An airport autonomous mobile robot, baggage and cargo transfer system, and method of use

An autonomous mobile, robotic technology, applied in the direction of motor vehicles, conveyor objects, mechanical conveyors, etc., can solve the problems of waste of resources, flight delays, easy to misclassify, etc., to reduce energy consumption, save construction costs, improve The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

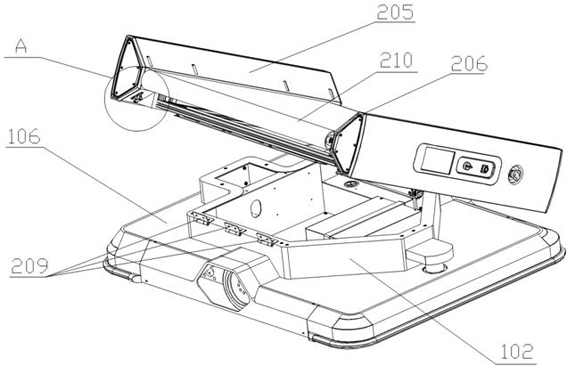

[0052] refer to Figure 2-Figure 10 As shown, an airport autonomous mobile robot provided by the present invention includes an upper transfer device, an RFID reader, a signal receiver and a chassis, the upper transfer device is connected to the chassis through a hinge 209, and the RFID reader is used to confirm the goods or baggage information, the signal receiver is used to receive external signals;

[0053] The upper transfer device comprises a front baffle 205, a back baffle 206, and a conveying device, and the conveying device is installed between the front baffle 205 and the rear baffle 206, and the upper surfaces of the front baffle 205 and the rear baffle 206 are all provided with The photoelectric sensor 207, the bottom surface of the front baffle 205 is provided with a removable female terminal installation hole 307, and a removable terminal is fixed in the removable female terminal installation hole 307; the removable terminal includes a removable female terminal 301...

Embodiment 2

[0058] refer to Figure 4-Figure 7 As shown, further optimization is made on the basis of Embodiment 1: the transmission device includes a power roller 201, a non-power roller 204 and a belt 210, and the power roller 201 and the non-power roller 204 are connected to the front through a roller bracket 208 and a support plate 203. The inner side of the baffle plate 205 and the rear baffle plate 206, and the belt 210 are sleeved on the cylindrical surfaces of the power drum 201 and the non-power drum 204, and the power drum 201 is an electric drum with its own power.

[0059] The goods are transferred from the importing conveyor line to the belt 210, and are carried out through the photoelectric sensor 207 on the upper transfer device, and the driving power roller 201 is driven to drive the belt to adjust the position. After the autonomous mobile robot moves to the specified place, the driving power roller 201 is driven again It rotates, and the luggage or cargo is driven by the ...

Embodiment 3

[0061] refer to Figure 4 As shown, further optimization is made on the basis of Embodiment 1: the chassis stabilizing frame 106 is also provided with auxiliary traveling wheels 107, and the auxiliary traveling wheels 107 are installed on the bottom of the chassis stabilizing frame 106, between the driving wheels 108, Adding auxiliary walking wheels 107 is used for stabilizing the chassis and avoiding situations such as shaking during the walking process of the autonomous mobile robot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com