Digital occlusal adjustment guide and manufacturing method thereof

A manufacturing method and technology of occlusal splints, applied in the field of tooth restoration, can solve problems such as inability to realize entity and digitization, achieve good restoration effects, reduce clinical operation time, and reduce irregularities and inaccuracies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

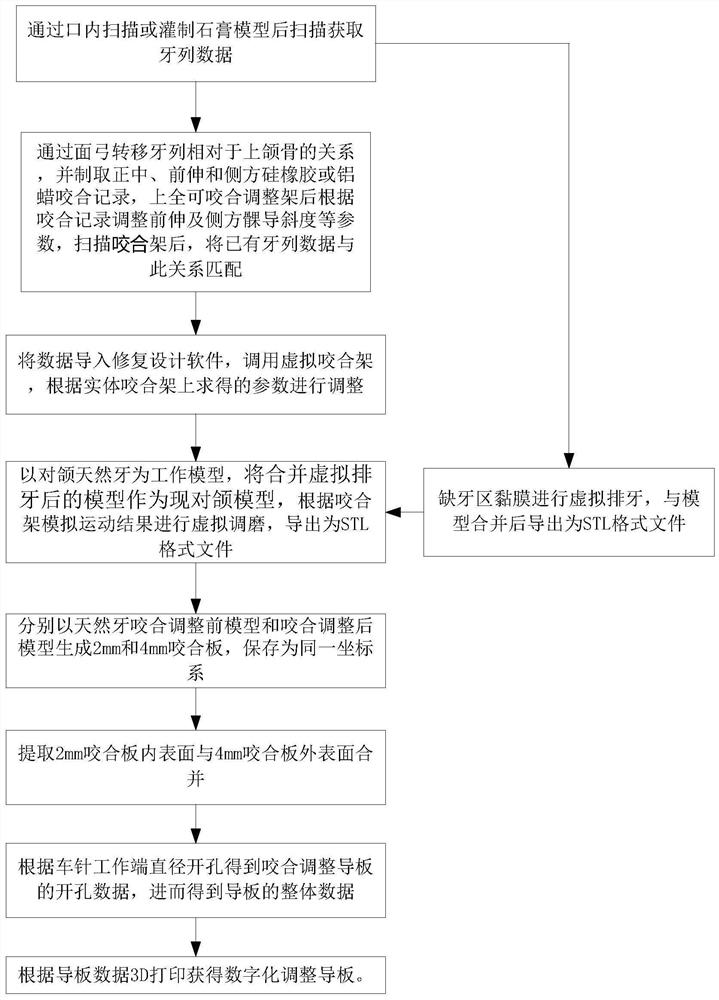

[0046] A method for manufacturing a digital occlusal adjustment guide plate includes the following steps:

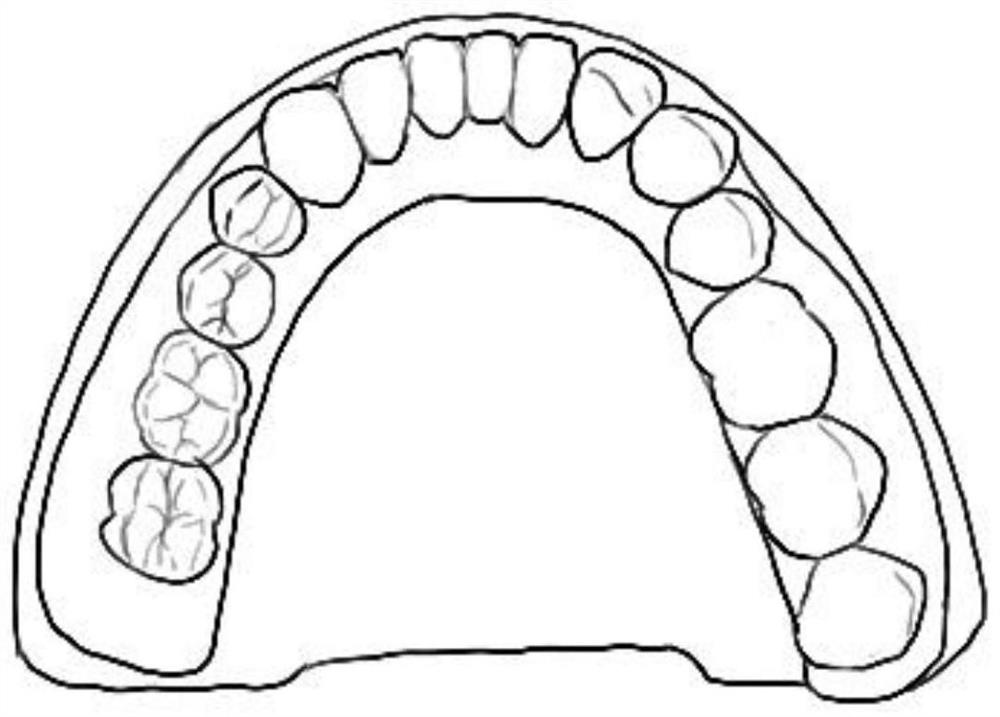

[0047] Step S1: Intraoral scan to obtain dentition data, including upper and lower dentition data and partial gingival morphology, and obtain a preoperative model based on dentition data;

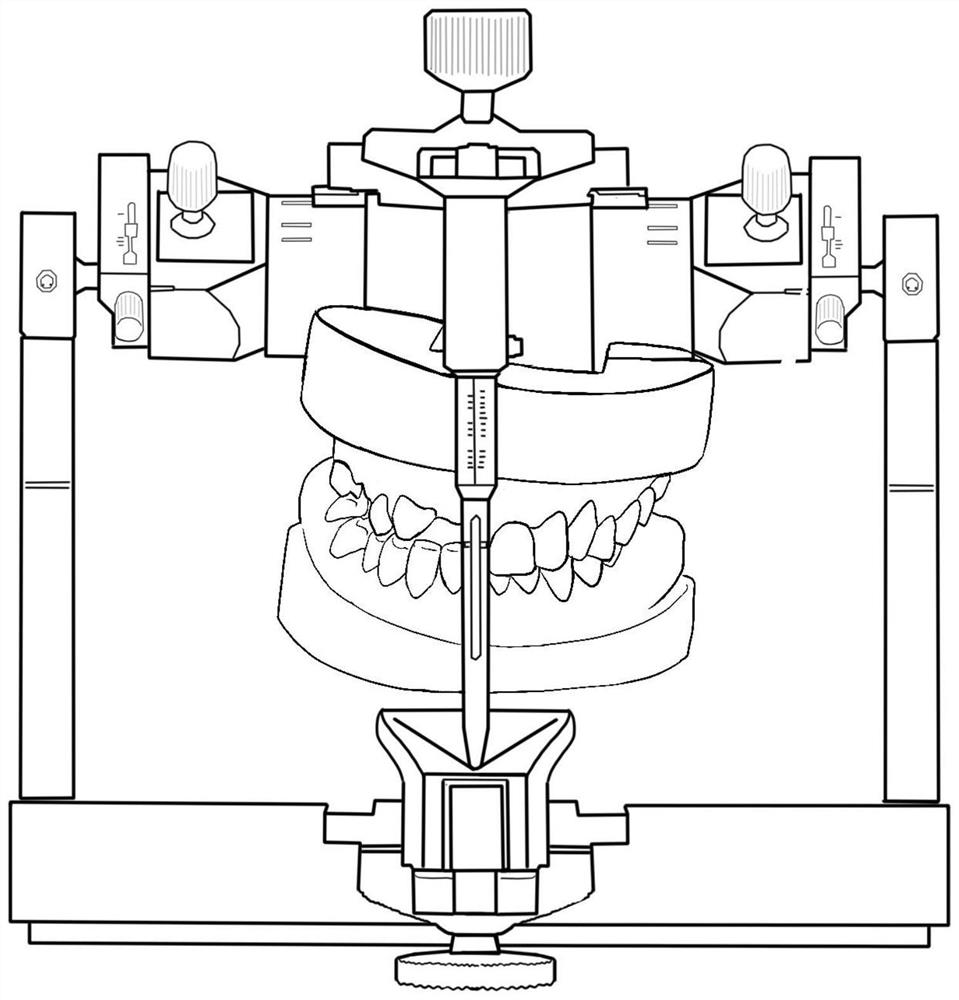

[0048] Step S2: Record the positional relationship of the maxillary dentition relative to the maxillary bone through the facebow, fix the occlusal plate recording the positional relationship on the transfer table through the universal joint, and fix the maxillary dentition model in a fully adjustable occlusion through the transfer table On the frame, the reference plane of the facebow is the same as the reference plane of the fully adjustable articulator; the mandibular dentition model is reset and fixed on the articulator by using the central position relationship of the prepared upper and lower dentition; Extension and lateral occlusal records Adjust the forward extension and latera...

Embodiment 2

[0063] The difference between this embodiment and Embodiment 1 is that in the step S1, a super-anhydrite model is cast after taking a traditional impression, and the scanned model is used as a preoperative model.

Embodiment 3

[0065] The difference between this embodiment and Embodiment 1 is that the implementation of step S7 is different:

[0066] Generate a 4mm thick occlusal plate based on the model after occlusal adjustment, and subtract the model before occlusal adjustment by Boolean operation to generate the prototype of the guide plate; or select a range on the model before occlusal adjustment, use the offset tool to offset 2mm, and Flip the normal direction, select the occlusal adjustment range on the occlusion-adjusted model, use the offset tool to offset 4mm, merge the offset patches and fill the holes to complete the occlusal adjustment guide plate prototype.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com