Nitrogen-assisted carbon dioxide fracturing and developing integrated method for shale oil reservoir

A technology for carbon dioxide and shale oil, which is applied in the development of fluids, other gas emission reduction technologies, and earthwork drilling. The effect of chemical engineering, development economy, and enhanced oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

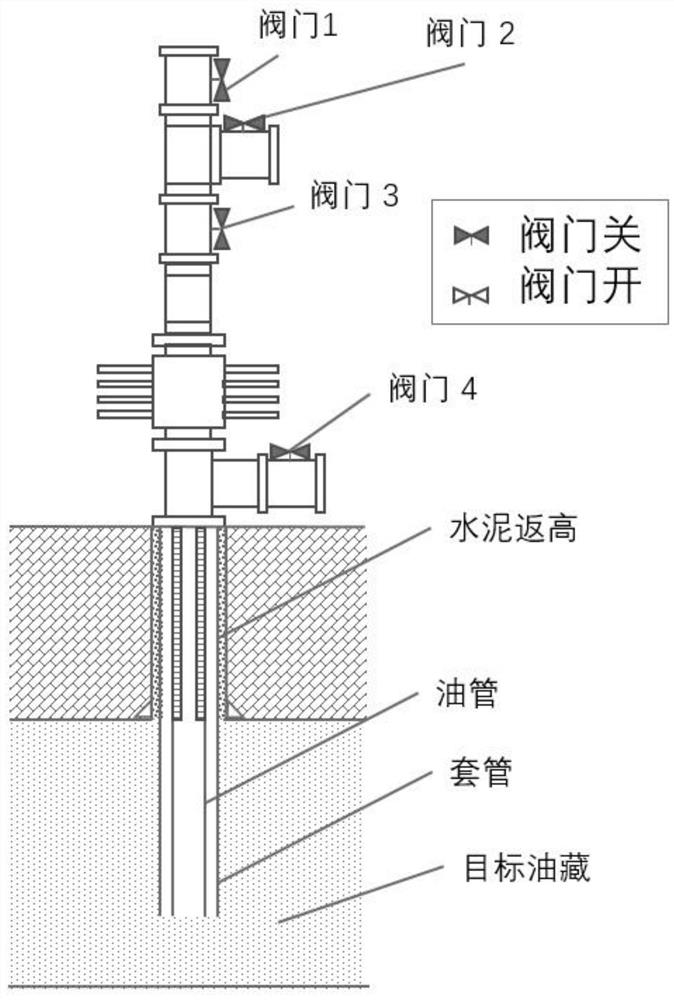

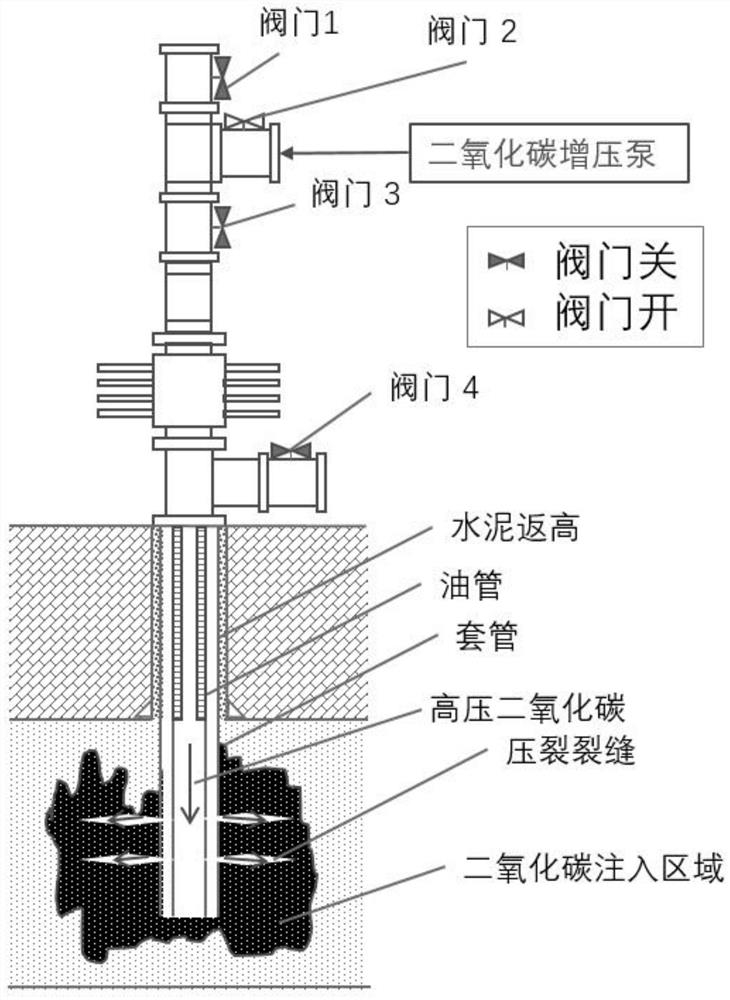

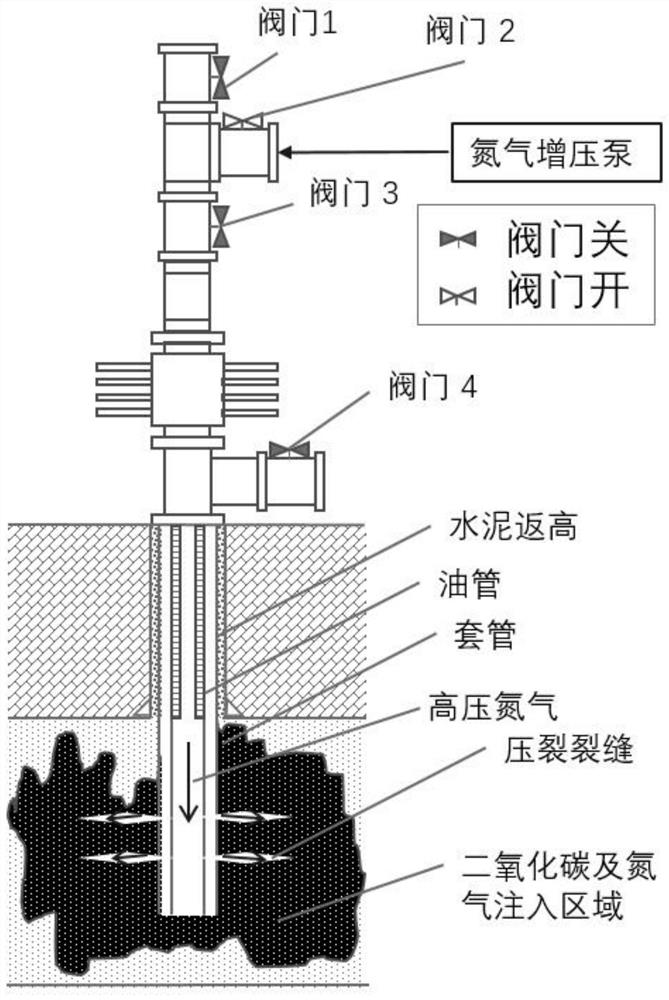

Method used

Image

Examples

experiment example

[0046] Using the long shale cores after fracturing, the huff and puff experiments of different gas media (pure carbon dioxide, carbon dioxide and nitrogen) were carried out. In experiment 1, the injected gas was pure carbon dioxide. In experiment 2, the gas injected was carbon dioxide first, and then nitrogen was injected to hold the pressure.

[0047] During the experiment, in each stimulation cycle, the injection volume of carbon dioxide was 0.1 times the pore volume, the soaking time was 10 hours, and the pressure depletion rate was 30kPa / min. After five cycles of throughput experiments, such as Figure 6 As shown, the recovery rate of Experiment 1 reached 28.51%, and under the pressure of nitrogen, the recovery rate of Experiment 2 reached 35.83%. Such as Figure 7 As shown, in Experiment 1, the volume of carbon dioxide injected in each round was the same, resulting in a gradual decrease in the pressure in the core, the pressure in the core could not be maintained, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com