Magnesium-alloy thermotherapy nano robot and preparation method therefor

A nano-robot, magnesium alloy technology, applied in the nano field, can solve the problems of local inflammatory response, unstable production process, difficult to control degradation time, etc., to achieve the effect of relieving inflammatory response, stable production process and suitable for industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

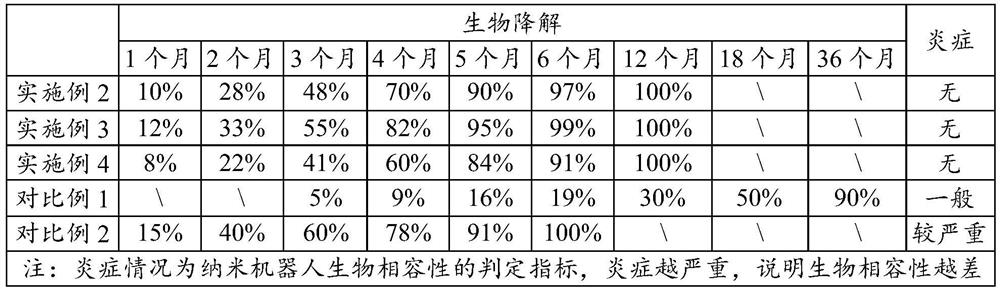

Examples

preparation example Construction

[0022] The invention provides a method for preparing a magnesium alloy hyperthermia nanorobot, comprising the following steps:

[0023] a) performing solid solution treatment on the magnetic magnesium alloy to obtain a magnetic magnesium alloy melt;

[0024] b) adding the magnetic magnesium alloy melt dropwise into a cold bath under stirring conditions to obtain magnetic magnesium alloy nanoparticles;

[0025] c) mixing the magnetic magnesium alloy nanoparticles and anti-inflammatory drugs in a solvent, centrifuging, and discarding the supernatant to obtain a magnesium alloy nanorobot.

[0026] In the preparation method provided by the present invention, the magnetic magnesium alloy is firstly subjected to solution treatment. Wherein, the chemical composition of the magnetic magnesium alloy preferably includes Nd, Zn, Zr, Fe, Si, Mn and Mg, more preferably includes 4wt% of Nd, 16wt% of Zn, 14-19wt% of Zr, 1wt% of Fe , 0.3wt% of Si, 1wt% of Mn and 55-61wt% of Mg. In an embod...

Embodiment 1

[0036] Preparation of Magnetic Magnesium Alloy Nanoparticles:

[0037] 1) The magnetic magnesium alloy is subjected to solution treatment at 750° C. for 7.5 hours to obtain a magnetic magnesium alloy melt. Wherein, the chemical composition of the magnetic magnesium alloy is: Nd 4wt%, Zn 16wt%, Zr 14-19%, Fe 1wt%, Si 0.3%, Mn 1wt%, and the balance of Mg.

[0038] 2) Add the magnetic magnesium alloy melt dropwise into a -72°C dry ice ethanol bath under stirring conditions. During the dropping process, the dropping rate is controlled at 1-5mL / min, the dropping time is controlled at 10min, and the stirring rate is Control it at 30-50r / min, and control the stirring temperature at 0-30°C.

[0039] 3) After the magnetic magnesium alloy melt has been dripped and added, the magnetic magnesium alloy nanoparticles formed in the ice ethanol bath are collected by centrifugation. The equipment used is an ultracentrifuge from Sigma, Germany, with a centrifugal speed of 9000r / min. Centrifug...

Embodiment 2

[0044] Preparation of magnesium alloy hyperthermia nanorobots:

[0045] 1) Drying and disinfection: the magnetic magnesium alloy nanoparticles with a particle size of 200-500nm prepared in Example 1 were placed in a vacuum environment below 50Pa for drying treatment, and then "ultraviolet-ozone" surface disinfection treatment was performed.

[0046] 2) Drug loading: Add 10 mg of paclitaxel to 50 mL of acetone and ultrasonically dissolve it completely, place it in a centrifuge tube, add 5 mg of the magnetic magnesium alloy nanoparticles treated in step 1), and place it in an ultracentrifuge (Sigma, Germany) at 9000r / min Centrifuge for 120 min, discard the supernatant, and place the centrifuge tube in a vacuum drying oven at 80° C. to dry to constant weight (about 70 min) to obtain a magnesium alloy hyperthermia nanorobot.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com