Stable clamping and centering device for spare and accessory part machining

A kind of spare parts and stable technology, applied in the field of spare parts processing, can solve problems such as affecting the normal progress of production, lack of centering device for clamping device, inability to effectively determine the center of spare parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

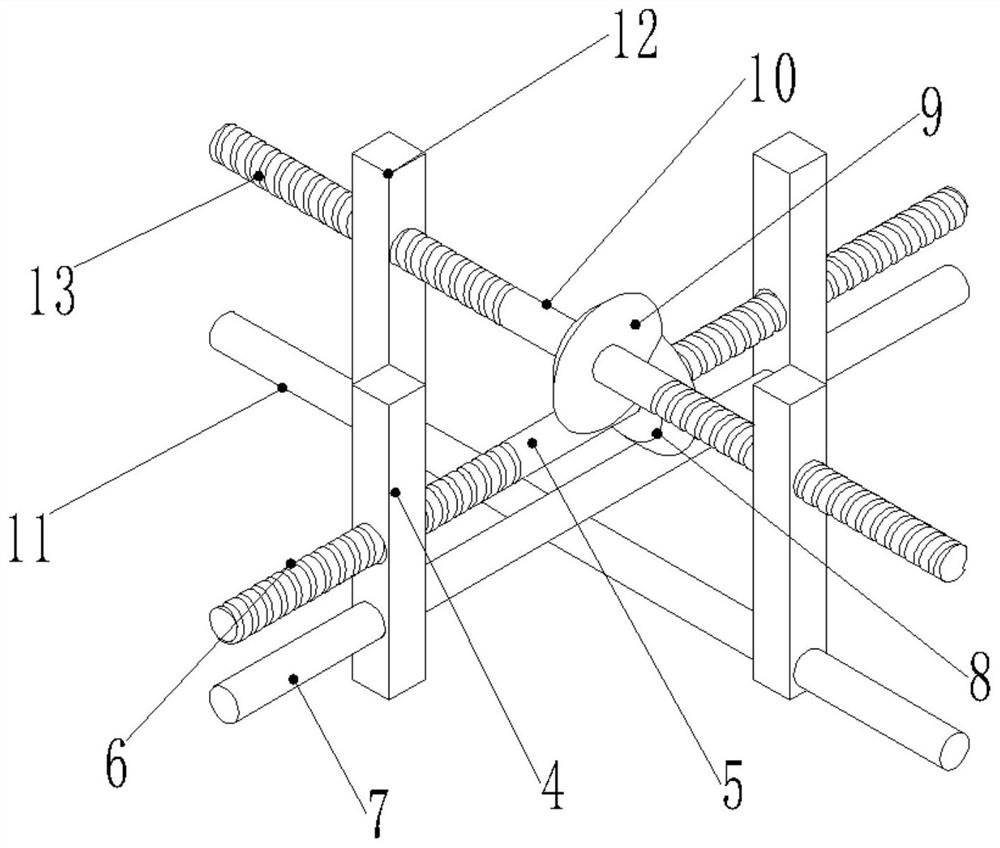

[0025] see Figure 1~6 , in an embodiment of the present invention, a stable clamping and centering device for spare parts processing includes a control box 1 and a clamping platform 2, and the clamping platform 2 is fixedly connected and arranged on the top of the control box 1, so that The clamping platform 2 includes a platform body 21 and a chute 22, the chute 22 is set through the platform body 21, a clamping block 3 is slidably connected in the chute 22, and a clamping mechanism is arranged in the control box 1 to clamp The mechanism is connected to the clamping block 3. The clamping mechanism includes a horizontal clamping structure and a longitudinal clamping structure. Both the horizontal clamping structure and the longitudinal clamping structure are provided with a clamping block 3. At the same time, the spare parts on the clamping platform 2 are clamped, which has a good centering effect.

[0026] see Figure 1~3 , the transverse clamping structure comprises a tra...

Embodiment 2

[0031] see figure 1 and Figure 4 , in the embodiment of the present invention, a stable clamping and centering device for parts processing, four groups of the chute 22 are evenly distributed on the circumference of the table body 21, the four groups of chute 22 are connected to each other, and the four groups of chute Clamping blocks 3 are arranged in sliding connection in the slots 22 , which can prevent clamping at the communication points of the four groups of sliding slots 22 for spare parts with smaller dimensions.

[0032] see Figure 5-6 The side of the vertical plate 32 away from the horizontal plate 31 is provided with a sliding groove 37, and the side of the vertical plate 32 close to the horizontal plate 31 is provided with a limiting chute 38, and the sliding groove 37 and the limiting chute 38 are communicated with and provided with Connecting hole 39, sliding connection is provided with slide plate 33 in described sliding groove 37, and limit plate 36 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com