Efficient polishing-free automatic pipe making machine and pipe making method

A non-grinding, automatic manufacturing technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as uneven welds, low production efficiency, uneven grinding marks, etc., to solve bad problems, improve production efficiency, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

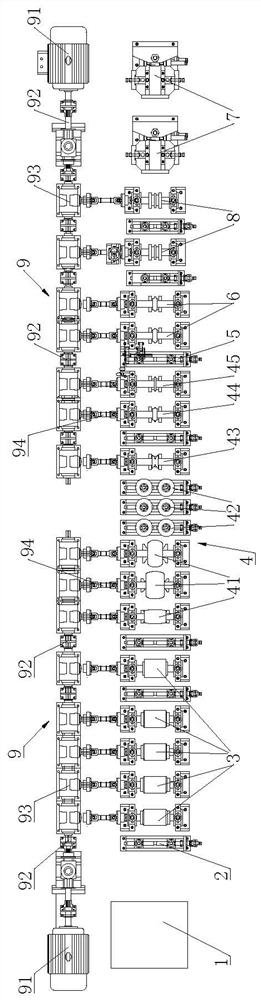

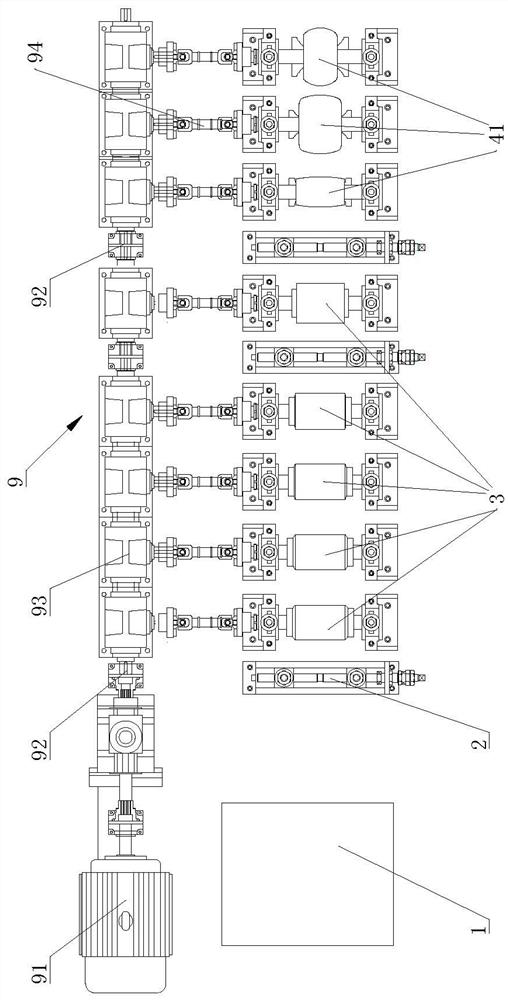

[0034] Figure 1-12 A high-efficiency grinding-free automatic pipe making machine according to an embodiment of the present invention is schematically shown.

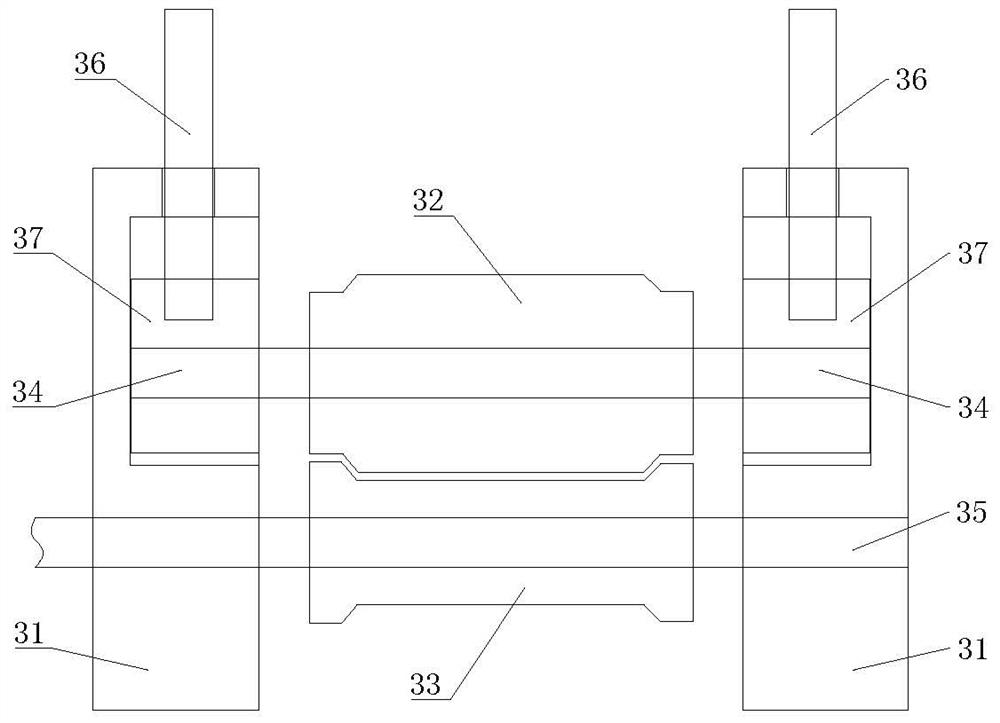

[0035] refer to Figure 1-12 The high-efficiency grinding-free automatic pipe making machine includes a steel strip unwinding device 1, a steel strip flattening device 2, a steel strip folding device 3, a steel strip closing device 4, a closing welding device 5, and a weld seam flattening device 8 arranged in sequence , Steel pipe shaping device 6, shaping and sizing device 7 and power transmission device 9. The steel strip unwinding device 1 is used to install the steel strip coil and unwind the steel strip coil. The unwinding coil is flattened by the steel strip flattening device 2 and then transported to the steel strip hemming device 3 . The steel strip hemming device 3 gradually presses the two side edges of the flattened steel strip into right-angled secondary bending edges, and the steel strip closing device 4 ...

Embodiment 2

[0058] This embodiment provides a high-efficiency grinding-free automatic tube-making method suitable for the high-efficiency grinding-free automatic tube-making machine of Embodiment 1, including the following steps:

[0059]S1, the steel strip unwinding device 1 unwinds the steel strip, and the unrolled steel strip enters between the two horizontal rollers of the steel strip flattening device 2 for flattening;

[0060] S2. The flattened steel strip is pressed into a right-angled secondary hemming by the steel strip hemming device 3 on both sides of the steel strip; the secondary hemming has two 90-degree bending angles and two pieces are connected and basically A plane bent at 90 degrees. The secondary fold is first bent 90 degrees upward from the center outward, and then bent outward 90 degrees horizontally.

[0061] S3, the horizontal roller press 41 of the steel strip closing device 4 presses the middle part of the steel strip so that the middle part of the steel strip i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com