Air valve membrane material, air valve membrane and inflatable bag

A technology of air valve film and inflatable bag, which is used in bags, sacks, transportation and packaging, etc., can solve the problems of waste generation, inability to adapt to high-speed inflatable equipment, and inflatable bag air-holding effect can not be lasting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

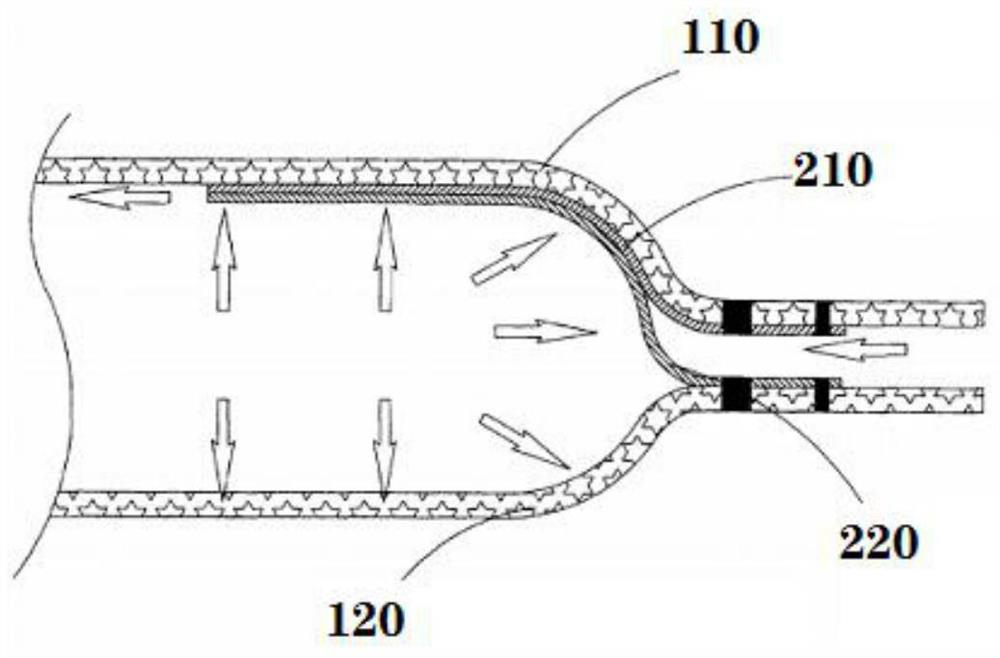

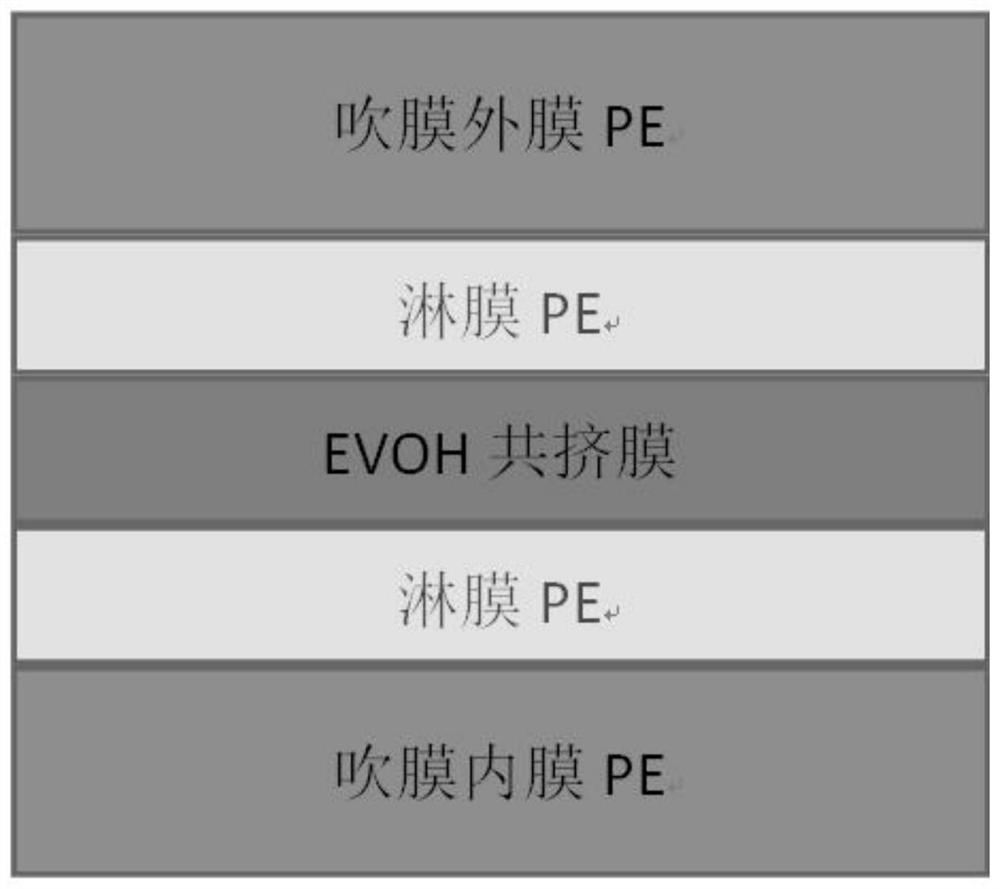

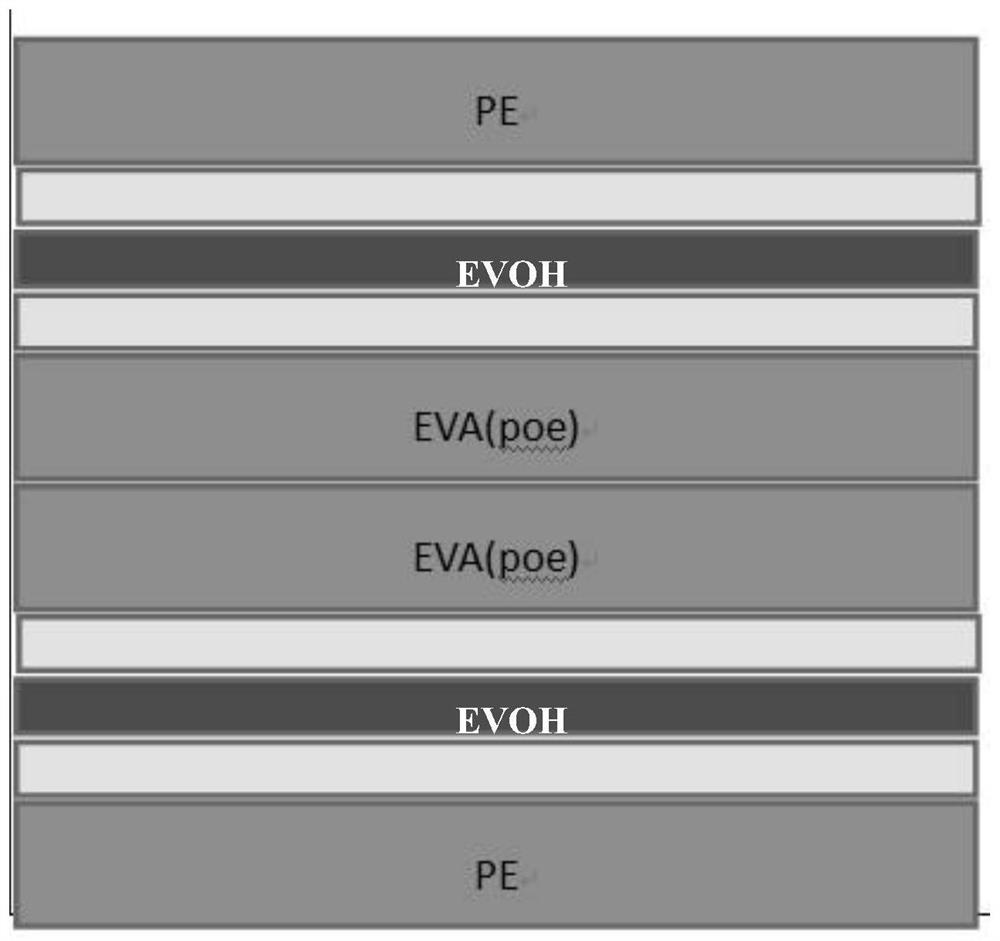

[0073] refer to Figure 4 , a kind of one-way check valve inflatable bag of the present invention, comprises base film 100, and base film 100 comprises upper base film 110 and lower base film 120, is provided with opening between upper base film 110 and lower base film 120; Air valve The film 200 is arranged at the opening between the upper bottom film 110 and the lower bottom film 120. The air valve film 200 includes a first air valve film layer 210 and a second air valve film layer 220. The first air valve film layer 210 is close to the upper bottom. Membrane 110, the second air valve film layer 220 is close to lower bottom film 120, and air valve film 200 and bottom film 100 all comprise such as Figure 5 The multi-film layer structure 300 shown includes a polyethylene outer layer 310, a polyethylene inner layer 322, an adhesive resin layer 321, and an intermediate barrier layer 323; the multi-film layer structure 300 is prepared by one-time blown film molding by a co-extru...

Embodiment 2

[0088] refer to Figure 4 , a kind of one-way check valve inflatable bag of the present invention, comprises base film 100, and base film 100 comprises upper base film 110 and lower base film 120, is provided with opening between upper base film 110 and lower base film 120; Air valve The film 200 is arranged at the opening between the upper bottom film 110 and the lower bottom film 120. The air valve film 200 includes a first air valve film layer 210 and a second air valve film layer 220. The first air valve film layer 210 is close to the upper bottom. Membrane 110, the second air valve film layer 220 is close to lower bottom film 120, and air valve film 200 and bottom film 100 all comprise such as Figure 5 The multi-film layer structure 300 shown includes a polyethylene outer layer 310, a polyethylene inner layer 322, an adhesive resin layer 321, and an intermediate barrier layer 323; the multi-film layer structure 300 is prepared by one-time blown film molding by a co-extru...

Embodiment 3

[0101] refer to Figure 4 , a kind of one-way check valve inflatable bag of the present invention, comprises base film 100, and base film 100 comprises upper base film 110 and lower base film 120, is provided with opening between upper base film 110 and lower base film 120; Air valve The film 200 is arranged at the opening between the upper bottom film 110 and the lower bottom film 120. The air valve film 200 includes a first air valve film layer 210 and a second air valve film layer 220. The first air valve film layer 210 is close to the upper bottom. Membrane 110, the second air valve film layer 220 is close to lower bottom film 120, and air valve film 200 and bottom film 100 all comprise such as Figure 5 The multi-film layer structure 300 shown includes a polyethylene outer layer 310, a polyethylene inner layer 322, an adhesive resin layer 321, and an intermediate barrier layer 323; the multi-film layer structure 300 is prepared by one-time blown film molding by a co-extru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com