Open type absorption heat pump sludge drying system and using method

An absorption heat pump, sludge drying technology, applied in heat pump, dewatering/drying/concentrating sludge treatment, refrigeration and liquefaction, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

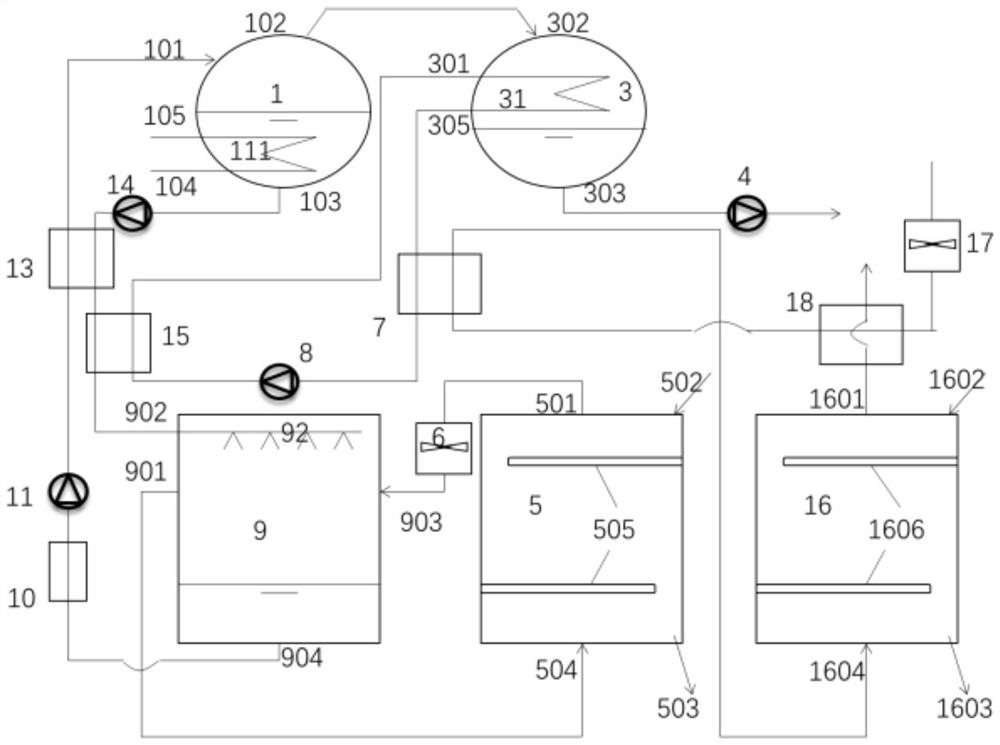

[0077] An open absorption heat pump sludge drying system, such as figure 1 Shown is a single-effect structure of an open absorption heat pump sludge drying system, including a condensing device and an open absorber 9, a first drier 5, and a second drier 16, all of which are hollow structures. It also includes a first heat exchanger 13, a third heat exchanger 15, a first air heat exchanger 7 and a second air heat exchanger 18 each having a heating channel and a cooling channel, and the heating channel and the cooling channel are isolated from each other And they are all made of high-efficiency heat exchange materials. The temperature of the liquid or gas flowing through each heating channel is lowered, and the temperature of the liquid or gas flowing through each cooling channel is increased, thereby realizing the cooling of the liquid or gas in the heating channel. The purpose of the liquid or gas in the channel exchanging heat with each other; to simplify the description, all...

Embodiment 2

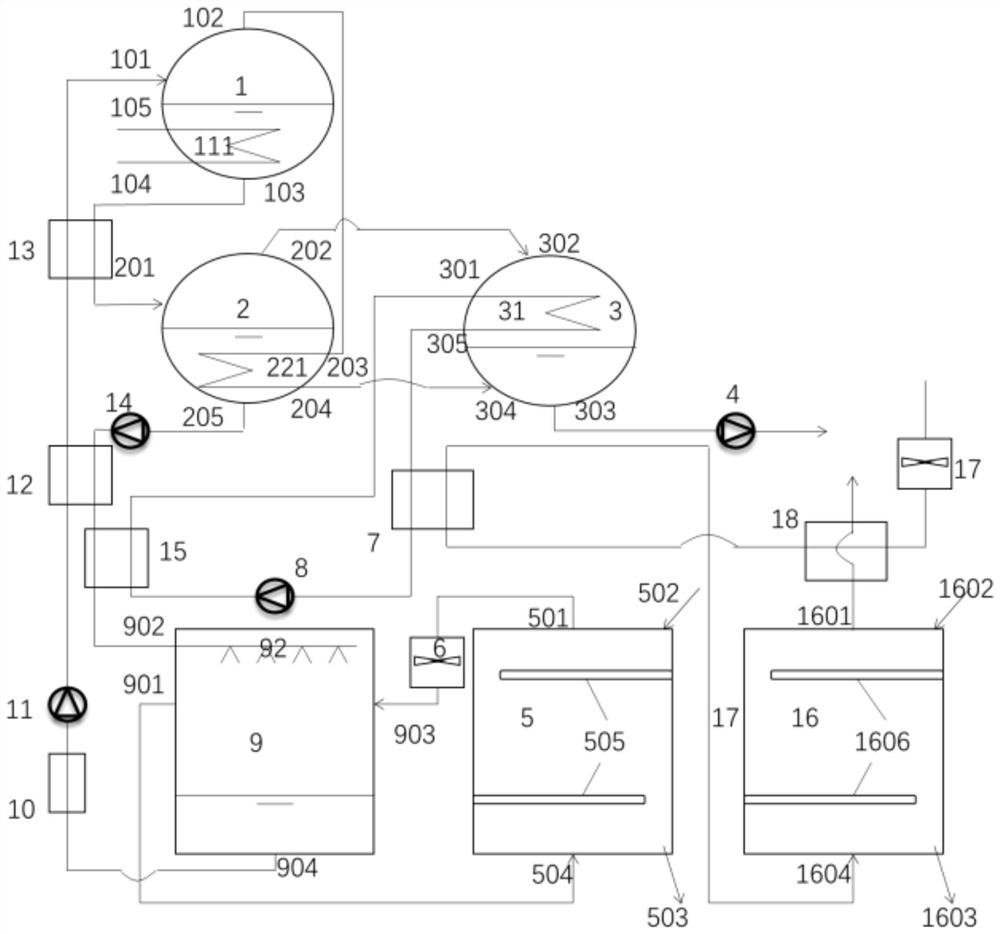

[0110] An open absorption heat pump sludge drying system, such as figure 2 Shown is a double-effect structure of an open absorption heat pump sludge drying system, and the following changes are made on the basis of Example 1:

[0111] 1. The condensing device increases the second generator 2 and the second heat exchanger 12 on the basis of embodiment 1, and becomes a double-effect evaporation structure;

[0112] 2. Remove the connection between the steam outlet 102 of the first generator and the steam inlet 302 of the condenser;

[0113] 3. On the wall of the condenser 3, a condenser condensate inlet 304 communicating with the inner cavity of the condenser 3 is added;

[0114] 4. The solution circulation pipeline a is correspondingly adjusted to the solution circulation pipeline c.

[0115] details as follows:

[0116] The condensing device also includes a hollow second generator 2 with a sealed structure. The inside of the second generator 2 is provided with a hollow and ...

Embodiment 1

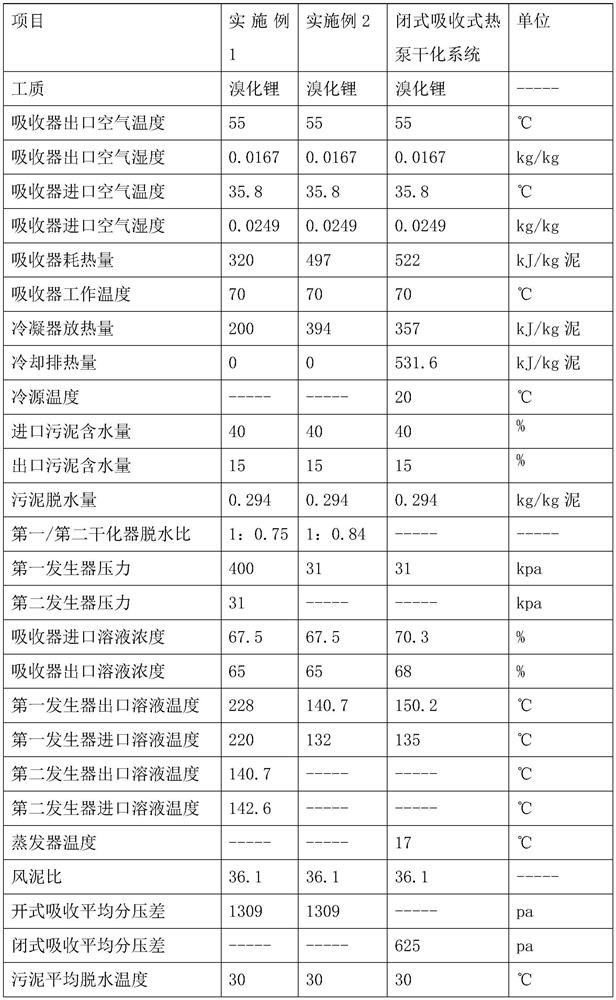

[0143]The design conditions of implementation example 1 are: the initial water content of sludge is 40%, the water content after dehydration is 15%, the average dehydration temperature is 30°C, the working temperature of the absorber is 70°C, the air-to-solid ratio is 36.1:1, and the dry hot air temperature is 55 ℃, the moisture content is 0.0167kg / kg. The calculation parameters of implementation example 1 are shown in Table 1 (for 1kg sludge). Compared with implementation example 2, implementation example 1 adopts a single-effect structure, although the water production ratio (i.e. heat utilization efficiency, defined as the ratio of dehydration evaporation latent heat to heat consumption) ratio) is reduced from 2.13 in Example 2 to 1.45, but its benefit is that compared with Example 2, one generator is reduced, the system is simplified, and the heat source temperature requirement is reduced from 228°C to 140.7°C, and the adaptability to the heat source is better Strong, comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com