An electric heating oil pipeline

An electric heating technology for oil pipelines, applied in the direction of drill pipes, casings, boreholes/well components, etc., can solve the problems of low utilization rate of heat, time-consuming and laborious, bloated structure, etc., to improve anti-corrosion performance, ensure Heat tracing effect, effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

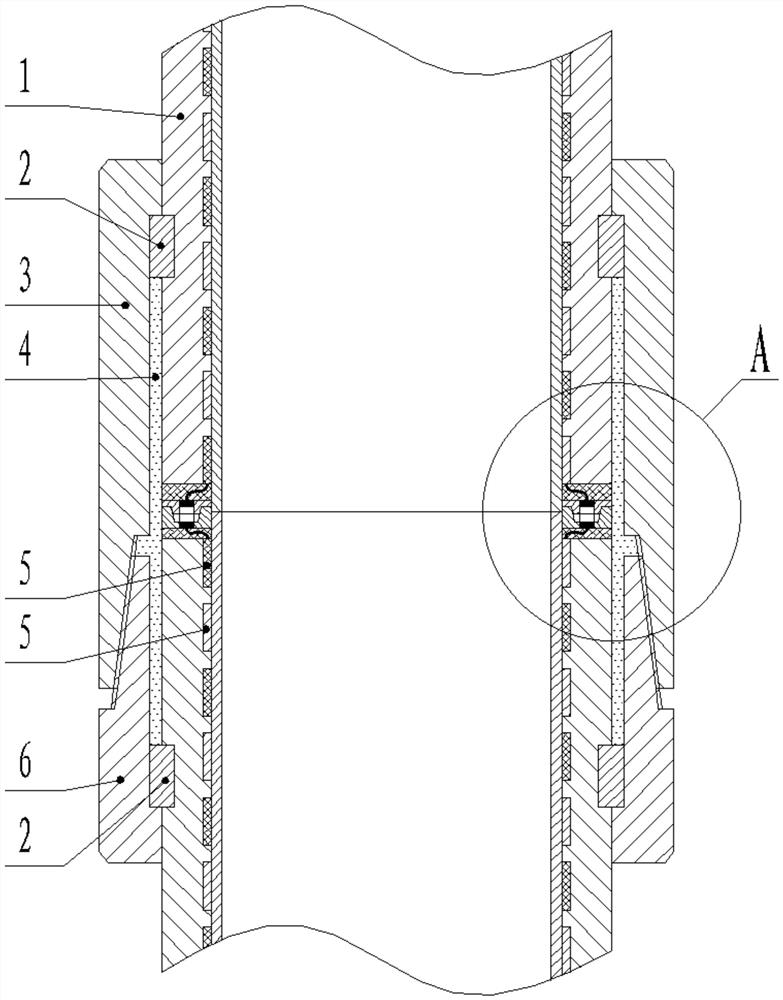

[0027] Such as figure 1 As shown, the present invention includes an oil pipe body and a coupling assembly, and two adjacent oil pipe bodies are connected through the coupling assembly. The above are common structures in the prior art, and will not be repeated here.

[0028] Such as figure 1 As shown, the oil pipe body includes a base layer 1 made of carbon steel, and the inner side of the base layer 1 is processed with two helical grooves of the same size that do not intersect each other (the two helical grooves can be called double-ended helical grooves together) , each of the two spiral grooves accommodates an electric heating band 5, and the two electric heating bands 5 spirally coil along the inner wall of the base layer 1 and extend to both ends of the base layer 1, and each end of each heating band 5 is connected with a wire The terminal 11 and the connection termi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com