Solid-liquid separation compression sleeve

A solid-liquid separation and compression sleeve technology, which is applied to presses, manufacturing tools, etc., can solve the problems of large output of hazardous waste, increased temporary storage space, and poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

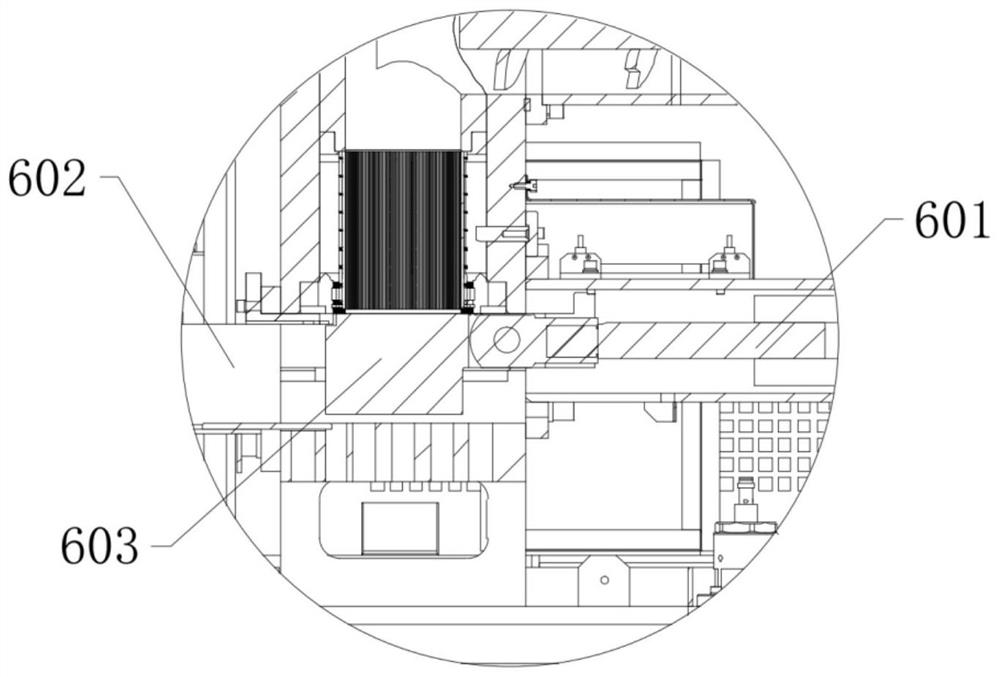

[0061] Embodiment: the present invention provides a kind of technical scheme: according to the description attached Figure 1-13 It can be seen that this case is a solid-liquid separation compression sleeve, which mainly includes: base 1, shell 2, silo 3, solid-liquid separation device 4, screw feeder 5 and block arrangement 6, the connection relationship is as follows:

[0062] The shell 2 is set on the base 1; the silo 3 is set on the shell 2; the solid-liquid separation device 4 is set inside the shell 2, and the solid-liquid separation device 4 performs solid-liquid separation on the materials in the silo 3; The screw feeder 5 is arranged on the housing 2, the screw feeder 5 is connected with the silo 3, and the feeding end of the screw feeder 5 is connected with the solid-liquid separation device 4, and the screw feeder 5 guides the material in the silo 3 The material moves into the solid-liquid separation device 4; the block arrangement 6 is arranged inside the housing 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com