Intelligent refrigeration equipment maintenance management system and maintenance management method

A management system and refrigeration equipment technology, applied in refrigeration and liquefaction, refrigerators, refrigeration components, etc., can solve problems such as time-consuming and labor-intensive maintenance quality cannot be guaranteed, so as to ensure maintenance quality, reduce dependence on manual experience, and save time in operation Labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

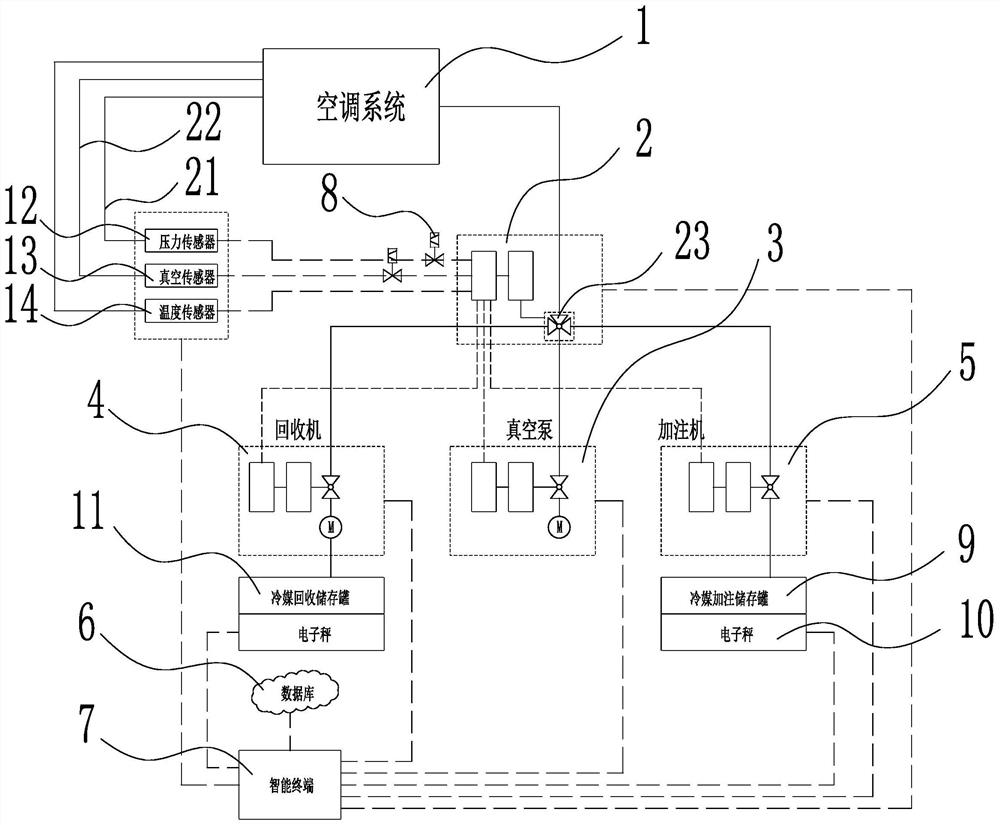

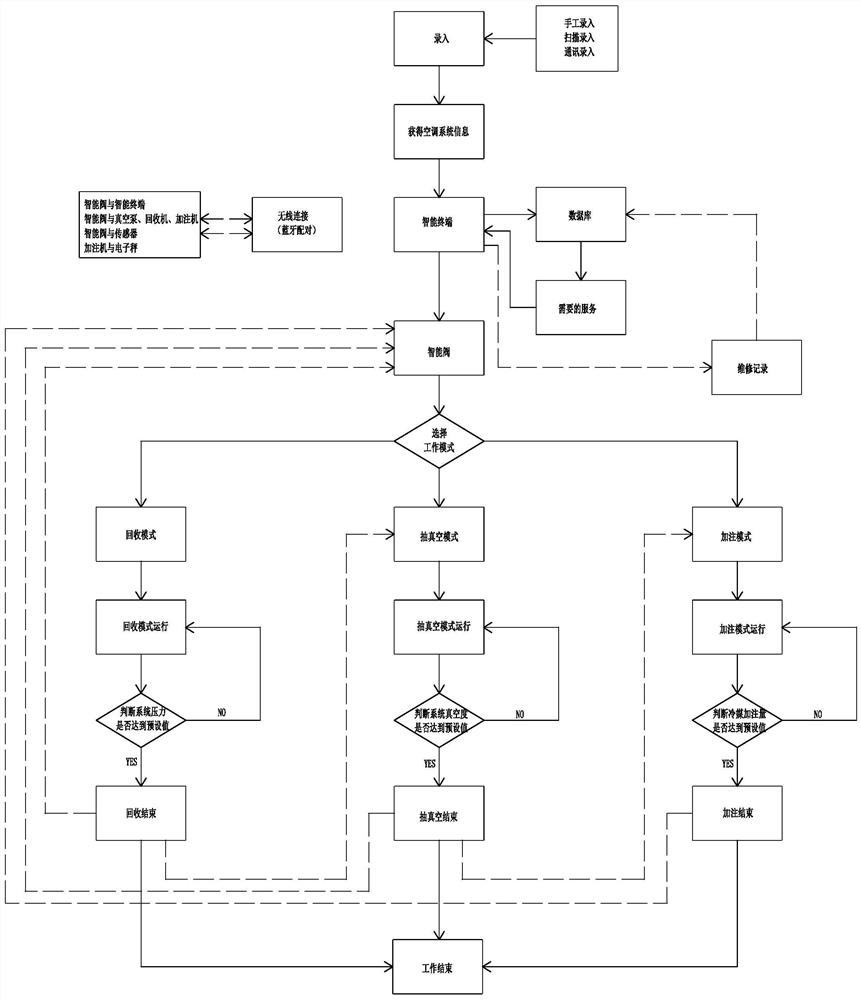

[0037] Such as figure 1As shown, an intelligent maintenance management system for refrigeration equipment of the present invention includes an air-conditioning system 1, a database 6 and an intelligent terminal 7. The high and low pressure ends of the air-conditioning system 1 are connected to the intelligent valve 2, and the intelligent valve 2 has an electric Three-way valve 23, high-pressure passage 21 and low-pressure passage 22, high-pressure passage 21 communicates with the high-pressure end of air-conditioning system 1, low-pressure passage 22 communicates with the low-pressure end of air-conditioning system 1, and the other end of high-pressure passage 21 and low-pressure passage 22 are connected to the motor One port of the three-way valve 23, the other two ports of the electric three-way valve 23 are respectively connected to the vacuum pump 3 and the recovery machine 4 (or filling machine 5), and the output end of the recovery machine 4 is connected to the refrigeran...

Embodiment 2

[0052] The smart valve 2 is connected to the vacuum pump 3 and the filling machine 5 , and the refrigerant filling storage tank 9 is placed on the electronic scale 10 . When the refrigerant filling operation is performed on the air-conditioning system 1, at the beginning of the operation, the pipeline between the filling machine 5 and the air-conditioning system 1 changes continuously at a constant speed from the closed state to the fully open state, and it takes 3 to 3 hours to fully open the state. 5 seconds. When the refrigerant filling of the air conditioning system 1 is nearing the end, the pipes of the filling machine 5 and the air conditioning system 1 change from the fully open state to the closed state at a continuous constant speed, and the time to the fully closed state is 0.5 to 1 second. All the other parts are identical to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com