A deduction method for magnetorheological polishing removal function based on curvature and immersion depth

A technology of magnetorheological polishing and immersion depth, which is applied in special data processing applications, geometric CAD, design optimization/simulation, etc. It can solve problems such as high cost, low efficiency, and complex removal function modeling process to reduce model accuracy The effect of ensuring the solution efficiency and solving the effect of large errors in the geometric model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The present embodiment provides a magnetorheological polishing removal function deduction method under the curvature effect, and the specific steps are:

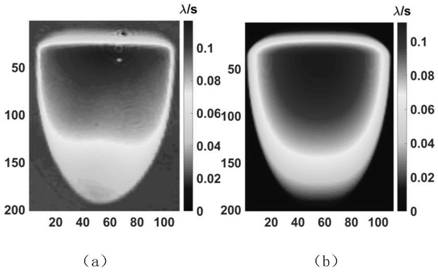

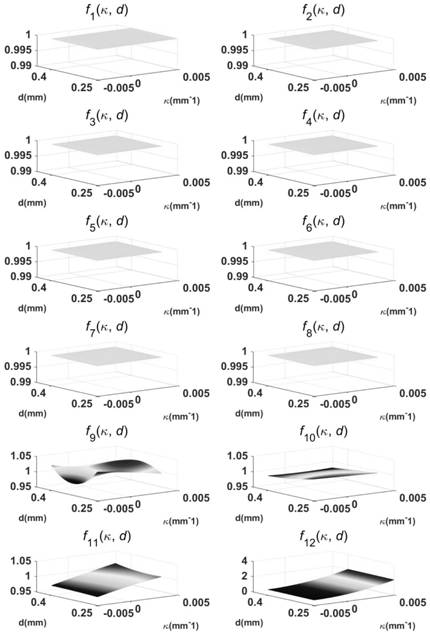

[0052] Step 1, under certain process parameters, collect polishing spots with different immersion depths on the plane and spherical mirrors with different curvatures, and obtain the experimental removal function. Specifically, the immersion depth range is 0.25mm to 0.4mm, the curvature of the convex spherical surface is negative, the curvature of the concave spherical surface is positive, and the curvature range is -1 / 200mm -1 to 1 / 200mm -1 , each polishing spot is denoted as R mn , where m=0…6, n=0…2, a total of 21 spots were collected. The experimental specimens and spot sampling parameters are shown in Table 1:

[0053] Table 1: Experimental Specimen and Spotting Parameter Information

[0054]

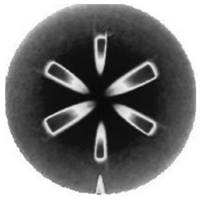

[0055] The spot picking method is the normal circular spot picking method, such as figure 1 As shown, the figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com