Release agent for casting storage battery grid and preparation method thereof

A battery and release agent technology, applied in the direction of casting molding equipment, molds, mold components, etc., can solve the problems of high temperature resistance of the release agent, increased production costs, poor adhesion of the release agent, etc., to reduce production cost, increase production efficiency, and improve the effect of grid quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

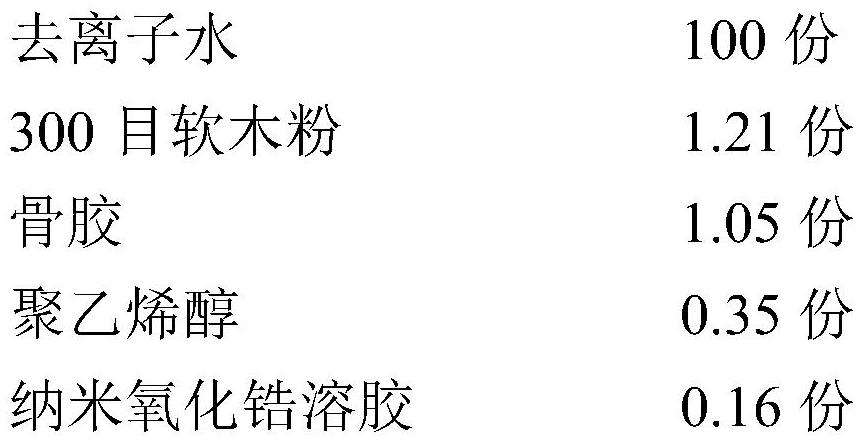

[0031] 1. Raw materials

[0032]

[0033] 2. Preparation method

[0034] Mix the measured deionized water, bone glue and polyvinyl alcohol, and stir the mixture with a stirrer at a stirring speed of 500r / min. Stir continuously during the heating process until it boils, stop heating and continue stirring until the temperature drops to 50 Heat to boiling again at ℃, and continue to stir for 15 minutes to completely dissolve the bone glue and polyvinyl alcohol; add the measured nano-zirconia sol, mix and stir evenly, and stir at a speed of 400r / min, and heat to boiling after stirring for 5 minutes; add The measured cork powder is stirred at a speed of 550 r / min, heated to boiling and stirred again for 10 minutes until the mixed solution and cork powder are completely stirred until uniformly dispersed, and the mold release agent is obtained after cooling.

[0035] 3. Analysis of results

[0036] Spray the prepared release agent evenly on the grid casting mold, and perform gri...

Embodiment 2

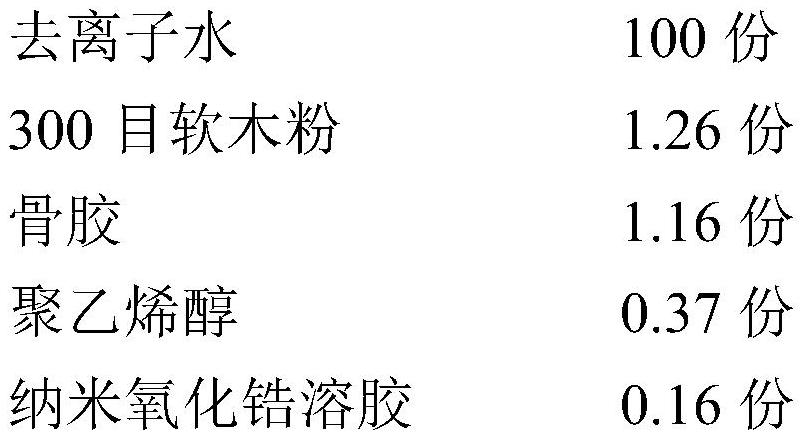

[0038] 1. Raw materials:

[0039]

[0040] 2. Preparation method

[0041] Mix the measured deionized water, bone glue and polyvinyl alcohol, and stir the mixture with a stirrer at a stirring speed of 450r / min. Stir continuously during the heating process until it boils, stop heating and continue stirring until the temperature drops to 50 Heat to boiling again at ℃, and continue to stir for 15 minutes to completely dissolve the bone glue and polyvinyl alcohol; add the measured nano-zirconia sol, mix and stir evenly, and stir at a speed of 450r / min, and heat to boiling after stirring for 5 minutes; add The measured cork powder is stirred at a speed of 500r / min, heated to boiling and stirred again for 10 minutes until the mixed solution and cork powder are completely stirred until evenly dispersed, and cooled for later use.

[0042] 3. Analysis of results

[0043] Spray the prepared mold release agent evenly on the grid casting mold, and perform grid casting. The model of th...

Embodiment 3

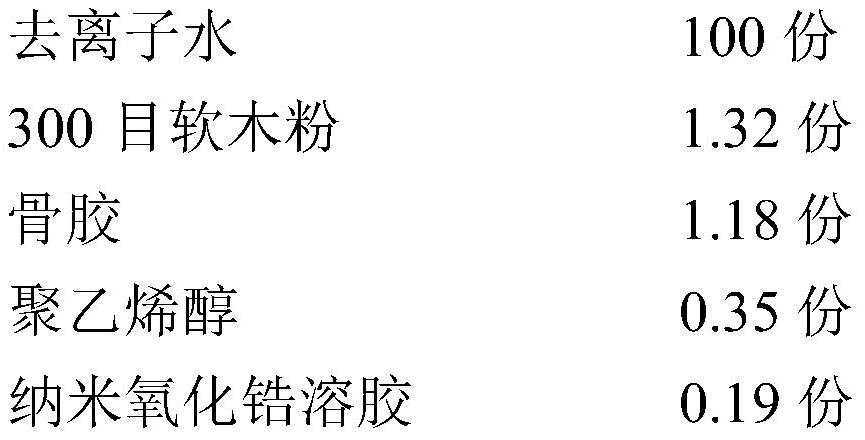

[0045] 1. Raw materials:

[0046]

[0047] 2. Preparation method

[0048] Mix the measured deionized water, bone glue and polyvinyl alcohol, and stir the mixture with a stirrer at a stirring speed of 480r / min. Stir continuously during the heating process until it boils, stop heating and continue stirring until the temperature drops to 50 Heat to boiling again at ℃, and continue to stir for 18 minutes to completely dissolve the bone glue and polyvinyl alcohol; add the measured nano-zirconia sol, mix and stir evenly, and stir at a speed of 400r / min, and heat to boiling after stirring for 5 minutes; add The measured cork powder is stirred at a speed of 550 r / min, heated to boiling and stirred again for 10 minutes until the mixed solution and the cork powder are completely stirred evenly, and the release agent is obtained after cooling.

[0049] 3. Analysis of results

[0050]Spray the prepared mold release agent evenly on the grid casting mold, and perform grid casting. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com