Pneumatic tire

A technology for pneumatic tires and tires, which is applied to tire parts, tire tread/tread pattern, transportation and packaging, etc. It can solve the problems of easy drop in noise performance and large groove area, so as to improve driving performance and suppress pattern noise , the effect of suppressing the transfer of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

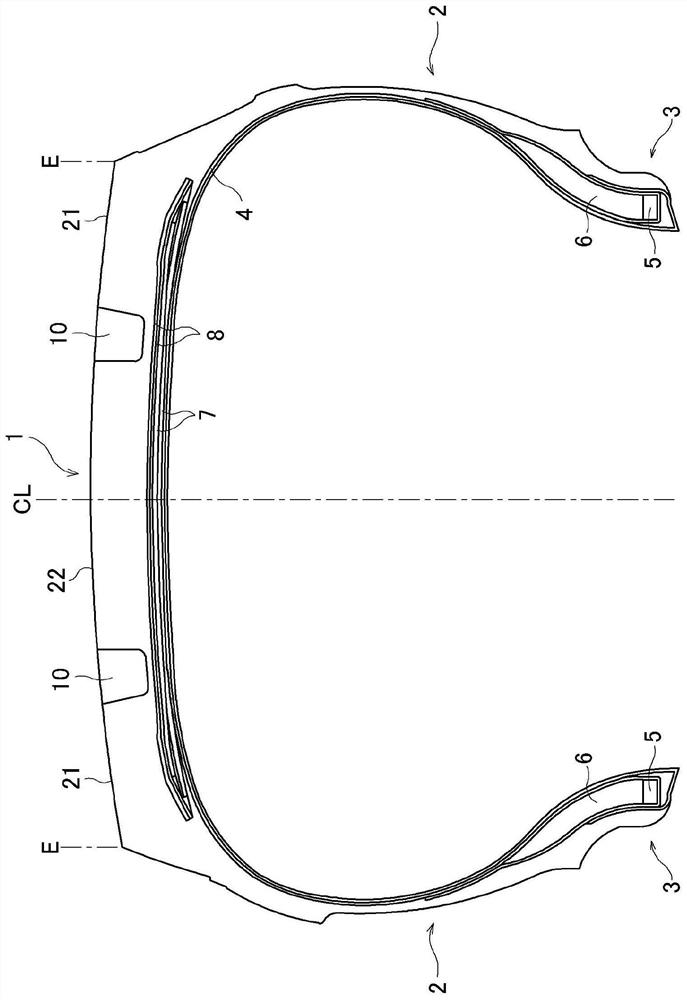

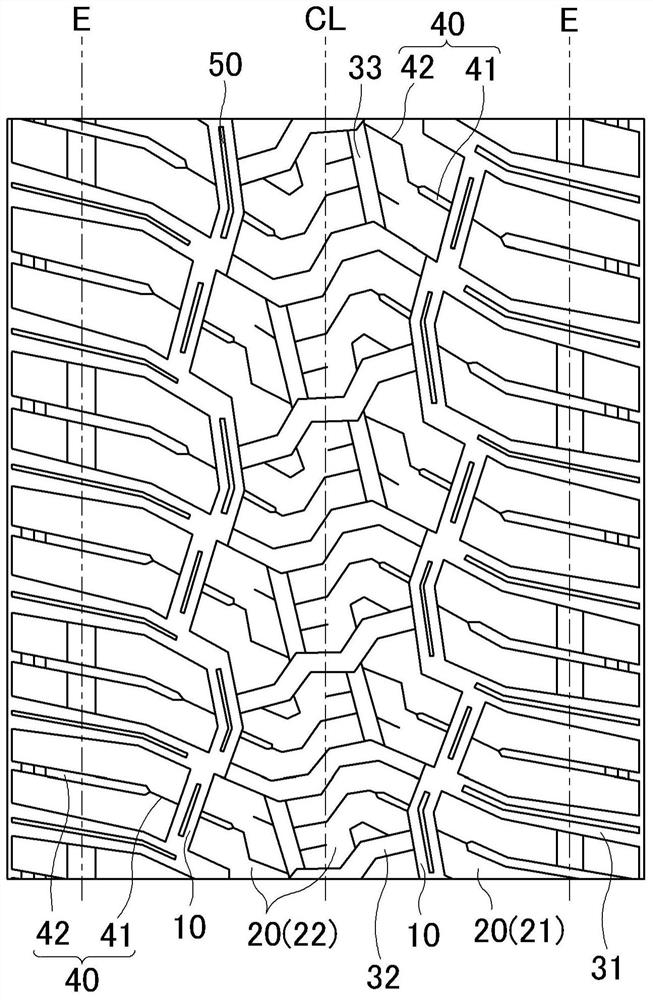

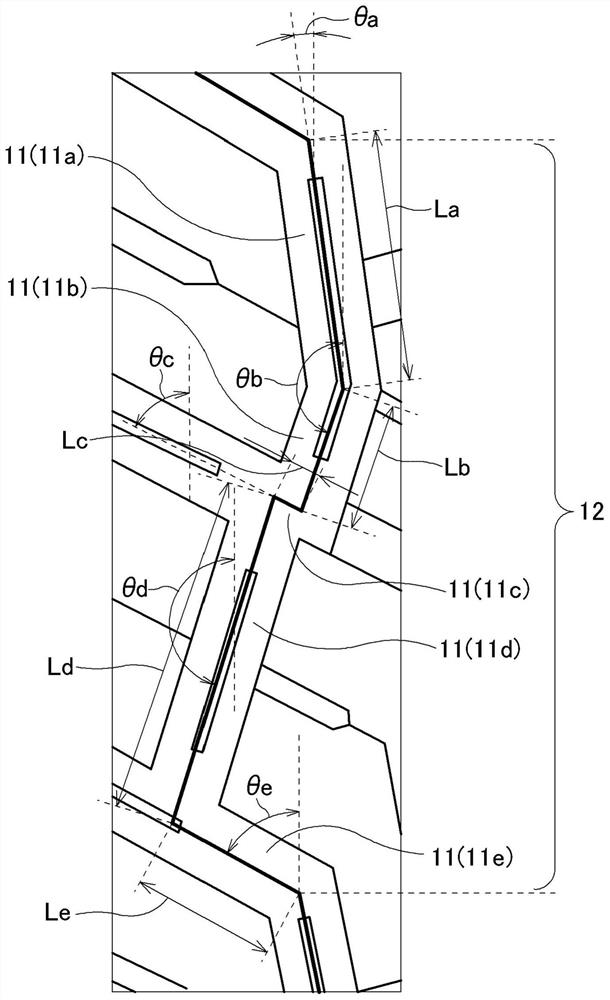

[0050] The tire size is LT265 / 70R17 121Q, with figure 1 The illustrated basic structure, with figure 2 The tread pattern of the tire is based on the number of linear grooves constituting the bending elements, the type of inclination angle of the linear grooves included in the bending elements with respect to the tire circumferential direction, the inclination angle of each linear groove, and the bending elements Types of the lengths of the linear grooves included in , the length of each linear groove (ratio to the total length of the linear grooves included in the bending element), the groove width of the main groove, the groove depth of the main groove, the main groove The position of the shoulder transverse groove, the groove depth of the shoulder transverse groove, the number of shoulder blocks arranged on the outside of one bending element in the tire width direction, the presence or absence of protrusions at the bottom of the groove, and the type of groove elements forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com