Asphalt pavement crack embedded repairing method

An asphalt pavement and embedded technology, applied in the field of asphalt pavement construction, can solve problems such as low strength and secondary cracking, and achieve the effects of improving repair strength, preventing secondary cracking, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

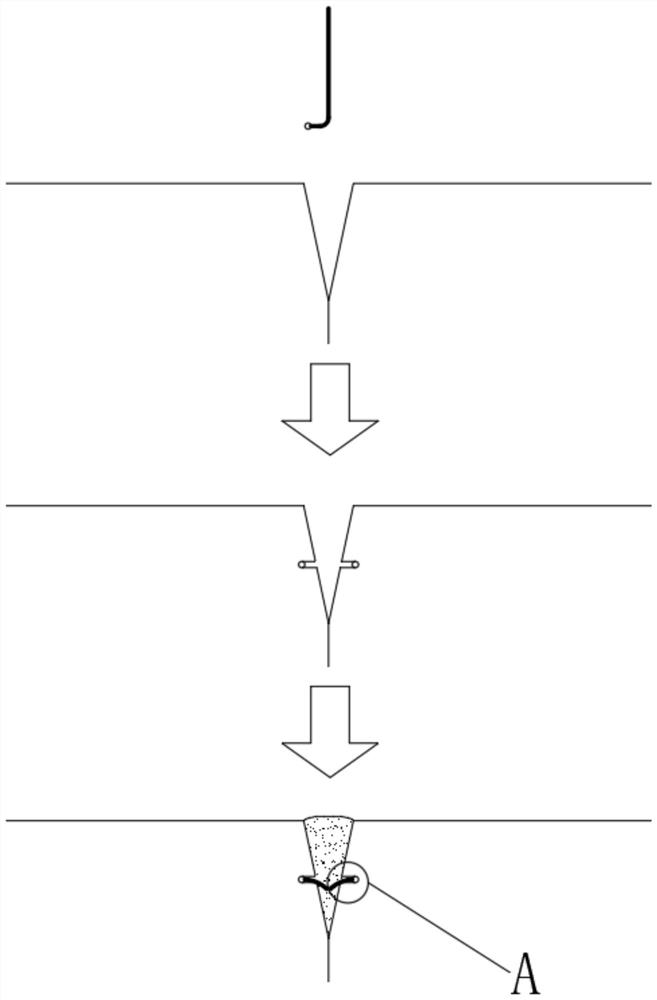

[0043] see Figure 1-2 , an embedded repair method for asphalt pavement cracks, comprising the following steps:

[0044] S1. Determine the size of the slot according to the size of the crack, and expand the slot through the slotting machine, and the width is not less than 1cm;

[0045] S2. First, use a high-power blower or hot air gun to blow out the sundries in the seam for 1-2 times, and then use a special hook to clean a small amount of debris and sundries in the groove. Manual cleaning, after cleaning, blow it again to ensure that the seam is absolutely dry and clean;

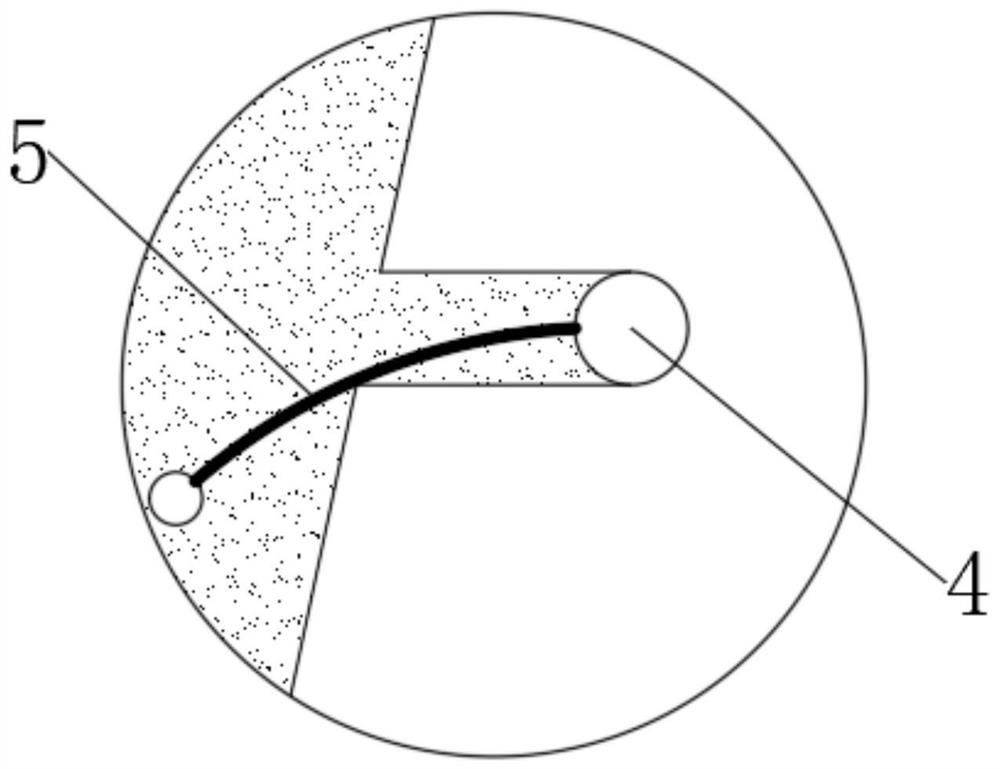

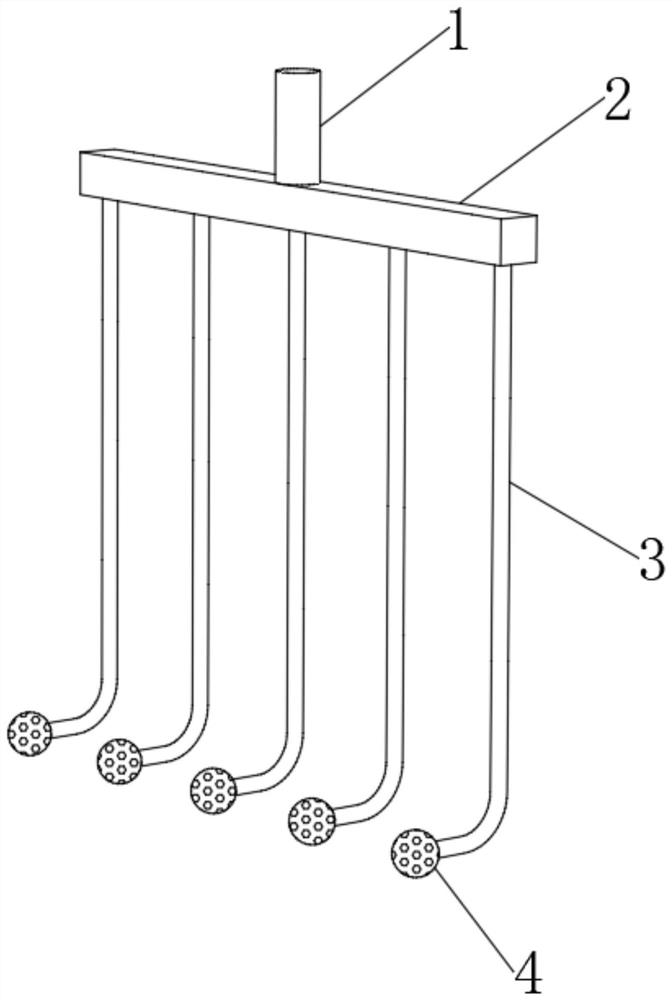

[0046] S3. Use the embedding tool to evenly excavate a plurality of fusion embedding holes through the molten asphalt on the two side walls of the crack, and reserve the pre-embedded magnetic suction ball 4 in the fusion embedding holes, and pull out the embedding holes after the asphalt is cooled and solidified tool;

[0047] S4. The seam filling material is prepared on site and mixed with an appropriat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com