A kind of liquid metal cooling directional solidification casting and measuring method of shell temperature

A liquid metal cooling and directional solidification technology, applied in thermometers, measuring heat, measuring devices, etc., can solve problems such as shell cracks, increase the impact of temperature changes, and short-circuit thermocouples, so as to achieve the effect of not being prone to cracks and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

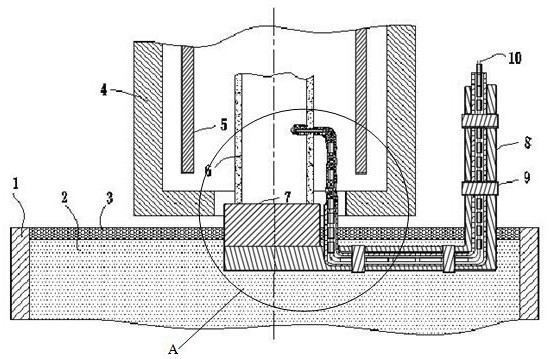

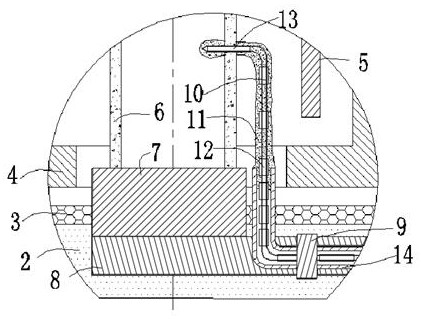

[0025] Referring to the accompanying drawings, a liquid metal cooling directional solidification casting and mold shell, including liquid metal container for cooling (1), liquid metal for cooling (2), floating heat insulation baffle (3), holding furnace (4), graphite Heating body (5), ceramic shell (6), chilling plate (7), bracket (8), pipe collar (9), thermocouple (10), ceramic slurry and refractory aggregate protective layer (11) , the first ceramic insulating section (12), the second ceramic insulating section (13), the molded ceramic protection tube (14), the cooling liquid metal (2) is set in the cooling liquid metal container (1), and the cooling liquid metal A floating heat insulation baffle (3) is arranged on the metal container (1) and the cooling liquid metal (2), and a chilling plate (7) and a bracket (8) are arranged in the cooling liquid metal container (1). A ceramic shell (6) is set on the cold plate (7), a holding furnace (4) is set on the outer circumference o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com