Preparation method and application of electrochemical immunosensor based on enzyme induction

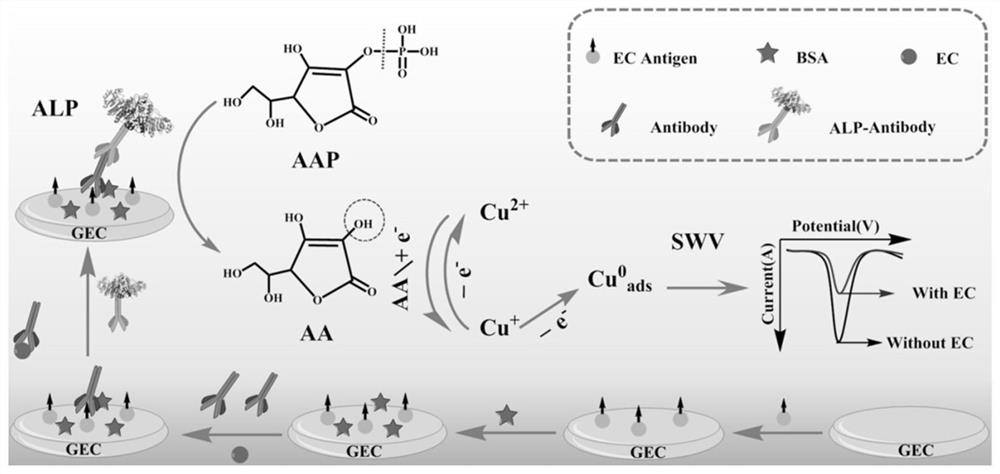

An immunosensor and electrochemical technology, applied in the field of electrochemistry, can solve the problems that the sensitivity of molecularly imprinted electrochemical sensors cannot meet the detection requirements, and achieve the effects of low detection cost, simple operation, high sensitivity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Electrode cleaning

[0044] The glassy carbon electrode was polished sequentially with polishing powders with particle sizes of 1.0 μm, 0.3 μm, and 0.05 μm, then cleaned with ultrapure water, ultrasonicated for 10 s, and finally washed again with ultrapure water.

[0045] 2. Probe construction

[0046] Add 6 μL of urethane-coated original (10 μg / mL Ag) to the glassy carbon electrode to be used, incubate for 1 hour, wash with pH7.4 0.1MPBS buffer three times, and wash off the urethane that is not immobilized on the electrode Coating original; soak the glassy carbon electrode in 1% BSA solution to seal for 0.5h, wash with pH7.4 0.1M PBS buffer three times to wash off excess BSA; then soak the glassy carbon electrode in pH7.4 0.1M PBS Incubate in urethane indirect rabbit polyclonal antibody (10μg / mL Ab1) prepared in buffer for 0.5h; wash with pH 7.4 0.1M PBS buffer three times to wash off unbound urethane indirect rabbit polyclonal antibody; finally, glass Soak the carb...

Embodiment 2

[0055] 1. Electrode cleaning

[0056] Cleaning of the electrode: Polish with 1.0 μm, 0.3 μm, and 0.05 μm polishing powder in sequence, then clean with ultrapure water, then ultrasonic for 10 s, and finally wash with ultrapure water to obtain a glassy carbon electrode to be used.

[0057] 2. Probe construction

[0058] Add 20 μL of urethane-coated original (40 μg / mL Ag) to the glassy carbon electrode to be used, incubate for 1 hour, wash with pH7.4 0.1M PBS buffer three times, and wash off the urethane that is not fixed on the electrode Coating original; Soak the glassy carbon electrode in 1% BSA solution to seal for 1h, wash with pH7.4 0.1M PBS buffer three times to wash off excess BSA; then soak the glassy carbon electrode in pH7.4 0.1M PBS Incubate in urethane indirect rabbit polyclonal antibody (40μg / mL Ab1) prepared in buffer for 1h; wash with pH7.4 0.1M PBS buffer three times to wash off unbound urethane indirect rabbit polyclonal antibody; finally, glass Soak the carbo...

Embodiment 3

[0067] 1. Electrode cleaning

[0068] Cleaning of the electrode: Polish with 1.0 μm, 0.3 μm, and 0.05 μm polishing powder in sequence, then clean with ultrapure water, then ultrasonic for 10 s, and finally wash with ultrapure water to obtain a glassy carbon electrode to be used.

[0069] 2. Probe construction

[0070] Drop 10 μL of urethane-coated original (20 μg / mL Ag) to the glassy carbon electrode to be used, incubate for 1 h and wash with pH7.4 0.1MPBS buffer three times to wash off the urethane coating not fixed on the electrode. Cover the original; soak the glassy carbon electrode in 1% BSA solution for 1 hour, wash with pH7.4 0.1M PBS buffer three times to wash off excess BSA; then soak the glassy carbon electrode in pH7.4 0.1M PBS buffer Incubate in the prepared urethane indirect rabbit polyclonal antibody (15 μg / mL Ab1) for 1 h; wash with pH7.4 0.1M PBS buffer three times to wash off the unbound urethane indirect rabbit polyclonal antibody; finally, the glassy carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com