Semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, which are applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problem that the cathode and the auxiliary cathode cannot be well overlapped, so as to avoid uneven light emission, reduce the width, and improve the The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

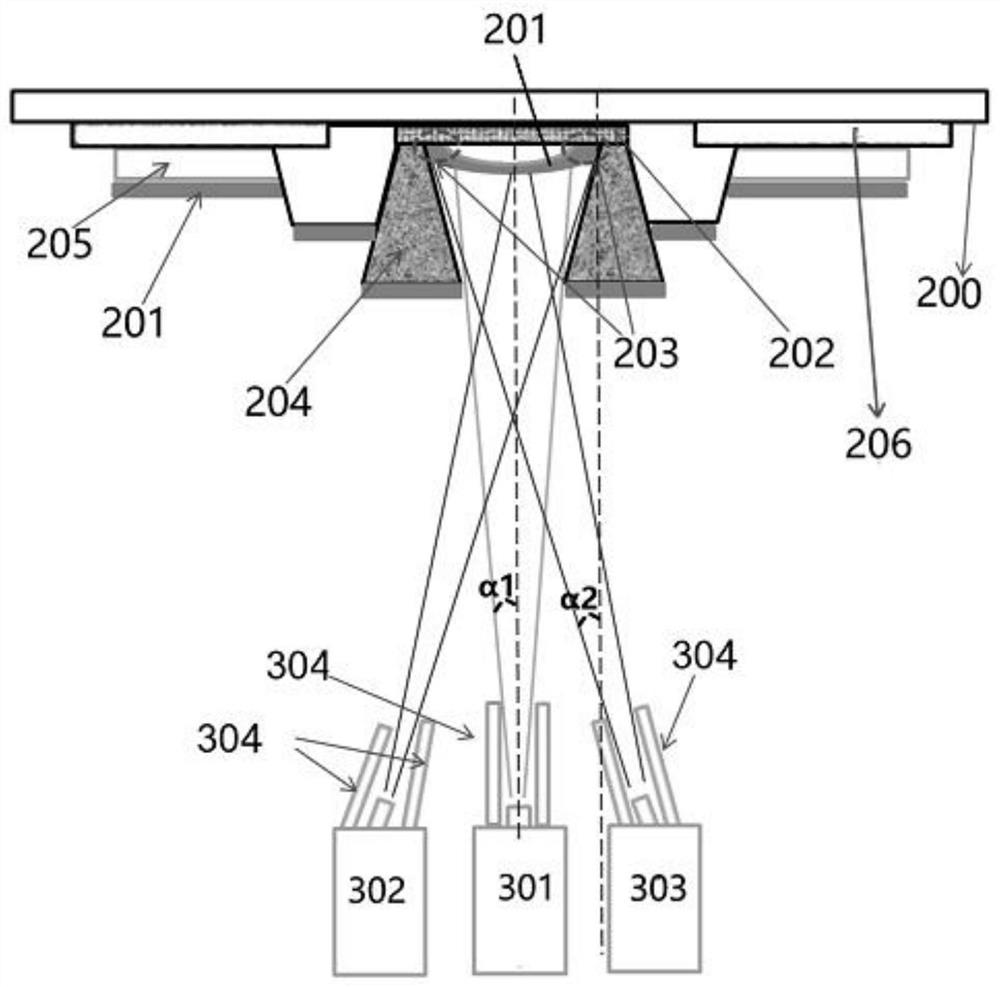

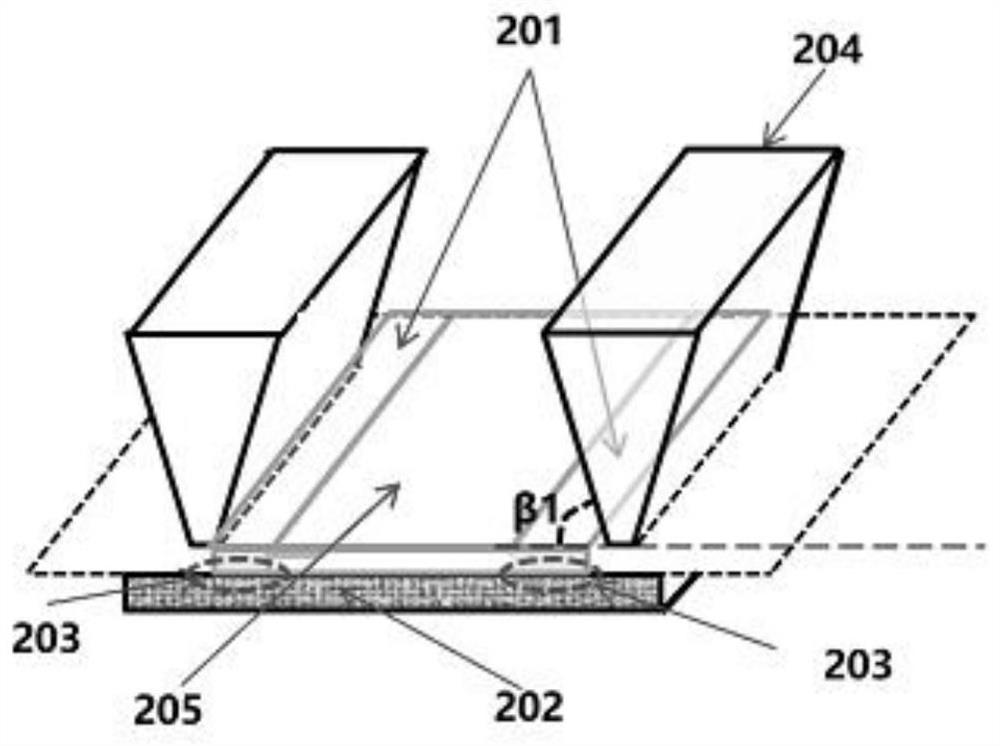

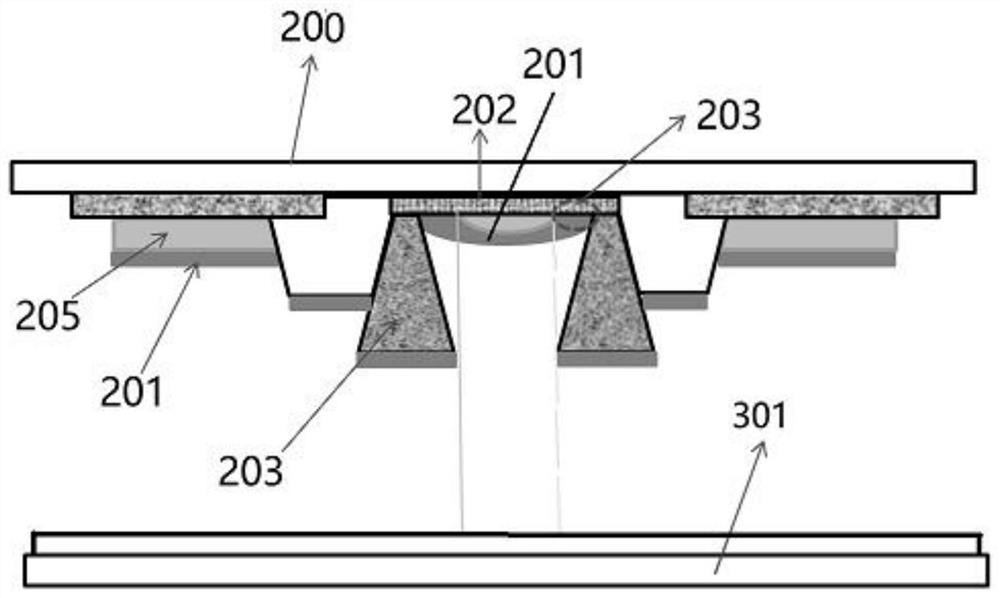

[0052] see Figure 1 to Figure 4 , the present embodiment provides a method for manufacturing a semiconductor device, including the following steps: making an auxiliary cathode 202 on a substrate 200; specifically, coating a layer of photoresist on the substrate 200, patterning the photoresist, that is, exposing and developing the photoresist , so that the part where the auxiliary cathode 202 is to be made is opened. The auxiliary cathode material is plated by evaporation to form an auxiliary cathode 202 on the substrate 200, with a structure such as figure 1 shown. Wherein, the auxiliary cathode material may be one or more metals among Al (aluminum), Ag (silver), and Au (gold). The thickness of the auxiliary cathode 202 is 1 um (m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com