A Surface Damage Repair Device for Lightweight and High-Strength Parts Based on Friction Stir Method

A technology of friction stir and damage repair, which is applied in the direction of metal processing equipment, welding equipment, manufacturing tools, etc., can solve problems such as thermal cracks, shrinkage cavities, and no obvious repair effect, so as to increase the area, avoid the keyhole treatment process, The effect of improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

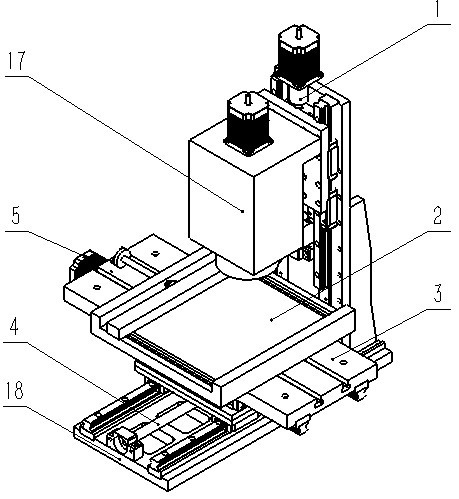

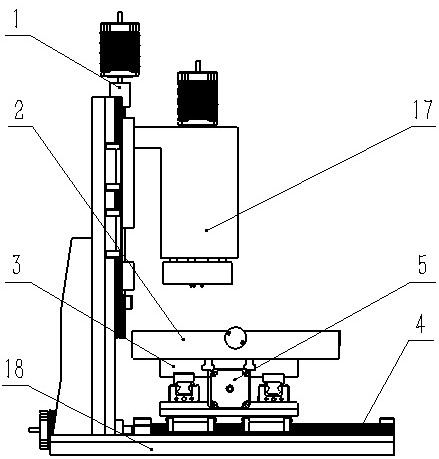

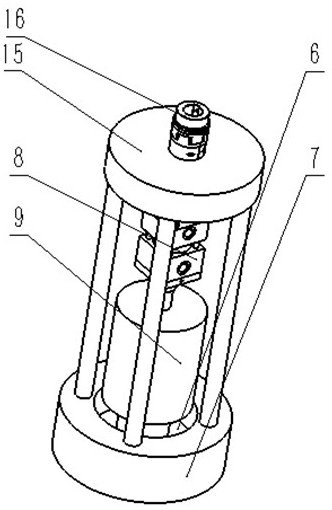

[0027] A device for repairing surface damage of lightweight and high-strength parts based on friction stir method, such as figure 1 , 2 As shown, it includes an L-shaped support 18, a first feed mechanism 1, a workbench 3, a clamping member 2, a second feed mechanism 4, a third feed mechanism 5, a motor, a friction stirring keyhole removal mechanism 17 and a joint Shaft device 16. The L-shaped bracket 18 includes a connected vertical plate and a horizontal plate, and the vertical plate is fixedly connected to the first feeding mechanism 1 by bolts, and the horizontal plate is fixedly connected to the second feeding mechanism 4 by bolts. Described first feeding mechanism 1 comprises the screw mandrel that is fixedly arranged on the vertical plate of support 18, and described screw mandrel is socketed with the axle sleeve of guide rail, and lead screw is connected with motor by shaft coupling, and described axle sleeve and stirring The protective shell of the friction keyhole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com