Refining process of refined brine for soda ash production

A refined brine and process technology, applied in the direction of alkali metal carbonates, alkali metal chlorides, alkali metal compounds, etc., can solve the problems of large fluctuations in calcium and magnesium content, reduce refined brine, increase the production cost of soda ash, etc., to reduce turbidity Degree, the effect of increasing the salt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

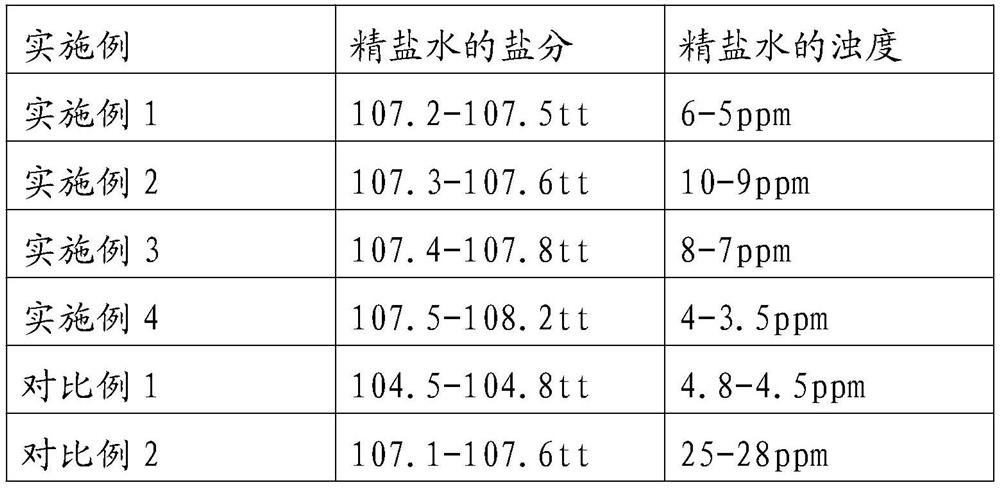

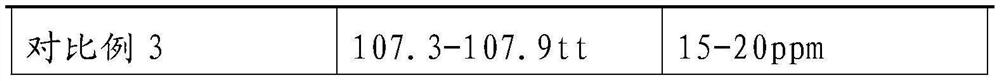

Examples

Embodiment 1

[0021] A process for refining refined brine for soda ash production, comprising the following steps:

[0022] (1) to the content of calcium ion less than 1.4tt, the content of magnesium ion is less than 2.5tt crude brine (temperature is 40 DEG C) while adding fine powder salt (the content of sodium chloride in the fine powder salt ≥ 95.5%, calcium magnesium ion ≤0.05%, sulfate ion ≤0.3%.) and causticizing liquid (the concentration of sodium carbonate in the causticizing liquid is 20tt and the concentration of sodium hydroxide is 35tt), and the addition of crude brine is 1100m 3 / h, the amount of causticizing liquid added is 50m 3 / h, the add-on of fine powder salt is 6 tons / h, and stirring and mixing obtains standby brine after the reaction of 30min;

[0023] (2) The standby brine in step (1) is added to the sedimentation aid solution during the transportation process, and the standby brine and the sedimentation aid solution are separated according to 900m 3 / h:10m 3 Add in...

Embodiment 2

[0025] A process for refining refined brine for soda ash production, comprising the following steps:

[0026] (1) to the content of calcium ion is less than 1.4tt, and the content of magnesium ion is less than 2.5tt crude brine (temperature is 43 ℃) and adds fine powder salt (the content of sodium chloride in fine powder salt ≥ 95.5%, calcium magnesium ion ≤0.05%, sulfate ion ≤0.3%.) and causticizing liquid (the concentration of sodium carbonate in the causticizing liquid is 25tt and the concentration of sodium hydroxide is 40tt), and the amount of crude brine added is 1150m 3 / h, the amount of causticizing liquid added is 55m 3 / h, the add-on of described fine powder salt is 6.5 tons / h, it is standby after stirring and mixing through the reaction of 35min;

[0027] (2) Add the settling aid solution to the spare brine in step (1) during the transportation process, and the spare brine and settling aid solution shall be prepared according to 1000m 3 / h:10m 3 Add in the ratio ...

Embodiment 3

[0029] A process for refining refined brine for soda ash production, comprising the following steps:

[0030] (1) to the content of calcium ion is less than 1.4tt, and the content of magnesium ion is less than 2.5tt crude brine (temperature is 43 ℃) and adds fine powder salt (the content of sodium chloride in fine powder salt ≥ 95.5%, calcium magnesium ion ≤0.05%, sulfate ion ≤0.3%.) and causticizing liquid (the concentration of sodium carbonate in the causticizing liquid is 25tt and the concentration of sodium hydroxide is 40tt), and the amount of crude brine added is 1150m 3 / h, the amount of causticizing liquid added is 55m 3 / h, the add-on of described fine powder salt is 6.5 tons / h, it is standby after stirring and mixing through the reaction of 35min;

[0031] (2) Add the settling aid solution to the spare brine in step (1) during the transportation process, and the spare brine and settling aid solution shall be prepared according to 1000m 3 / h:10m 3 Add in the ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com