Vertical-axis wind turbine blade and structure thereof

A technology of wind power generators and vertical shafts, applied in wind power generators, wind power generators at right angles to the wind direction, engines, etc., can solve problems affecting the service life of wind shafts, affecting power generation efficiency, wind shaft breakage, etc., and achieve wind energy utilization High, compact and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

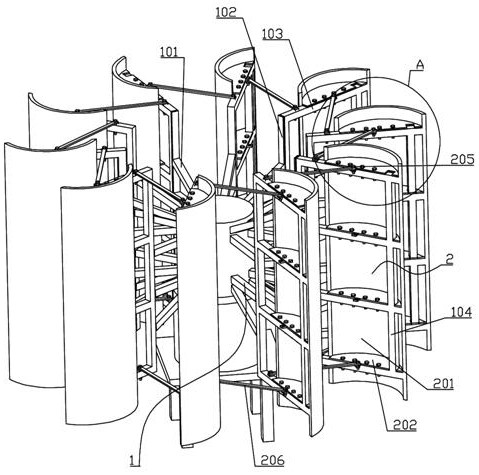

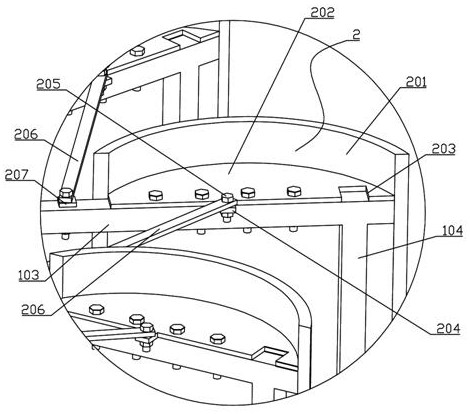

[0020] like figure 1 , figure 2 As shown, a vertical axis wind turbine blade and its structure of the present invention include a ceramic aluminum alloy support 1 that is rotatably connected to the upper end of the wind shaft. The ceramic aluminum alloy support 1 includes several support frames 101 and a first side support 102 , several support frames 101 are connected in a trapezoidal shape as a whole, one end of several support frames 101 is connected to the upper end of the wind shaft, and the other end is connected to the first side support 102, and the first side support 102 is connected to four horizontal supports 103, and several horizontal supports 103 are combined The second side bracket 104 is connected, the horizontal bracket 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com