Online real-time monitoring treatment system for printing and dyeing sewage treatment

A technology for real-time monitoring, printing and dyeing of sewage, applied in the direction of water/sewage treatment, degassed water/sewage treatment, water/sewage treatment equipment, etc., can solve secondary pollution, harmful to human health, and cannot be classified into solid impurities and liquid impurities and other issues to achieve better results and avoid rigid impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in a variety of different ways defined and covered by the claims.

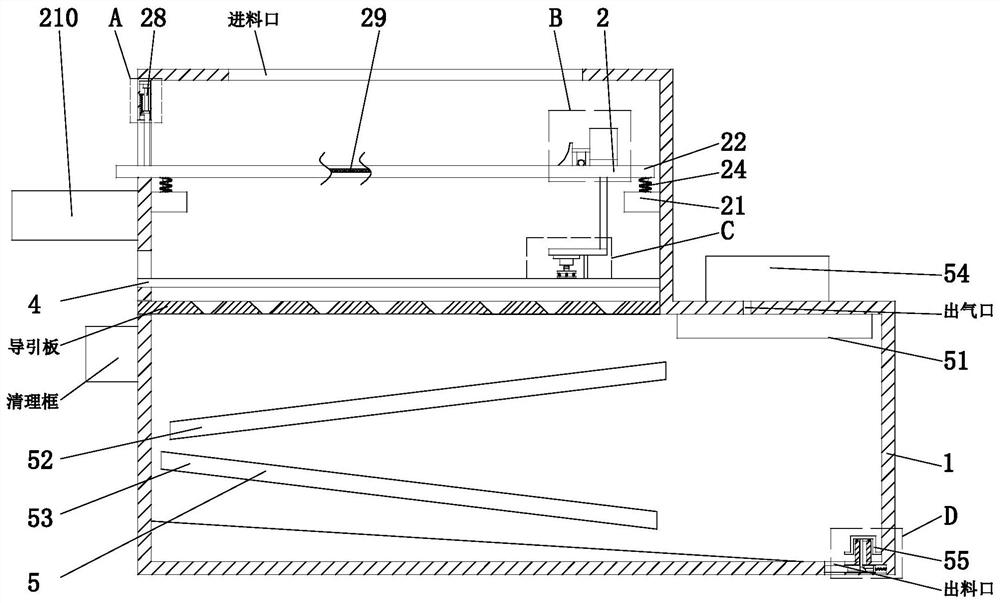

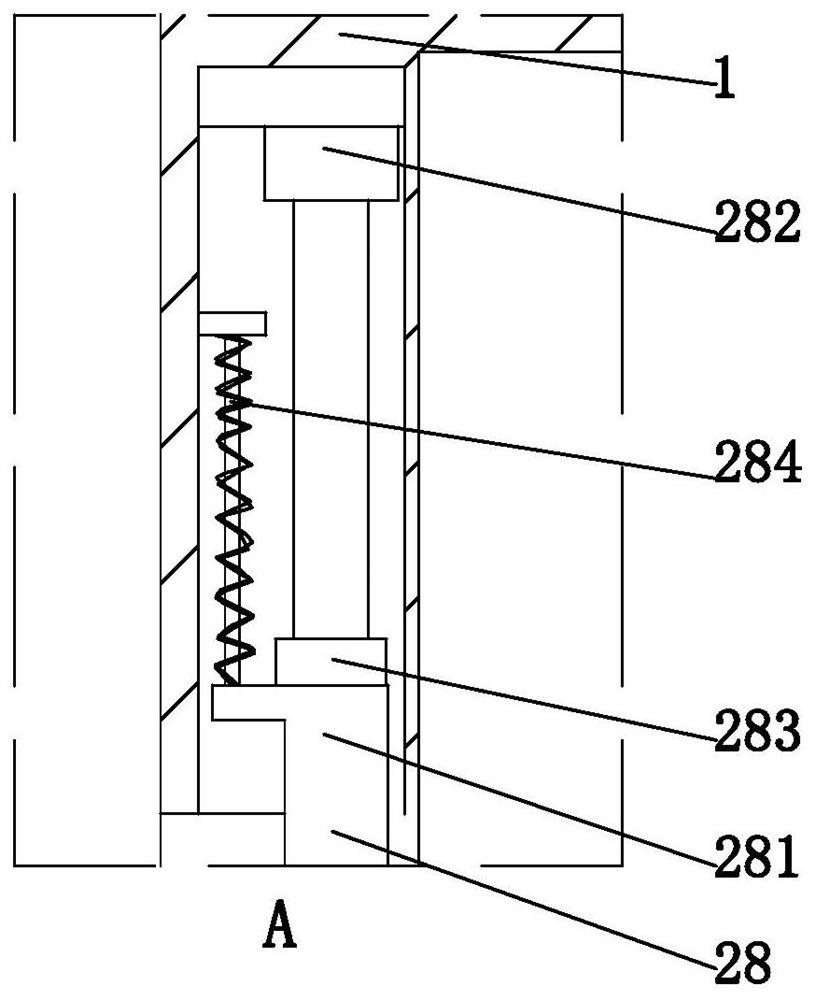

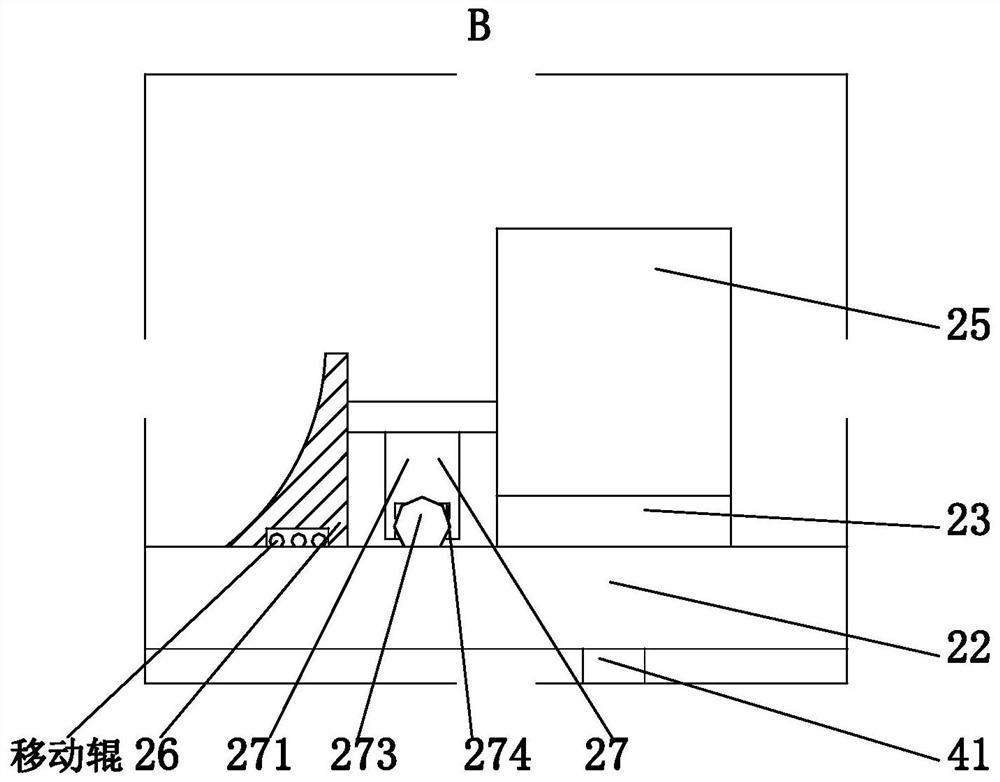

[0035]Such asFigure 1 to Figure 9As shown, an online real-time monitoring and processing system for printing and dyeing sewage treatment includes a processing box 1, a pretreatment mechanism 2, a cleaning mechanism 4, a reprocessing mechanism 5, and a central control mechanism. The processing box 1 has a stepped structure. 1 There is a feed port on the left side of the upper end surface, an air outlet is provided on the right side of the upper end surface of the processing box 1, a discharge port is provided on the lower end surface of the processing box 1, and a pretreatment mechanism 2 is installed on the inner wall of the processing box 1 under the discharge port. The inner wall of the processing box 1 is located below the pre-processing mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com