etc. The effect of saving test time, simple structure and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

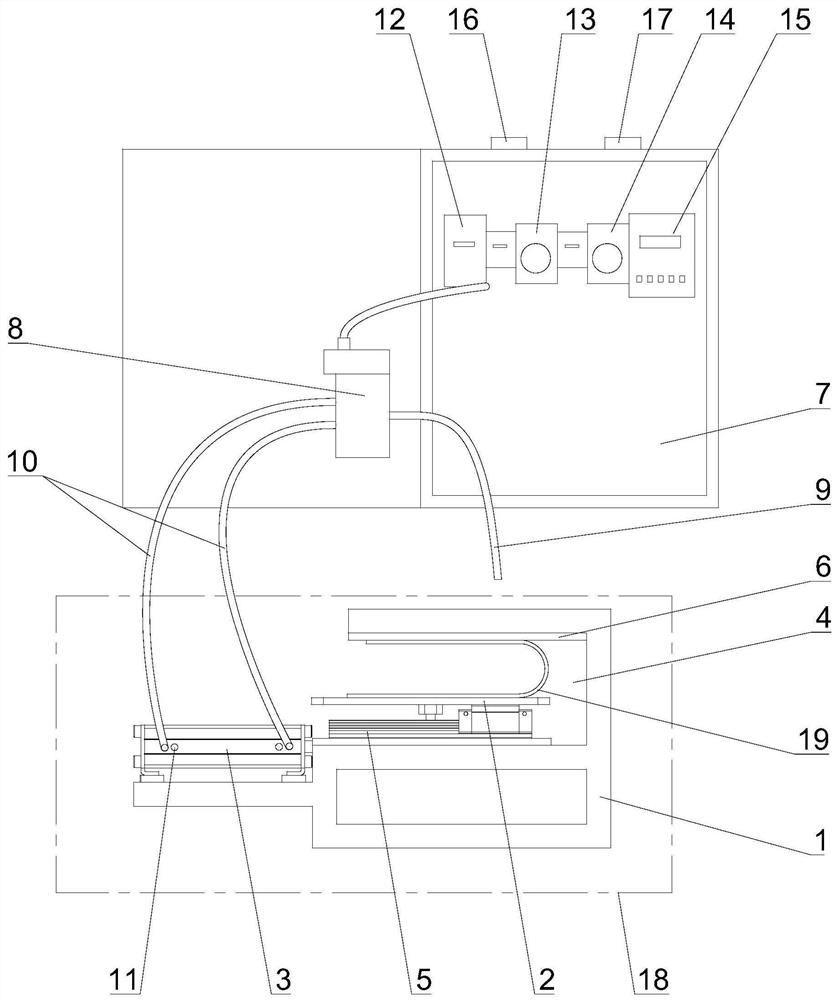

[0012] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0013] see figure 1 As shown, this embodiment provides a material bending durability test device, which includes a test tool and a control box 7 .

[0014] The test tooling includes a tooling frame 1, a bracket slide 2 and an action cylinder 3. A cavity 4 is set in the tooling frame 1, a guide rail 5 is set at the bottom of the cavity 4, a friction layer 6 is set at the top of the cavity 4, and the action cylinder 3 The drive bracket slide table 2 slides on the guide rail 5 .

[0015] The sample 19 to be tested is placed in the cavity 4 in a curved manner, and one end of it is fixed on the bracket slide 2, and the other end is in static friction contact with the friction layer 6. The action cylinder 3 is driven by the control box 7 to drive the bracket slide 2 to reciprocate , so as to carry out t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com