Foundation bolt hot-dip galvanizing on-line automatic ash beating device

A technology of hot-dip galvanizing and anchor bolts, which is applied in the direction of hot-dip galvanizing, coating, metal material coating technology, etc., can solve the problems of high labor intensity, complex shape of the screw, and limited size of the zinc pot, etc., to achieve The effect of reducing labor intensity, simple structure, and avoiding long hours of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

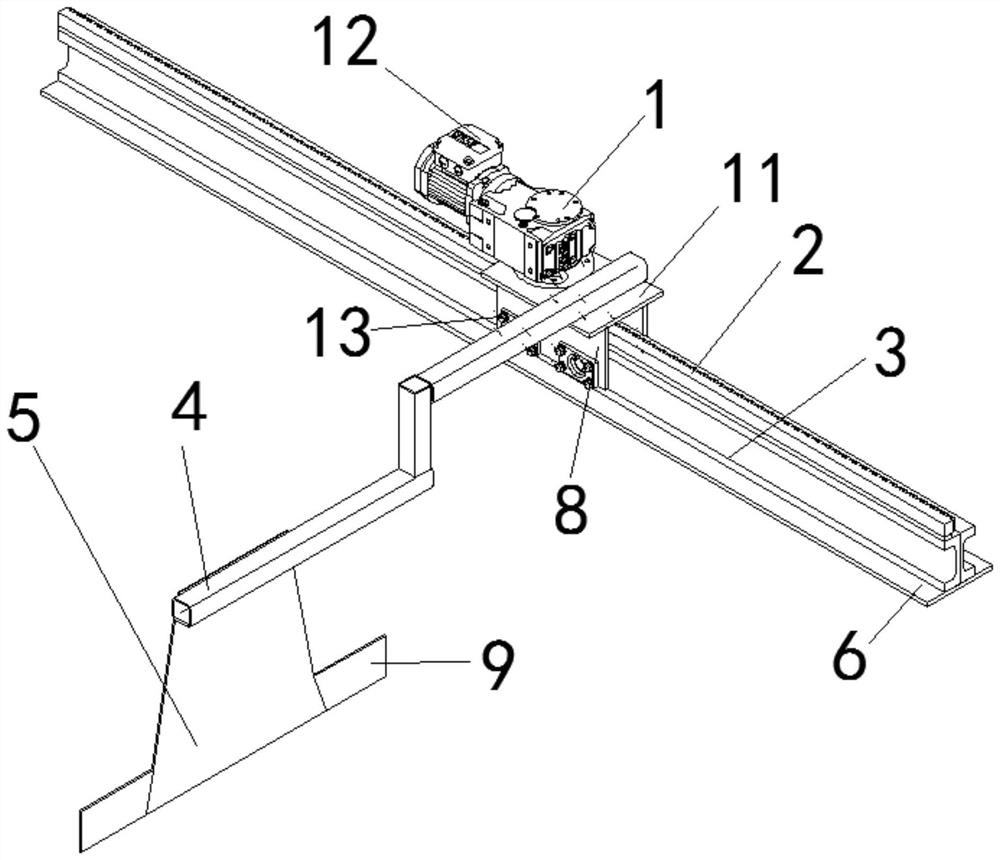

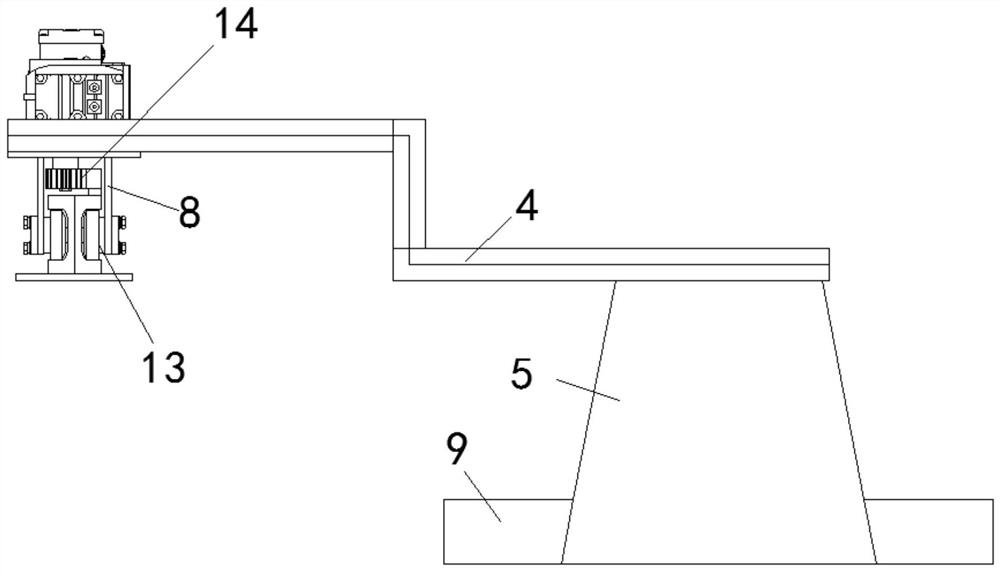

[0021] Embodiment 1: The moving guide rail 3 includes two symmetrically arranged C-shaped guide rails, the limiting device 13 is symmetrically arranged on the moving plate 11 , and the limiting device 13 includes a side plate 8 and a composite bearing 7 , and the composite bearing 7 cooperates with the C-shaped guide rail. Use to prevent the driving mechanism 1 from detaching from the moving guide rail 3 during operation, resulting in the occurrence of dangerous conditions.

Embodiment 2

[0022] Embodiment 2: The limiting device 13 is a dovetail groove, and the moving guide rail 3 is a trapezoidal guide rail, which is used together to prevent the driving mechanism 1 from detaching from the moving guide rail 3 during operation, resulting in the occurrence of dangerous working conditions.

[0023] The ash throwing board 5 is a trapezoidal structure, the long side of the ash throwing board 5 is far away from the fixing frame 4, and the two sides of the long side of the ash throwing board 5 are also provided with extension plates 9, which can increase the usable area of the ash throwing board 5, and has a wide range of applications and high working efficiency.

[0024] The motor 12 can be a three-phase motor 12, which is controlled by frequency conversion; it can also be a servo motor 12 controlled by an encoder; each ash-throwing process needs to have acceleration, average speed, and deceleration processes, and the ash-throwing time is strictly controlled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com