High-pressure heating sand mold casting device

A technology of sand casting and high pressure, which is applied in the field of high-pressure heating sand casting devices, and can solve problems such as waste of casters, imperfect product performance, and inability to increase temperature and pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

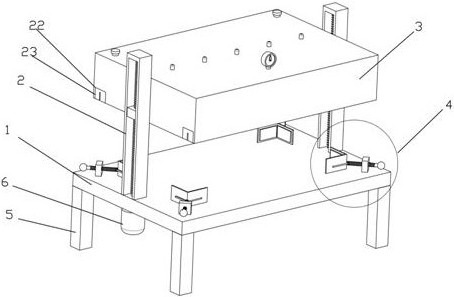

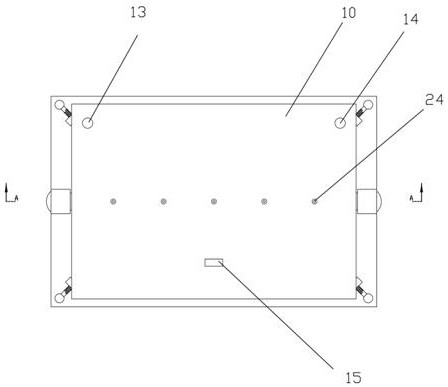

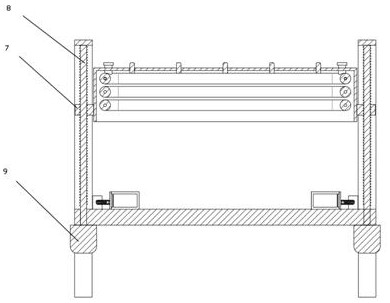

[0029] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0030] Please also refer to Figure 1 to Figure 4 , the high-pressure heating sand casting device of the embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] The high-pressure heating sand casting device includes a fixed plate 1, a vertical rod 2, a high-pressure heating component 3, and a clamping and fixing component 4. The bottom of the fixed plate 1 is fixed with a support rod 5, and there are four support rods 5. The fixed plate 1 The upper end is fixed with a vertical rod 2, and the vertical rod 2 is arranged symmetrically with respect to the middle of the fixed plate 1. The vertical rod 2 is slidingly connected with a lifting component 6 inside, and the high-pressure heating compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com