A kind of ruminant overwintering concentrate supplementary feed and production method

A technology for ruminants and feed, applied in the field of feed, can solve the problem that winter feeding can not meet the growth of animals in winter, and achieve the effects of shortening the feeding cycle, comprehensively balanced nutrition, and improving the feed conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

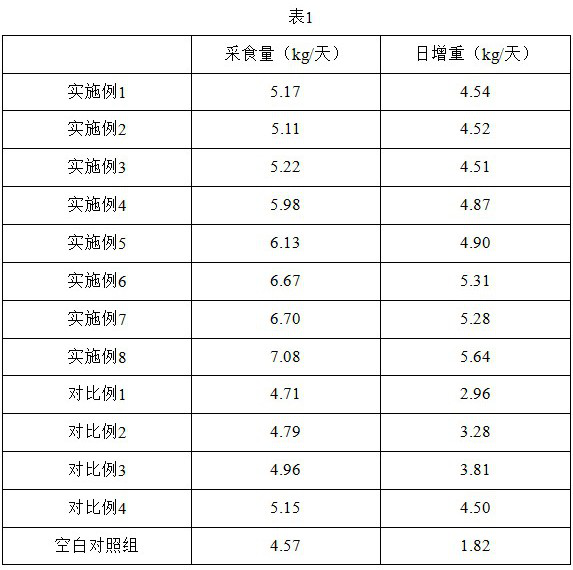

Image

Examples

Embodiment 1

[0050] A production method for overwintering concentrate supplementary feed for ruminants, comprising the following steps:

[0051] S1. Raw material crushing: crush 220kg of corn to a particle size of 2.4mm; crush 15kg of soybean meal, 22kg of cottonseed meal, 30kg of bran, 40kg of DDGS, 28kg of rapeseed meal, 190kg of sunflower seeds, 350kg of sprayed corn husk, 25kg of stone powder, and 60kg of bentonite respectively crushed to a particle size of 3.1mm;

[0052] S2. mixing of raw materials: mixing the pulverized raw materials of step a, adding sodium chloride 8kg, ammonium chloride 1kg, copper sulfate 0.04kg, ferrous sulfate 0.06kg, zinc sulfate 0.3kg, manganese sulfate 0.3kg, potassium iodide 0.002kg, Cobalt Sulfate 0.0025kg, Sodium Selenite 0.0009kg, Vitamin A 0.0025kg, Vitamin D 3 8.72×10 -5 kg, vitamin E 0.1kg, stir for 15s under the condition that the stirring speed is 500rpm / min, add 42kg of sugarcane molasses after stirring, and then stir for 95s under the conditio...

Embodiment 2

[0057] A production method for overwintering concentrate supplementary feed for ruminants, comprising the following steps:

[0058] S1. Crushing of raw materials: crush 180kg of corn to a particle size of 2.6mm; 25kg of soybean meal, 18kg of cottonseed meal, 34kg of bran, 30kg of DDGS, 32kg of rapeseed meal, 170kg of sunflower seeds, 360kg of sprayed corn husk, 20kg of stone powder, and 40kg of bentonite respectively crushed to a particle size of 2.9mm;

[0059] S2. mixing of raw materials: mixing the pulverized raw materials of step a, adding sodium chloride 10kg, ammonium chloride 3kg, copper sulfate 0.03kg, ferrous sulfate 0.07kg, zinc sulfate 0.25kg, manganese sulfate 0.32kg, potassium iodide 0.0019kg, Cobalt Sulfate 0.003kg, Sodium Selenite 0.00088kg, Vitamin A 0.0028kg, Vitamin D 3 8.7×10 -5 kg, vitamin E 0.12kg, stir for 25s under the condition that the stirring speed is 300rpm / min, add 38kg of sugarcane molasses after stirring evenly, and then stir for 105s under th...

Embodiment 3

[0064] A production method for overwintering concentrate supplementary feed for ruminants, comprising the following steps:

[0065] S1. Crushing of raw materials: crush 200kg of corn to a particle size of 2.5mm; 20kg of soybean meal, 20kg of cottonseed meal, 32kg of bran, 35kg of DDGS, 30kg of rapeseed meal, 180kg of sunflower seeds, 354kg of sprayed corn husk, 23kg of stone powder, and 50kg of bentonite respectively crushed to a particle size of 3.0mm;

[0066] S2. mixing of raw materials: mixing the pulverized raw materials of step a, adding sodium chloride 9kg, ammonium chloride 2kg, copper sulfate 0.0348kg, ferrous sulfate 0.0648kg, zinc sulfate 0.271kg, manganese sulfate 0.314kg, potassium iodide 0.00195kg, Cobalt Sulfate 0.00262kg, Sodium Selenite 0.000893kg, Vitamin A 0.00272kg, Vitamin D 3 8.71×10 -5 kg, vitamin E 0.104kg, stir for 20s under the condition that the stirring speed is 400rpm / min, add 40kg of sugarcane molasses after stirring evenly, and then stir for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com