Electromechanical equipment data acquisition and analysis method

A technology of electromechanical equipment and data acquisition, applied in the direction of computer control, instruments, measuring devices, etc., can solve problems such as unfavorable discovery of problems, failure to ensure effective operation of electromechanical equipment, etc., to prevent the expansion of faults, good application prospects, and flexible applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

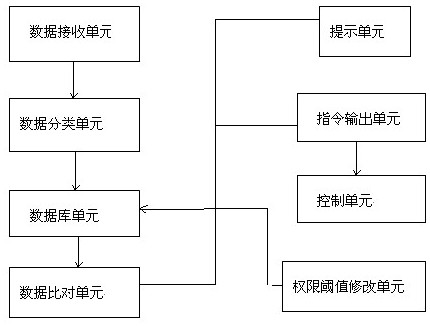

[0014] figure 1 As shown in , a method for data acquisition and analysis of electromechanical equipment, using a data receiving unit, a data classification unit, a database unit, a data comparison unit, a prompt unit, a permission threshold modification unit, a control unit, and an instruction output unit as the analysis application Software; use current acquisition sensor, voltage acquisition sensor, frequency acquisition sensor, speed acquisition sensor, temperature acquisition sensor, GPRS module, single chip microcomputer module with RS485 data port as the acquisition of electromechanical equipment working current, working voltage, working frequency, speed data and itself Equipment for temperature data and ambient temperature data; the current acquisition sensor, voltage acquisition sensor, frequency acquisition sensor, rotational speed acquisition sensor, and temperature acquisition sensor are installed at the electromechanical equipment required for data acquisition, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com