Manufacturing method of power battery, power battery and automobile

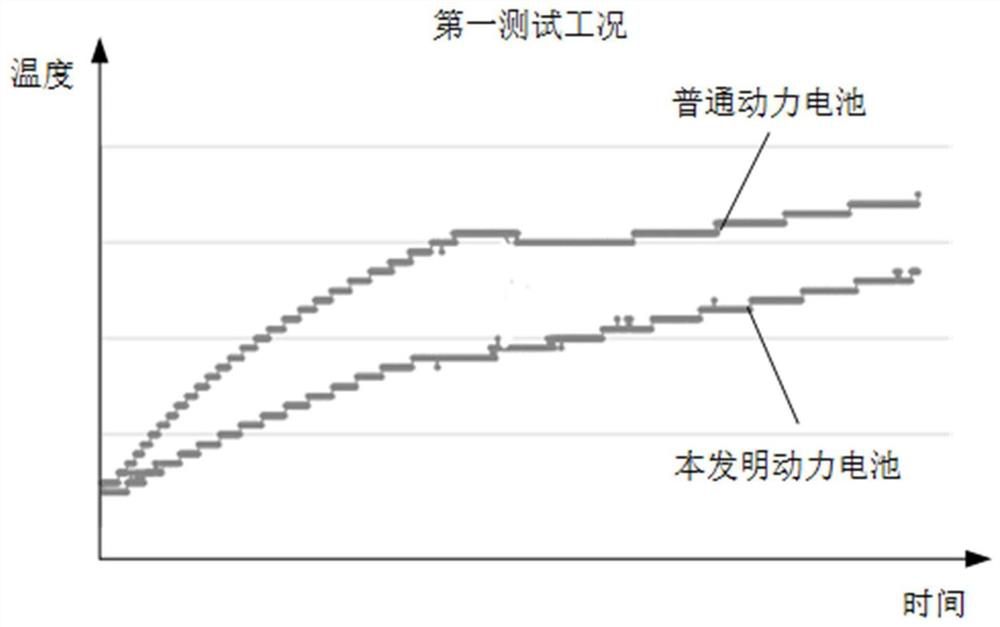

A power battery and manufacturing method technology, which is applied in the direction of batteries, secondary batteries, battery pack components, etc., can solve the problems of shortened battery life, consistency deviation, battery temperature rise, etc., to ensure reliability and safety, The effect of effective heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

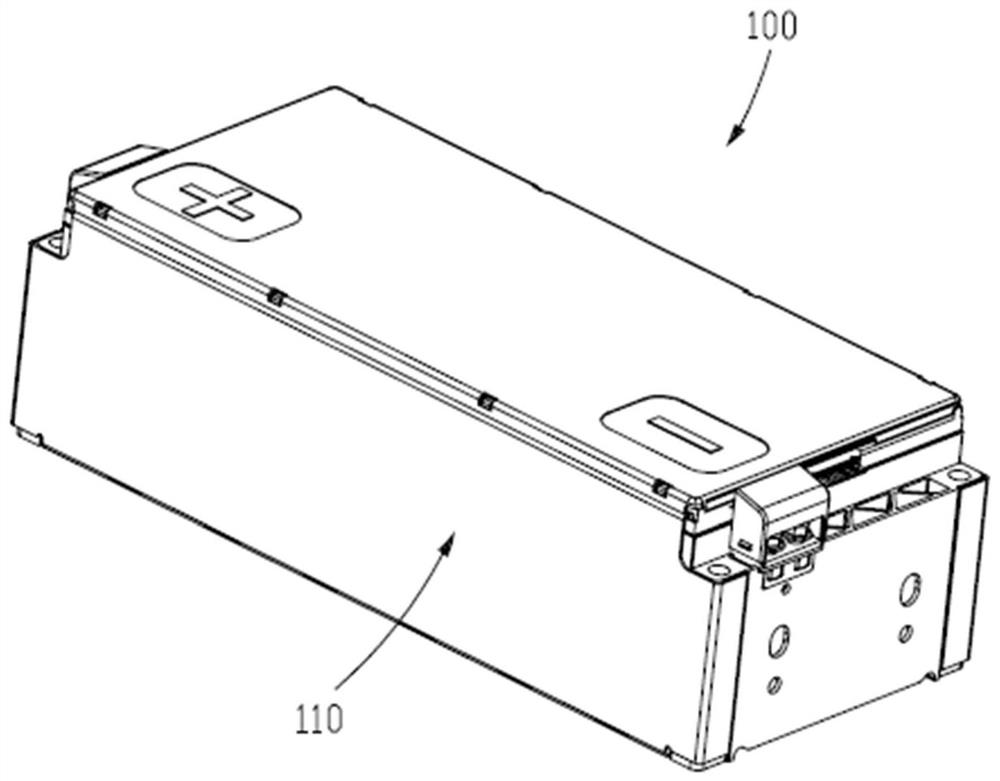

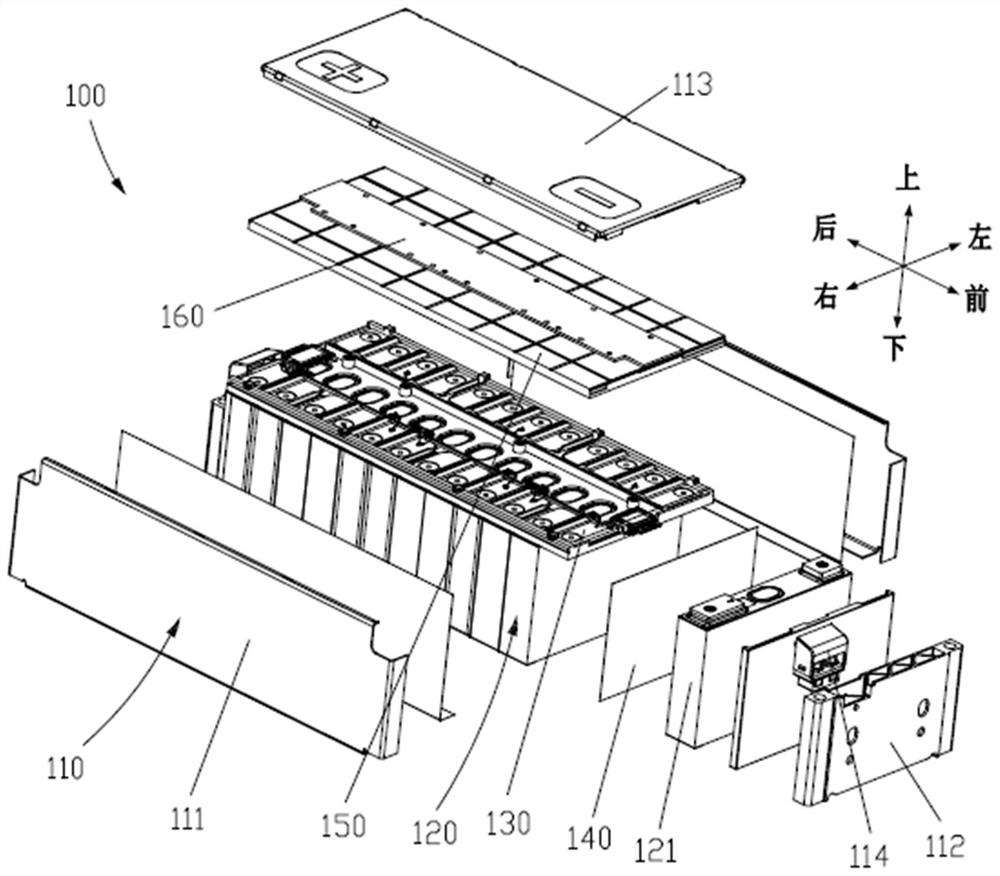

[0053] An embodiment of the present invention provides a power battery, such as figure 1 and figure 2As shown, the power battery includes a battery module 100, and also includes a cooling medium heat dissipation unit (not shown in the figure). The cooling medium heat dissipation unit can adopt existing cooling methods such as air cooling, liquid cooling, and direct cooling. A cooling medium heat dissipation unit is integrated to dissipate heat for the battery module 100 , so the cooling medium heat dissipation unit in the present invention can directly use the original cooling medium heat dissipation unit of the power battery.

[0054] Please combine figure 1 and figure 2 The battery module 100 includes a casing 110, a battery cell 120, and a busbar 130. The battery cell 120 includes a plurality of single cells 121 arranged in sequence along a first direction, and the plurality of single cells 121 are assembled into one battery cell 120 such that The battery cell 120 can ...

Embodiment 2

[0064] The embodiment of the present invention also provides a method for manufacturing a power battery, the manufacturing method is used to manufacture the above-mentioned power battery, Figure 7 It is a block flow diagram of the manufacturing method of the power battery in the embodiment of the present invention, such as Figure 7 As shown, the manufacturing method includes the steps of:

[0065] S100, determining the physical parameters of the phase change material layer 140 and the thermally conductive potting adhesive layer 150;

[0066] Specifically, it is determined here that the physical parameters of the phase-change material layer 140 and the heat-conducting potting compound layer 150 can be estimated based on experience, and then the corresponding phase-change material and heat-conducting potting compound are selected according to the estimated physical parameters, and then through simulation experiments and Calculate to judge whether the phase change material and...

Embodiment 3

[0097] The embodiment of the present invention also provides an automobile, which includes the power battery as described above. Since the automobile of the present invention adopts the power battery of the present invention, it has at least the beneficial effects of the power battery of the present invention, and will not be repeated here. repeat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com