Method for intensively collecting, treating and recycling construction wastewater in dam area of hydropower engineering in high mountain and valley area

A technology for hydropower engineering and waste water, which is applied in water/sewage treatment, neutralized water/sewage treatment, water/sewage treatment equipment, etc. It can solve the problems of difficult collection and treatment of construction waste water, river water pollution, etc., and achieve the solution of waste water treatment cost-prohibitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Embodiment 1: The present invention is respectively applied to the centralized collection, treatment and reuse of construction wastewater during the construction period of a diversion tunnel of a hydropower project;

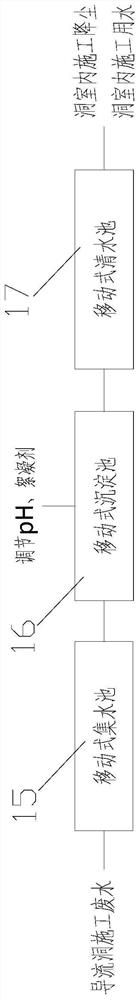

[0070] Such as figure 1 As shown, this embodiment is a method for centralized collection, treatment and reuse of construction wastewater in a hydropower project dam area, which specifically includes the following steps:

[0071] During the construction period of the diversion tunnel of the hydropower project, according to the segmented construction plan of the diversion tunnel, first set up in the construction section of the diversion tunnel 1# figure 1 The included facilities include mobile water collection tank 15, mobile sedimentation tank 16 and mobile clean water tank 17, and mobile water collection tank 15, mobile sedimentation tank 16 and mobile clean water tank 17 are connected by steel plate welding; #The size of the tunnel flow section in the co...

Embodiment 2

[0075] Embodiment 2: The present invention is respectively applied to the centralized collection, treatment and reuse of construction wastewater in the upstream cofferdam and downstream cofferdam construction of a certain hydropower project;

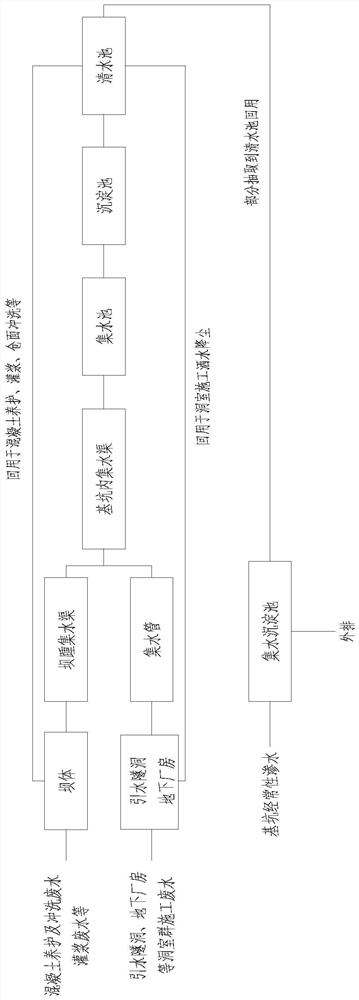

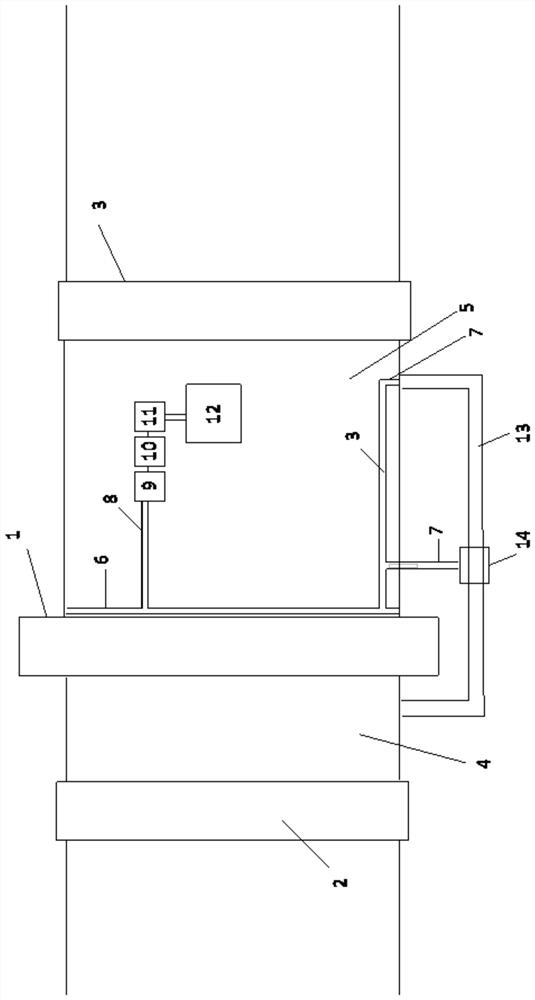

[0076] Such as figure 2 , image 3 As shown, this embodiment is a method for centralized collection, treatment and reuse of construction wastewater in a hydropower project dam area, which specifically includes the following steps:

[0077] During the construction of the upstream cofferdam and the downstream cofferdam of the hydropower project, a sump 9, a sedimentation tank 10, and a clear water pool 11 are set in the area between the highest point and the lowest point within the downstream foundation pit, and the elevation of the downstream foundation pit 5 is 2100 ~2115m, the water collection tank 9, the sedimentation tank 10, and the clean water tank 11 are set in the downstream foundation pit 5 at an elevation of about 2105~2110m; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com