On-line monitoring device based on F level gas-steam combined unit generator rotor

A generator rotor and combined unit technology, which is applied in the direction of motor generator testing, measuring devices, and electrical measurement, can solve problems such as inability to monitor real-time position sensor signals, and achieve the effects of eliminating defects, quickly locating faults, and avoiding start-up failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

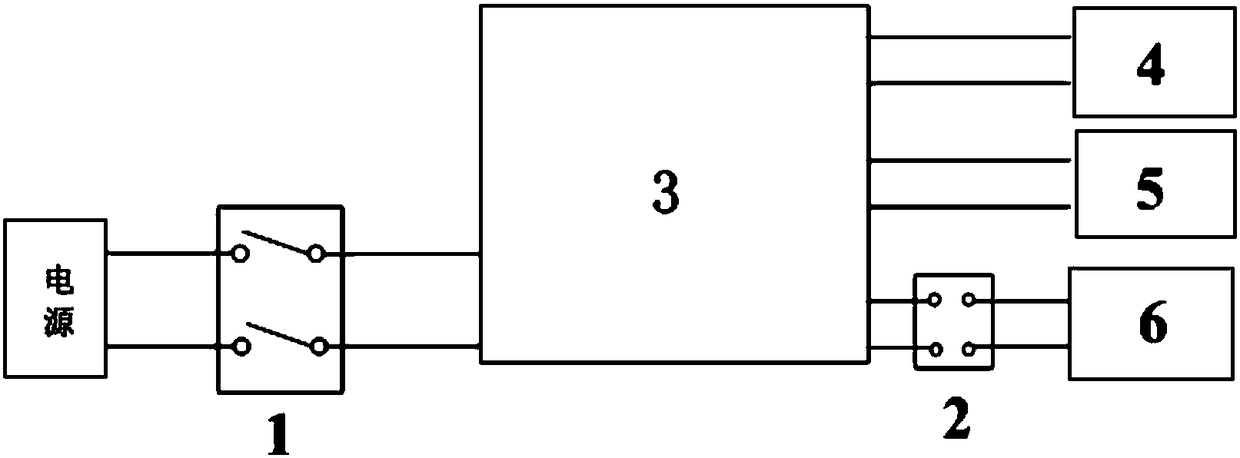

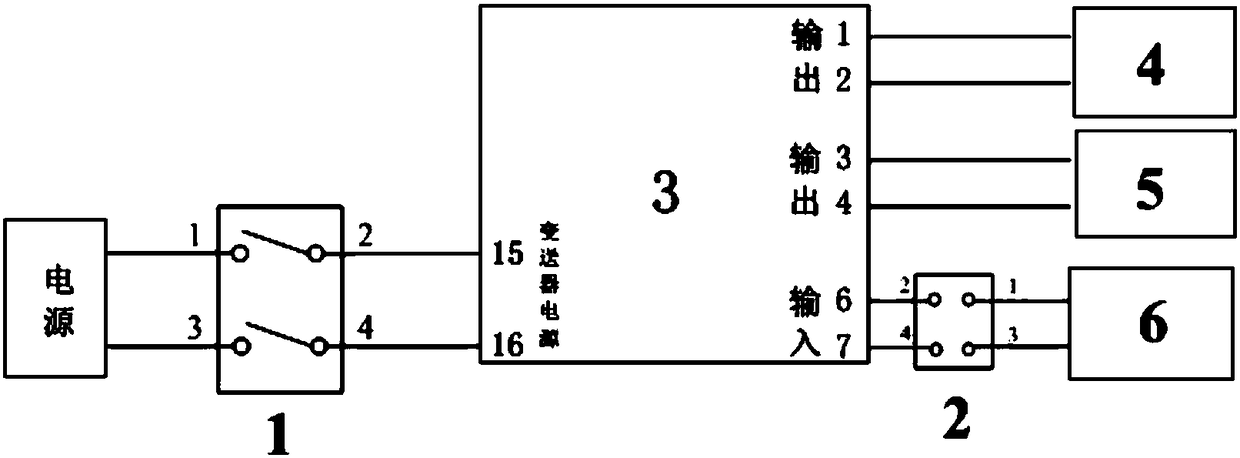

[0021] refer to figure 1 , the specific embodiment 1 includes a position sensor 6 electrically connected to the generator rotor, the signal output end of the position sensor 6 is connected to a voltage transmitter 3, so as to send the real-time position of the generator rotor to the voltage transmitter 3 , forming a real-time monitoring structure of the generator rotor; the voltage transmitter 3 is provided with a signal input terminal and two signal output terminals, the signal input terminal is connected with the signal output terminal of the position sensor 6, one of the signal output terminals Connect the control signal input end of DCS system 4, the two of signal output end connect the control signal input end of fault recorder 5; Described fault recorder 5 is used for recording the data information of position sensor 6 in operation process; The DCS system 4 is used to draw the waveform graphic of the signal of the position sensor 6 on the monitoring screen; form the onli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com