Wet type dust clearing device capable of automatically adding water for stone engraving machine

A technology for automatically adding water and cleaning devices, which is applied in the fields of engraving, decorative art, and processing models, etc. It can solve problems such as increasing costs, affecting device practicability, and wasting resources, so as to prevent dust from flying, improve device flexibility, and save water resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

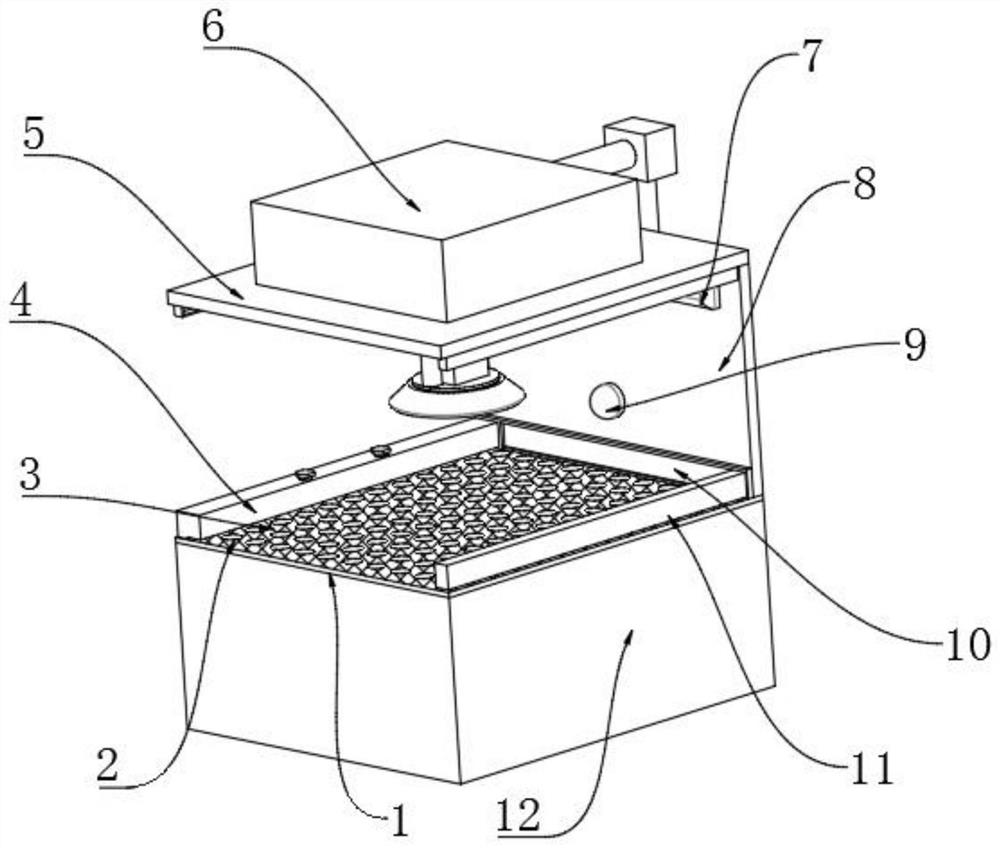

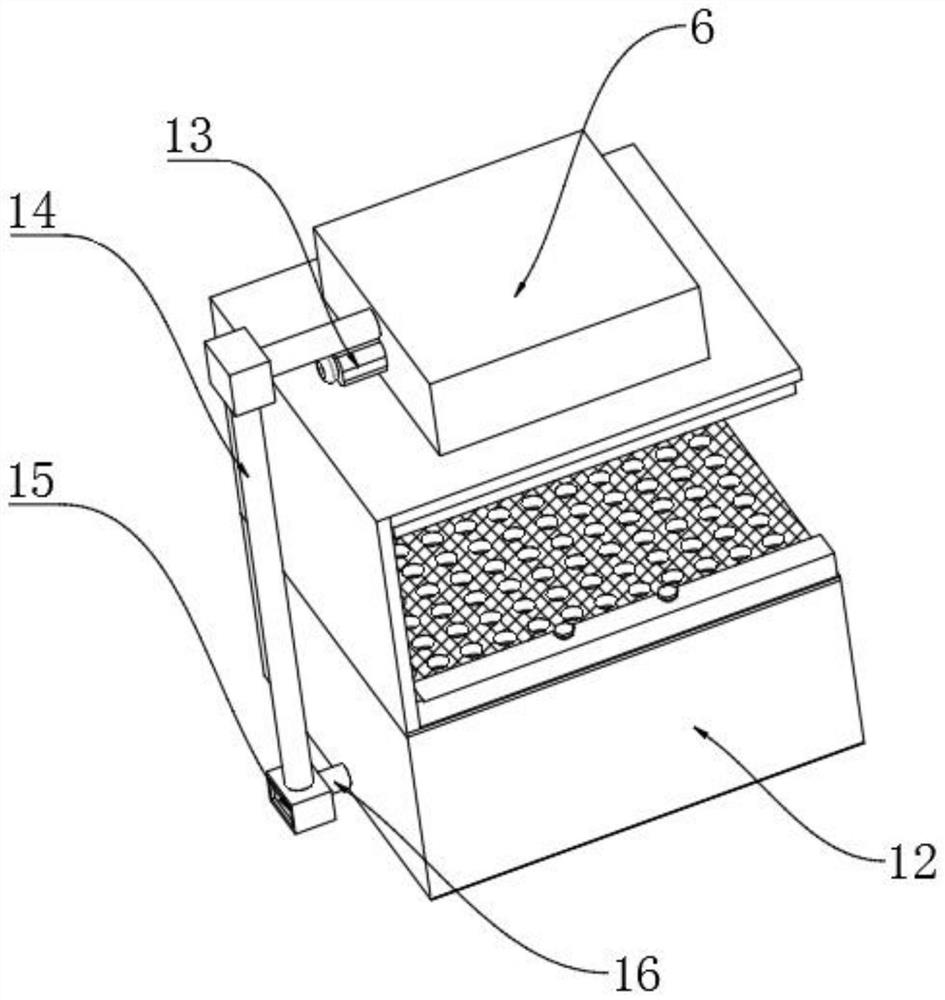

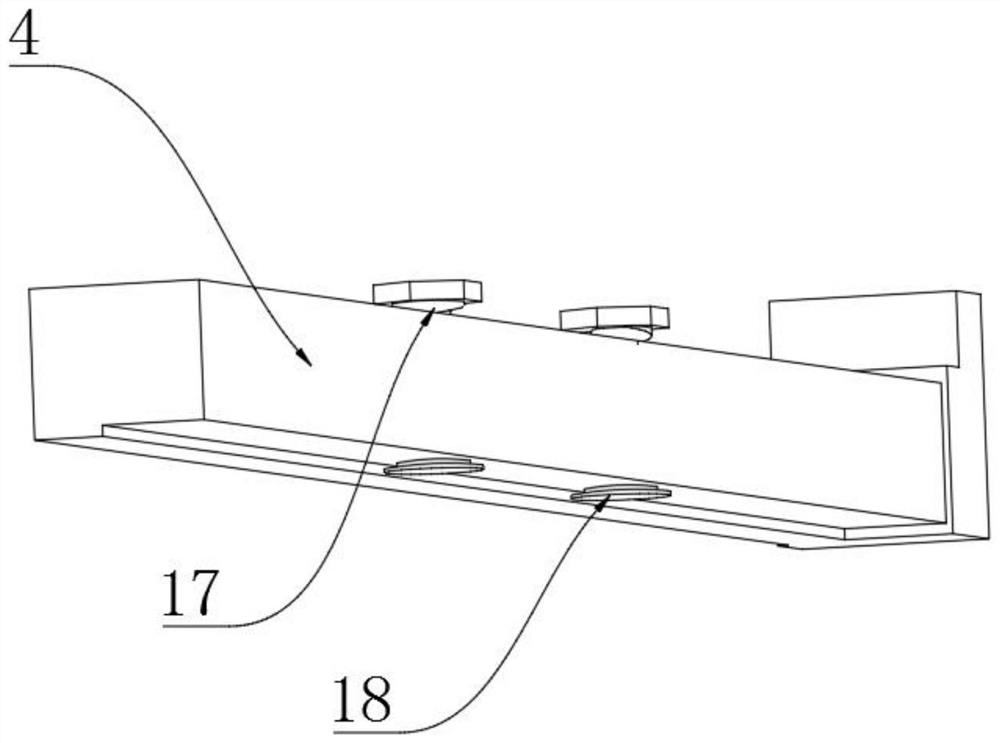

[0035]A wet dust cleaning device that can automatically add water for a stone engraving machine, such as figure 1 , figure 2 , Figure 8 As shown, it includes a workbench 1; the inner wall of one side of the workbench 1 is processed with evenly distributed filter holes 2; the top outer wall of the workbench 1 is placed with gauze 3; the outer wall of the bottom end of the workbench 1 is fixedly connected with a waste water tank 12 The outer wall at the top of the waste water tank 12 is fixedly connected with the bearing plate 8 by screws; the outer wall at the top of the bearing plate 8 is fixedly connected with the top plate 5; the outer wall at the top of the top plate 5 is fixedly connected with the water storage tank 6 by screws; the outer wall of the water storage tank 6 is connected by bolts There is a suction pipe 14; the outer wall of one side of the suction pipe 14 is connected with a suction pump 13 by bolts; the outer wall of the bottom end of the suction pipe 14 ...

Embodiment 2

[0043] A wet dust cleaning device that can automatically add water for a stone engraving machine. In order to disinfect the recycled water and speed up the disinfection, such as Figure 7 , Figure 8 As shown, this embodiment makes the following improvements on the basis of Embodiment 1: the inner wall of one side of the waste water tank 12 is fixedly connected with an array of electric heating tubes 32; the number of electric heating tubes 32 is more than two; the waste water tank 12. The inner wall on one side is fixedly connected with a liquid level sensor 33 by screws; the electric heating tube 32 and the liquid level sensor 33 are electrically connected to the internal control unit; 33 can detect the liquid level of recovered water inside the waste water tank 12 in real time. When the liquid level of recovered water does not reach the level of submerging the electric heating tube 32, the electric heating tube 32 will not operate, preventing the electric heating tube 32 fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com