A composite lining structure of corrugated steel plate and steel truss for tunnel

A technology of corrugated steel plate and steel truss, which is applied in the direction of tunnel lining, tunnel lining, shaft lining, etc., can solve the problems of insufficient light weight and rapid assembly construction of steel structure, poor economy of reinforced concrete secondary lining structure, and large proportion of lining structure, etc. Achieve the effect of reducing post-operation and maintenance costs, improving self-waterproof ability, and light weight of a single block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

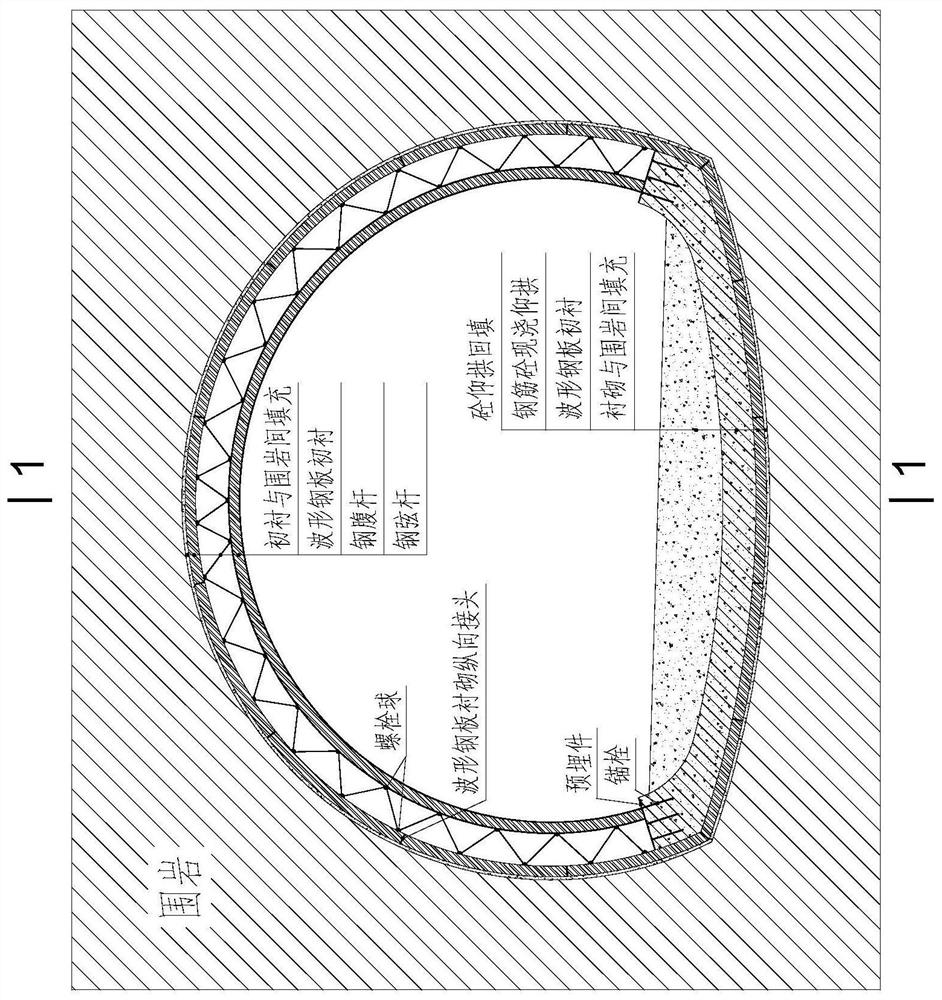

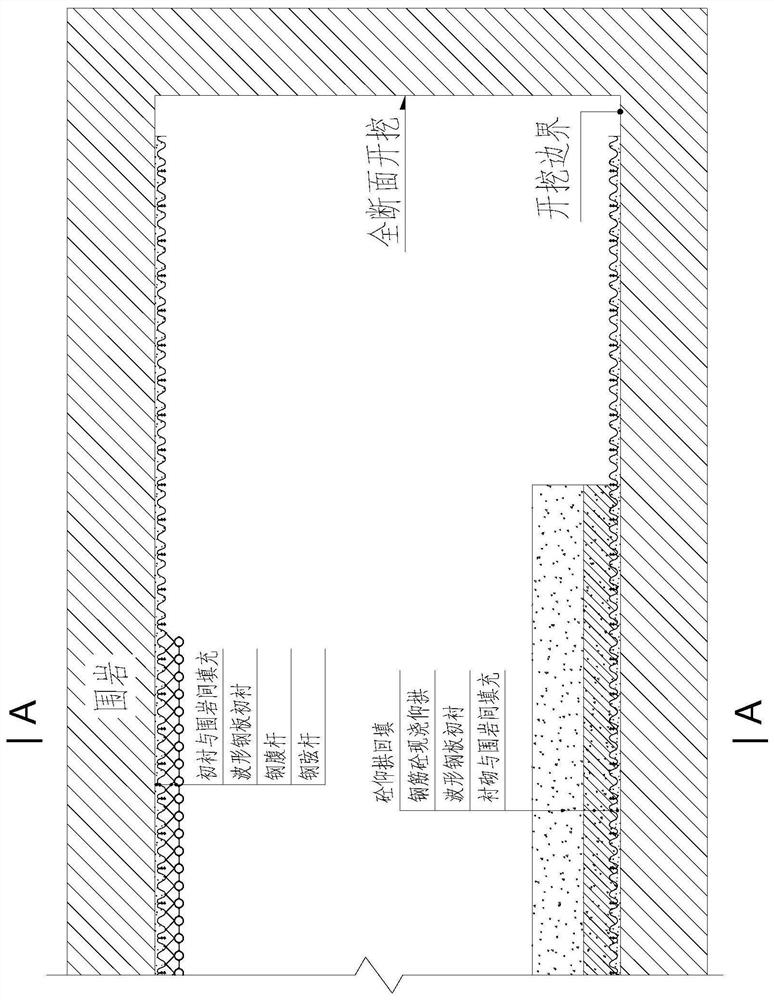

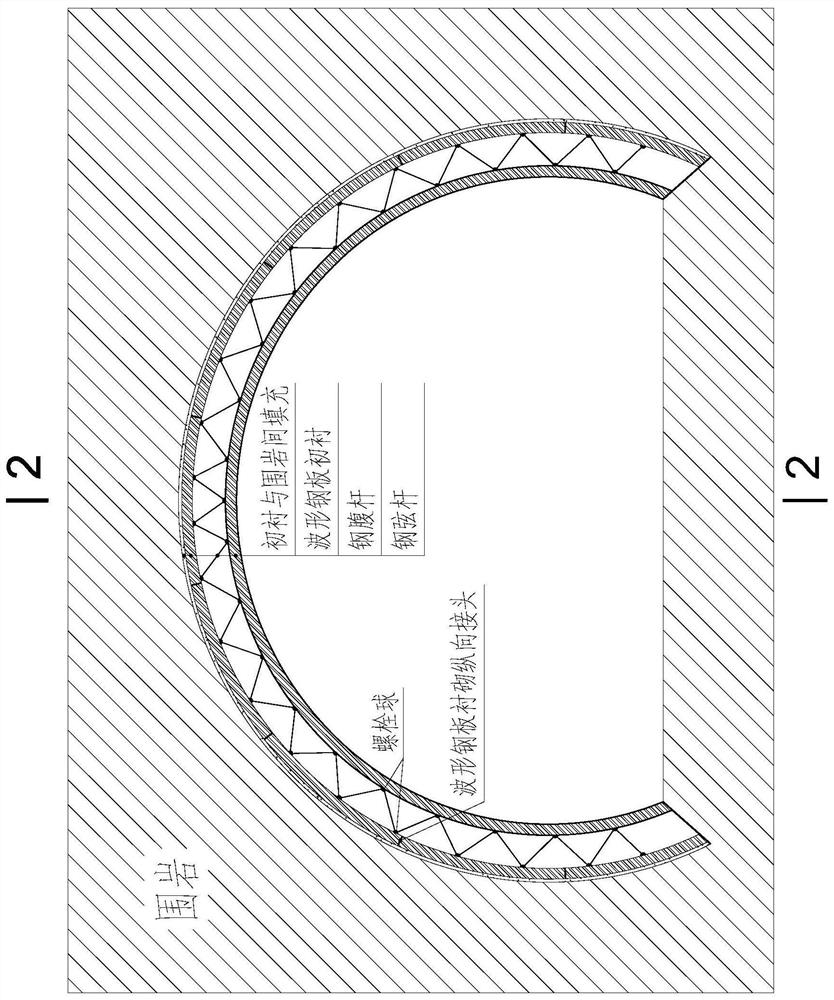

[0038] like Figure 1-7 As shown, the present invention provides a corrugated steel plate and steel truss combined lining structure for tunnels, the combined lining structure includes a corrugated steel plate primary lining and a steel truss fixed on the inner side of the corrugated steel plate lining as a secondary lining, and the corrugated steel plate initial lining is prefabricated by multiple pieces The corrugated steel plates are assembled and formed by longitudinal joints and circumferential joints in the circumferential and longitudinal directions, respectively. The corrugated steel plates are provided with steel plate grooves at the longitudinal joints and the circumferential joints respectively, and pass through the steel plate grooves of adjacent corrugated steel plates. Glue and press the water stop gasket to achieve a watertight seal.

[0039] The annular joint includes a circular arc flange integrally formed with the edge of the corrugated steel plate perpendicul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com