Macroporous adsorption resin for lincomycin extraction and synthesis method thereof

A technology of lincomycin and a synthesis method, which is applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve the problems of high production cost of macroporous adsorption resin, large emission of organic solvents, and low purity of finished products. , to achieve the effect of efficient extraction and industrial production, large adsorption capacity and high purity of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

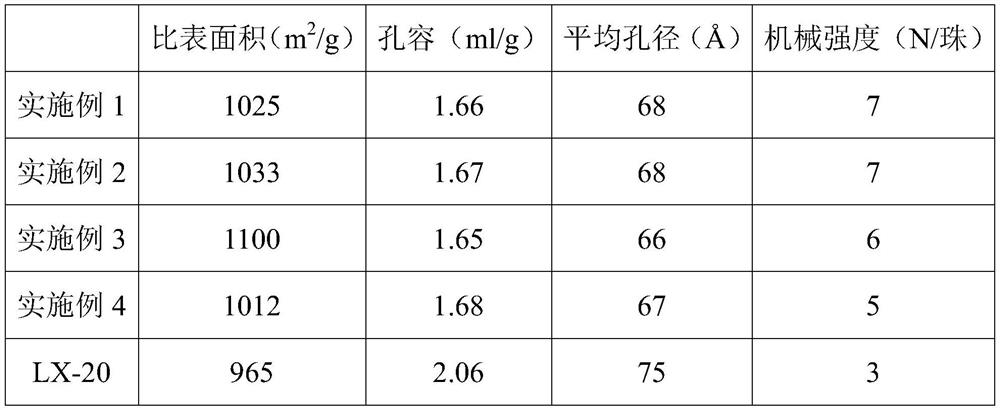

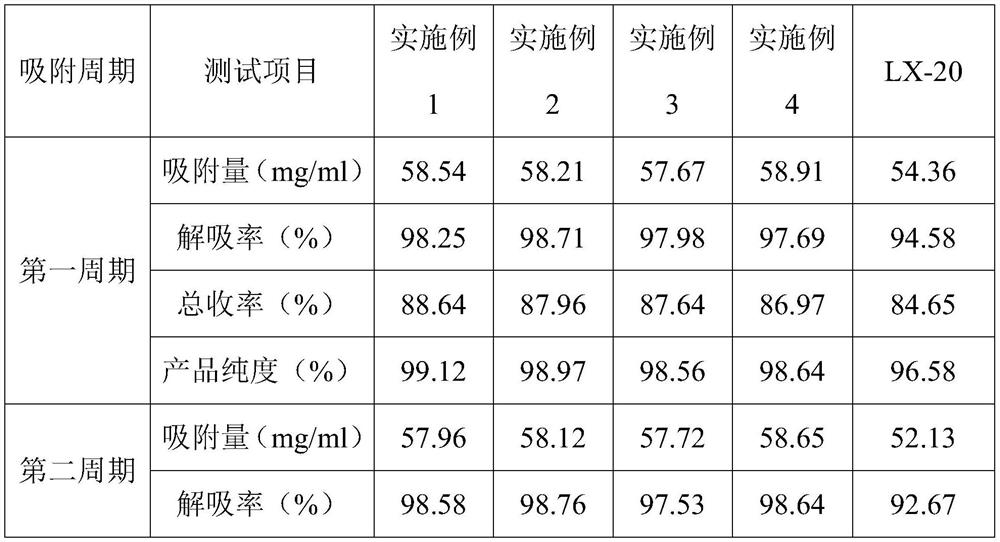

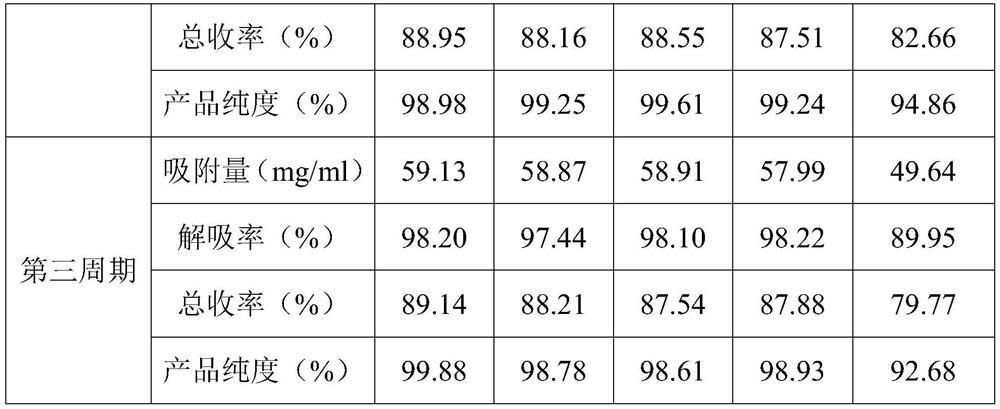

Examples

preparation example Construction

[0032] A kind of synthetic method of macroporous adsorption resin for lincomycin extraction of the present invention comprises the following steps:

[0033] S1, synthesizing polystyrene-divinylbenzene type copolymer;

[0034] Add the dispersant and methylene blue into the water and heat, stir until completely dissolved to form the water phase; mix the monomer, porogen and initiator evenly as the oil phase; add the oil phase to the prepared water phase , let it stand for 5-10 minutes, after the oil phase and the water phase are completely separated, adjust the height and speed of the stirring paddle to control the particle size of the oil phase, stir at a constant speed after the particle size is appropriate, and then carry out heating and heat preservation operations; wash off with hot water after the reaction For the dispersant on the surface of the resin, the porogen inside the resin is extracted by water vapor extraction, and then washed and dried to obtain a polystyrene-di...

Embodiment 1

[0046] The oil phase mixture that will contain 100g divinylbenzene (content 80%), 150g tetramethylbenzene and 1.5g benzoyl peroxide is added to 500ml tap water, 2.5g polyvinyl alcohol, 2.5g hydroxyethyl cellulose and 0.025g times In the water phase solution composed of methylene blue, let it stand for 5 to 10 minutes. After the oil phase and the water phase are completely separated, adjust the stirring speed to make it into a uniform droplet of a certain size, then keep stirring at a constant speed and slowly heat up to 80 °C for 2 hours, 90 °C for 2 hours, and 95 °C for 6 hours. After the reaction is over, rinse the polystyrene-divinylbenzene copolymer with hot water, then add it to the steam extractor, perform steam purging at 90°C to recover the porogen tetramethylbenzene, and extract it into the outlet condensate There is almost no oily matter, the extraction is stopped, and finally the temperature is cooled and the material is discharged. The recovery rate of tetramethylb...

Embodiment 2

[0049] The oil phase mixture containing 100g divinylbenzene (content 80%), 150g recovery tetramethylbenzene and 1.5g benzoyl peroxide was added to 500ml tap water, 2.5g polyvinyl alcohol, 2.5g hydroxyethyl cellulose and 0.025g In the water phase solution composed of methylene blue solution, let it stand for 5 to 10 minutes. After the oil phase and the water phase are completely separated, adjust the stirring speed to make it into a uniform droplet of a certain size, and then keep stirring at a constant speed and slowly Raise the temperature to 80°C for 2 hours, 90°C for 2 hours, and 95°C for 6 hours. After the reaction is over, rinse the polystyrene-divinylbenzene copolymer with hot water, then add it to the steam extractor, perform steam purging at 95°C to recover the porogen tetramethylbenzene, and extract it into the outlet condensate There is almost no oily matter, the extraction is stopped, and finally the temperature is cooled and the material is discharged. The recovery...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com