Comprehensive utilization device and method for waste in PVB resin production process

A production process and waste technology, applied in chemical instruments and methods, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as the impact of condensation process and product quality, and achieve steam saving, The effect of reducing evaporation steam consumption and avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

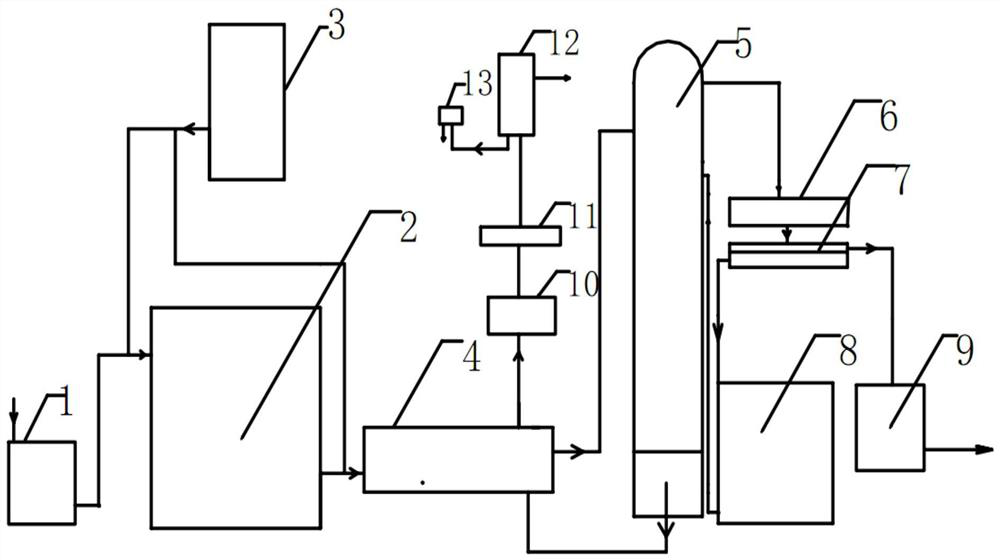

[0035] like figure 1 , the comprehensive utilization device of the waste in a kind of PVB resin production process of the present embodiment, comprises waste collection tank 1, feed tank 2, lye tank 3, feed preheater 4, butyraldehyde removal tower 5, Condenser 6, phase separator 7, reflux tank 8, butyraldehyde storage tank 9, kettle liquid collection tank 10, concentration device 11, evaporation device 12 and crystallization device 13.

[0036] The material outlet of the waste collection tank 1 is connected to the material inlet of the feed tank 2; the material outlet of the feed tank 2 is connected to the first material inlet of the feed preheater 4; the material outlet of the lye tank 3 is connected to the inlet in parallel. The material inlet of feed tank 2 and the first material inlet of feed preheater 4 .

[0037] The first material outlet of the feed preheater 4 is connected to the first material inlet of the butyraldehyde removal tower 5; the discharge port of the buty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com