Ballastless track plate structure for realizing broadband vibration attenuation based on photonic crystal principle

A ballastless orbital and phononic crystal technology, applied in orbits, roads, ballast layers, etc., can solve the problems such as the combination of periodic structure vibration reduction and orbital structure, large structure size, and low band gap frequency. Achieve the effect of simple structure, small size, and increased vibration displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

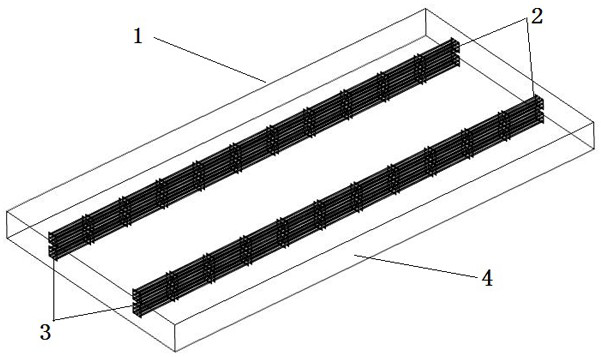

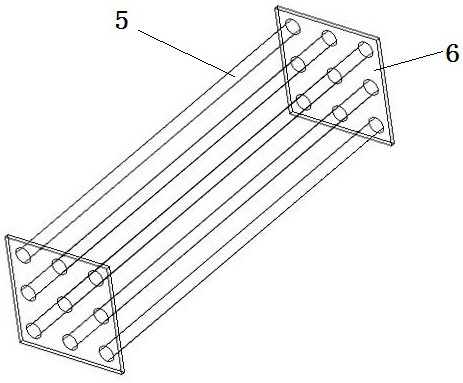

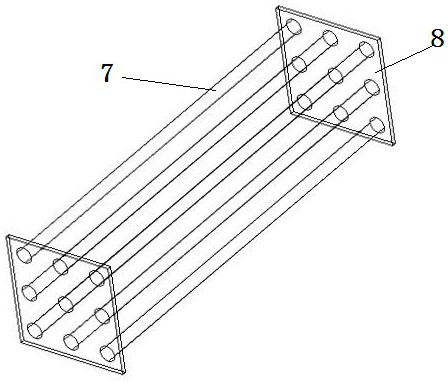

[0019] Example: as attached Figure 1-3 As shown, a ballastless track slab structure based on the principle of phononic crystals to achieve broadband vibration reduction includes a ballastless track slab damping structure 1, which is damped by periodic steel columns repeatedly arranged along the line direction. The vibration device 2, the periodic rubber column vibration damping device 3 and the track plate 4 are composed of three parts. The periodic steel column vibration damping device 2 and the periodic rubber column vibration damping device 3 are all located in the track plate 4 below the track position. The periodic rubber column vibration damping device 3 is placed under the periodic steel column vibration damping device 2, and there may or may not be a gap between the two. The periodic steel column damping device 2 is composed of steel bars 5 and steel plates 6 , and the periodic rubber column damping device 3 is composed of rubber columns 7 and rubber plates 8 . The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com