Crushing and sorting equipment for waste building structure

A structure and sorting technology, which is applied in magnetic separation, solid separation, grain processing, etc., can solve the problems of difficult metal material sorting, poor sorting effect, damage to crushing rollers, etc., to achieve convenient use and improve the sorting effect , functional and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

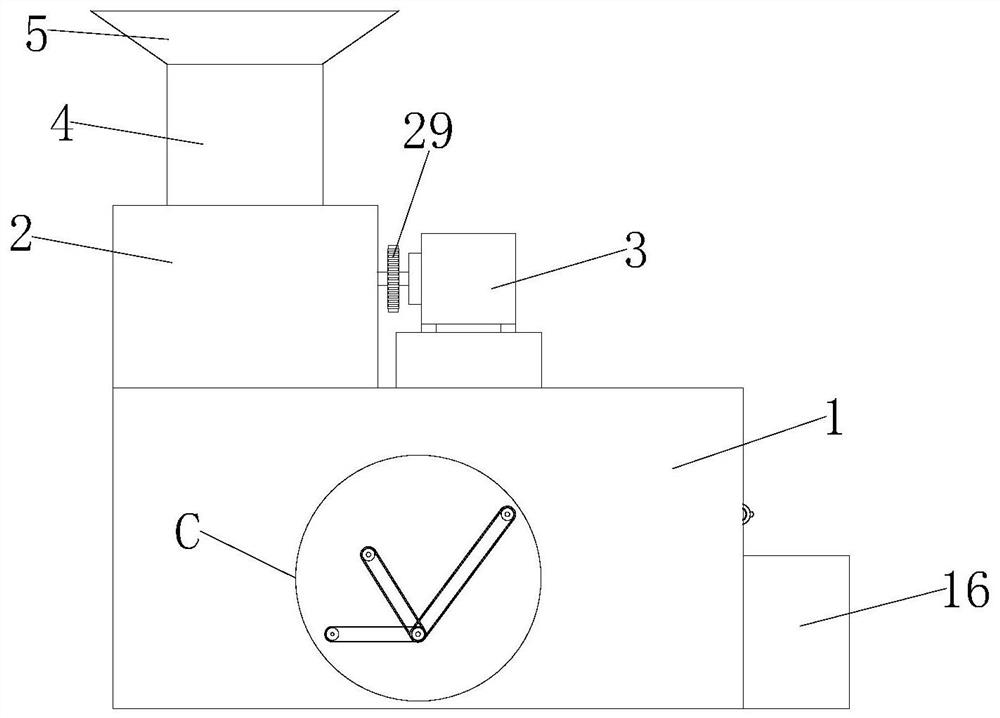

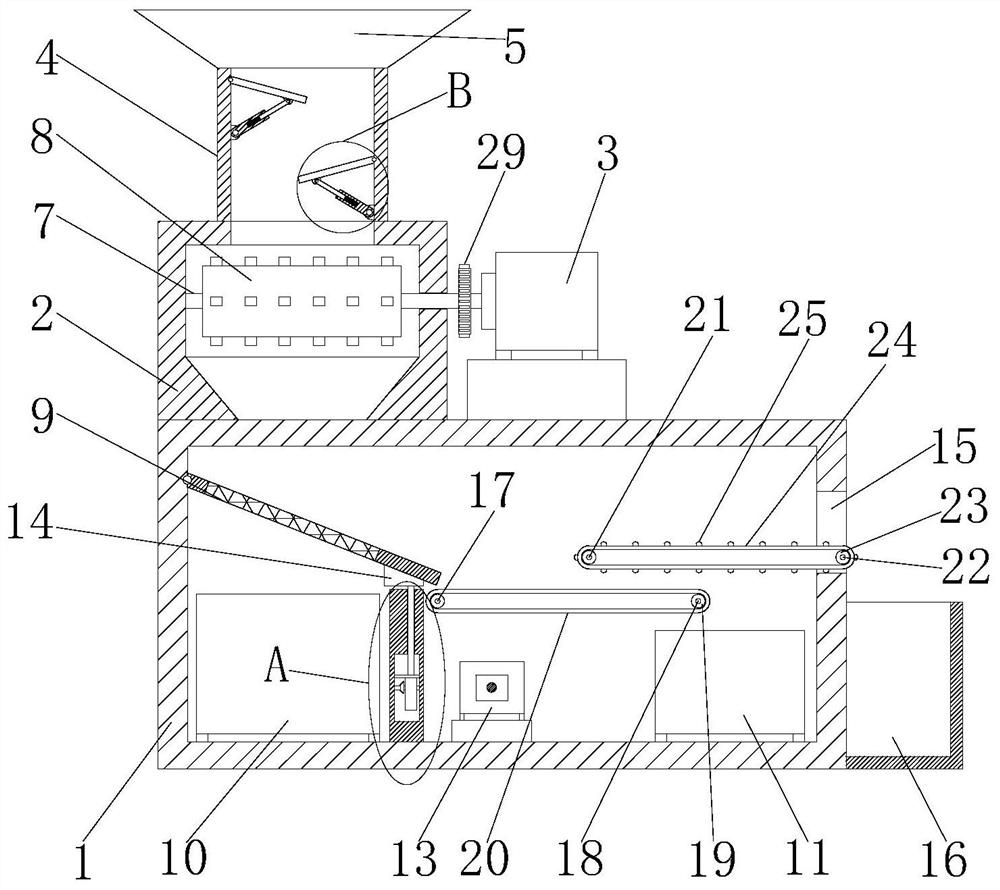

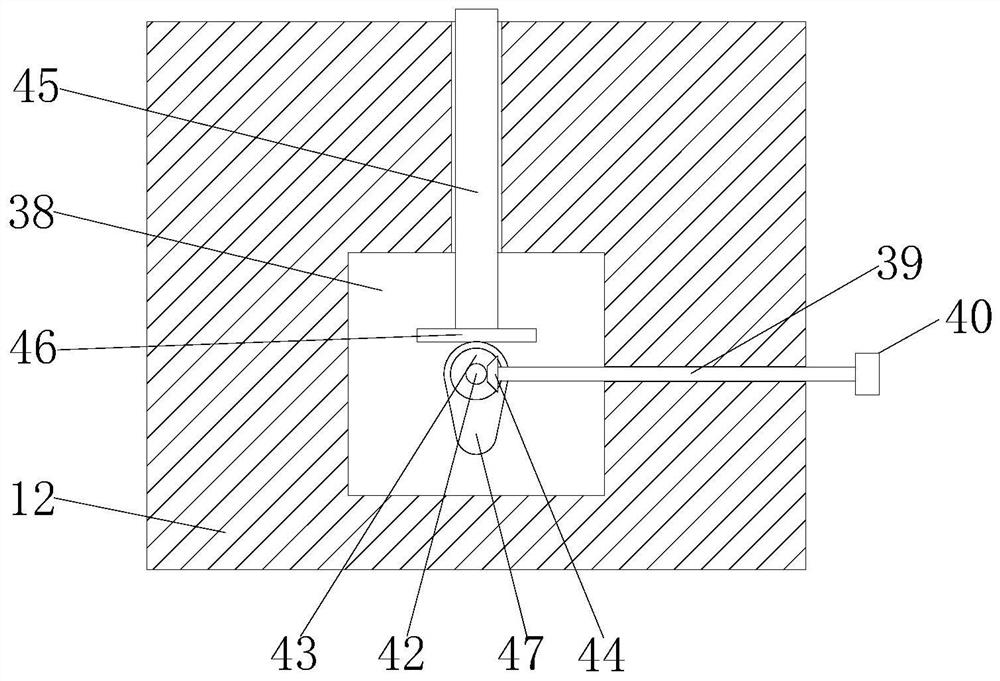

[0031] refer to Figure 1-7 , a crushing and sorting equipment for abandoned building structures, comprising a first housing 1, the top of the first housing 1 is fixedly connected with a second housing 2, the top of the first housing 1 and the bottom of the second housing 2 Connected, the top of the first housing 1 is fixedly installed with the first motor 3, the top of the second housing 2 is connected with the buffer channel 4, the top of the buffer channel 4 is fixedly connected with the feed hopper 5, the buffer channel 4 Buffer plates 6 are connected on the inner walls of both sides, and two rotating shafts 7 are installed in rotation in the second housing 2, and crushing rollers 8 are fixedly sleeved on the outer sides of the two rotating shafts 7, and the two crushing rollers 8 are connected with the first A motor 3 cooperates, the left inner wall of the first housing 1 is hinged with a filter screen 9, and the bottom inner wall of the first housing 1 is fixedly connect...

Embodiment 2

[0042] refer to Figure 1-7 , a crushing and sorting equipment for abandoned building structures, comprising a first shell 1, the top of the first shell 1 is fixedly connected with a second shell 2 by welding, the top of the first shell 1 is connected with the second shell 2 The bottom of the first housing 1 is connected with the first motor 3 by bolts, the top of the second housing 2 is connected with a buffer channel 4, and the top of the buffer channel 4 is fixedly connected with a feed hopper by welding 5. Buffer plates 6 are attached to the inner walls of both sides of the buffer channel 4, and two rotating shafts 7 are installed in the second housing 2, and the outer sides of the two rotating shafts 7 are equipped with crushing rollers 8 through welding and fixing sleeves. The two crushing rollers 8 are all matched with the first motor 3, the filter screen plate 9 is hinged on the left inner wall of the first housing 1, and the first collecting box 10, the second collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com