Metal plate stress detection method based on electromagnetic ultrasonic Lamb wave S1 modal group velocity

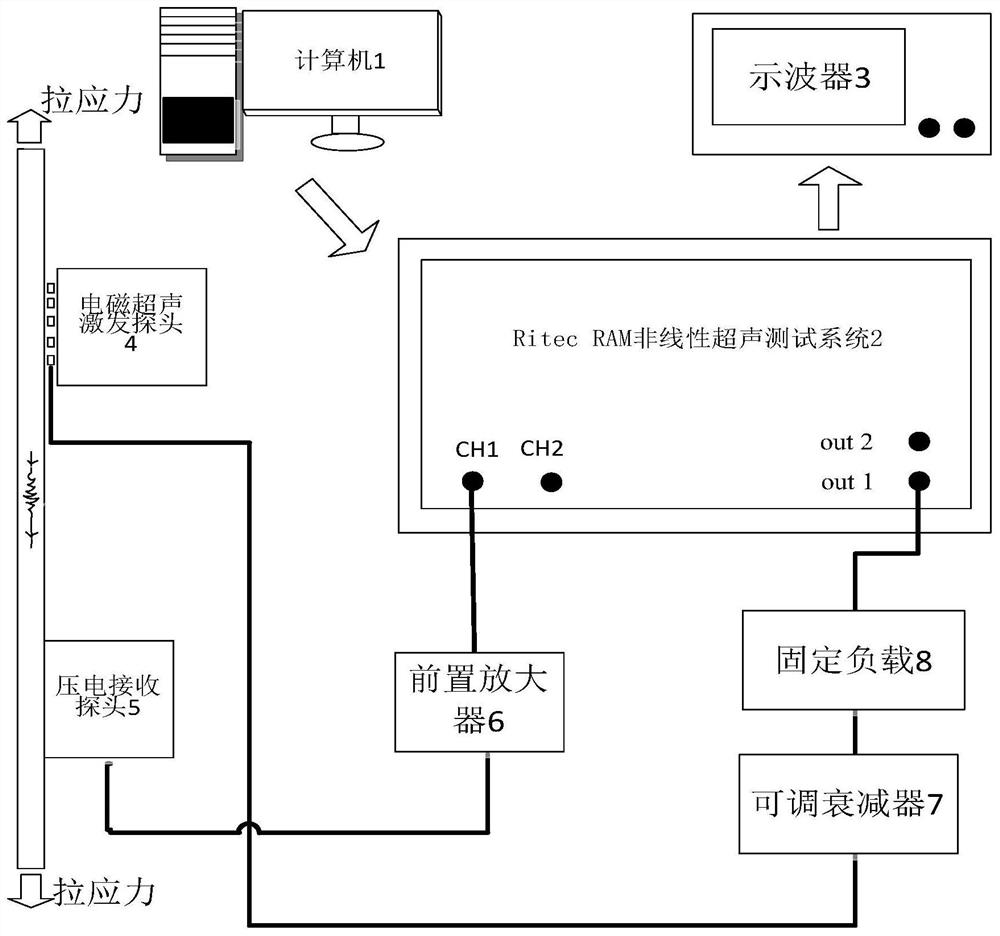

An electromagnetic ultrasonic and stress detection technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and measuring devices, etc. It can solve the problem of low Lamb wave velocity test accuracy and difficult extraction of waveform modes. and separation, complex Lamb wave signals, etc., to achieve the effect of increasing the rate of change of velocity, obvious amplitude, and easy use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

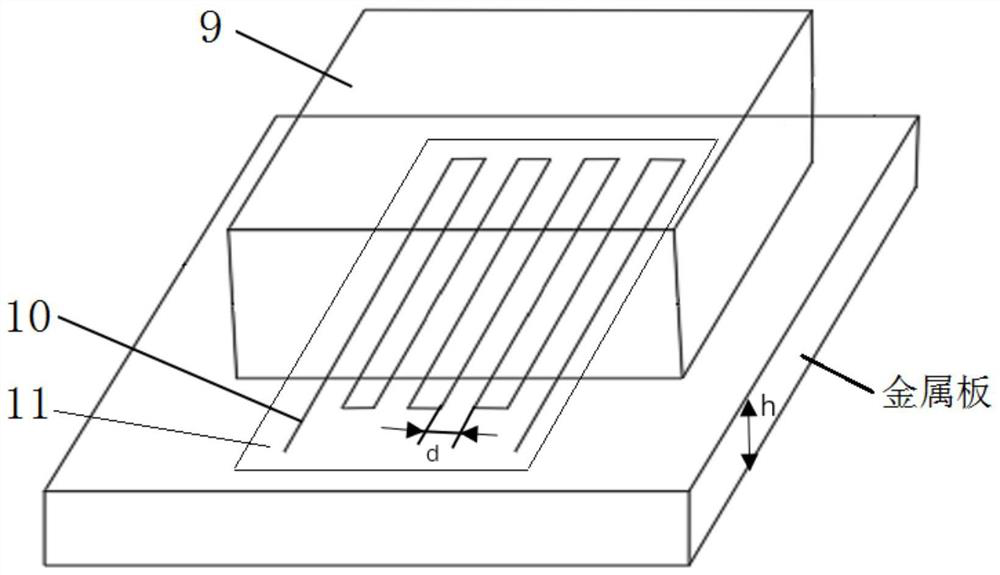

[0059] In this embodiment, a 6061-style aluminum plate with a thickness of 1 mm is used, and its size is 600 mm in length and 60 mm in width.

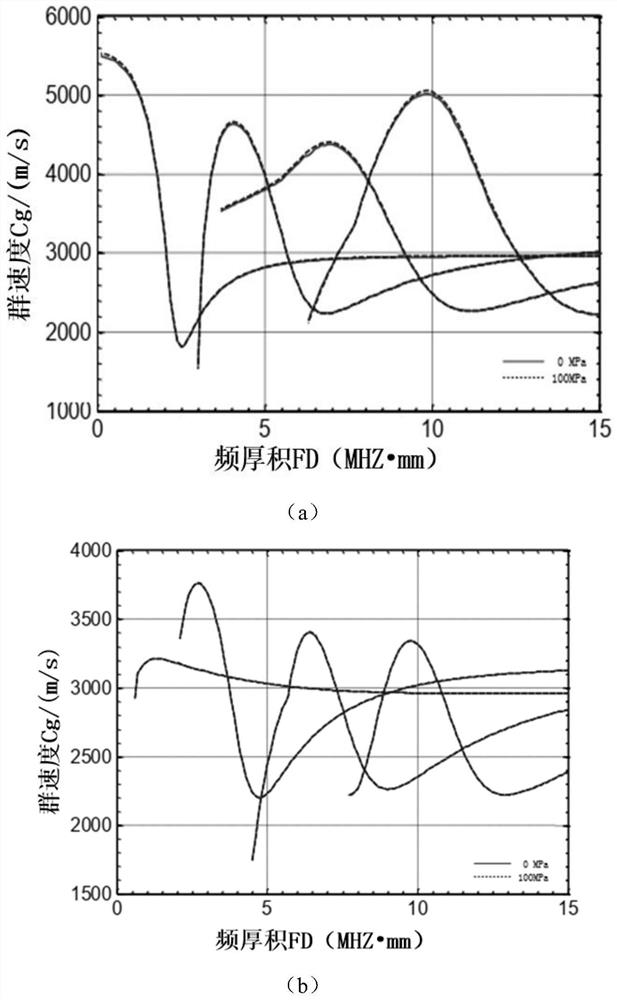

[0060] (1) Adopt MATLAB simulation to calculate the dispersion curve of each mode of the Lamb wave in the aluminum plate under different stresses; Described each mode comprises basic mode S0 and A0 and first-order mode A1 and S1;

[0061] (2) According to the propagation characteristics of the fundamental mode and the first-order mode of the Lamb wave, respectively select the cut-off frequency of the cut-off stage in the dispersion curve of the S0, A0, A1 and S1 modes of the Lamb wave (that is, the frequency of the maximum change in velocity ),according to image 3 It can be seen that the cut-off frequency of the S1 mode is 3MHz, the S0 mode is 1MHz, the A0 mode is 2MHz, and the A1 mode is 2.2MHz; the frequency-thickness product of each mode is calculated; the frequency-thickness product is 3MHz. mm, the S1 mode group has the slowest ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com