Breakage-proof solar cell strength detection device

A solar cell, strength detection technology, applied in the direction of measuring device, strength characteristics, using a stable bending force to test the strength of materials, etc., can solve the problems of inaccurate detection results, damage, reduce detection efficiency, etc. Efficiency, comprehensive detection results, and the effect of reducing detection loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

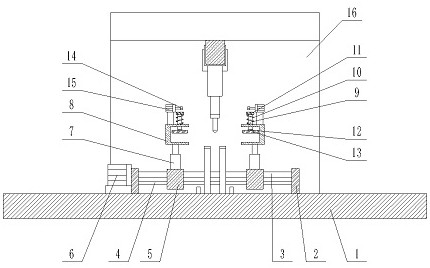

[0026]SeeFigure 1-4, An anti-damage solar cell strength detection device, comprising a base 1, two sets of first bearing seats 2 symmetrically distributed on the upper surface of the base 1 are fixedly installed in the middle, and a first wire is installed on the first bearing seat 2 to rotate together Rod 3, the left end of the first screw rod 3 passes through the first bearing seat 2 and is fixedly connected with a first motor 6 located on the upper surface of the base 1. Two sets of symmetrically distributed first moving blocks 5 are rotatably mounted on the first screw rod 3 , The first bearing seat 2 is jointly fixedly installed with a guide rod 4 located under the first screw rod 3 and passing through the first moving block 5, and the upper surface of the first moving block 5 is fixedly installed with an electric telescopic rod 7, and the electric telescopic rod 7 A U-shaped clamping seat 8 is fixedly installed. The upper surface of the clamping seat 8 is slidably installed wi...

Embodiment 2

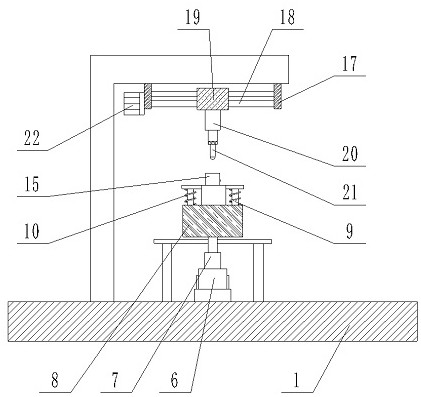

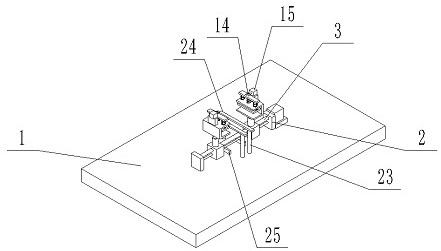

[0028]On the basis of the first embodiment, a vertical hydraulic cylinder 20 is fixedly installed at the lower end of the second moving block 19, a pressure sensor 12 is fixedly installed at the lower end of the hydraulic cylinder 20, a detection rod 21 is fixedly installed at the lower end of the pressure sensor 12, and the upper surface of the base 1 Four sets of centrally symmetrically distributed pillars 23 are fixedly installed in the middle, two sets of support plates 24 are fixedly installed at the upper ends of the left and right sets of pillars 23 on the same side, and two sets of support plates 24 are fixedly installed in the middle of the upper surface of the base 1 and located directly below the first screw 3 And the limit plates 25 are symmetrically distributed.

[0029]The working principle of the present invention is: the solar cell is placed on the support plate 24, the first motor 6 is turned on, and the first motor 6 drives the two sets of first moving blocks 5 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com