Method for optimizing track of complex revolved body and system

A trajectory optimization and rotary body technology, applied in the field of material manufacturing, can solve problems such as unsatisfactory comprehensive mechanical properties of components and difficult structure to meet design requirements, and achieve the effect of improving comprehensive mechanical properties and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

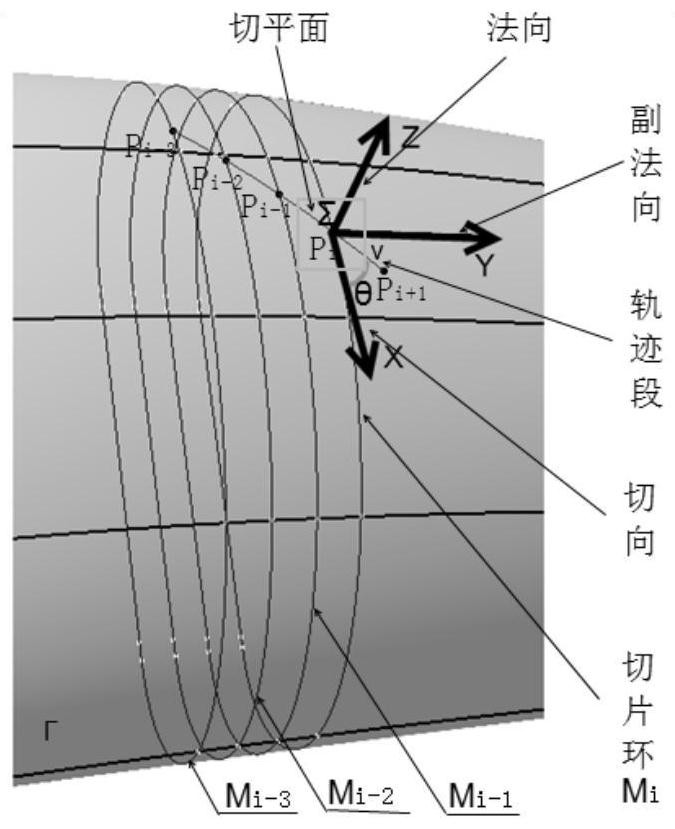

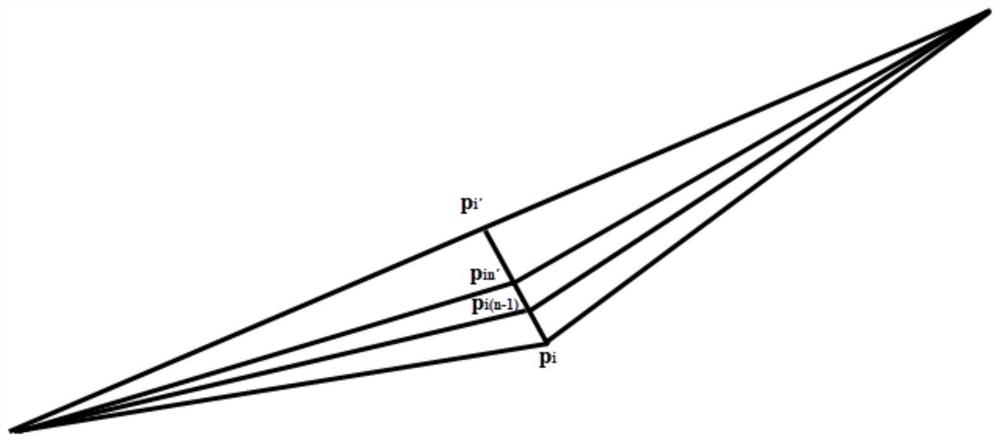

[0024] The invention generates an initial track according to the component laying angle and material curvature requirements, and then adopts an equidistant offset to generate an offset track. Because it is difficult to guarantee the trajectory curvature requirements and angle deviation of the offset trajectory, the present invention adopts an automatic wire laying path optimization method using local adjustment and global optimization. The method of the invention makes full use of the variable curvature algorithm to generate the initial trajectory, takes into account the requirements of structural design and silk laying process, and at the same time fully utilizes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com